The space frame structure is a high-order hyperstatically indeterminate structure, its node structure is simple, its component production is factory-processed with high precision, and its construction period is short. widely used in construction.

Introduction to 1space frame design software

At present, the space frame structural design software developed in China includes MSTCAD of Zhejiang University, SFCAD developed by Beijing Yunguang Architectural Design Consulting and Development Center, MSGS of Construction Research Institute, 3D3S of Shanghai Tongji University, and TWCAD of Shanghai Jiaotong University. Design and processing are more convenient and quicker. In this paper, mainly take the MSTCAD software of Zhejiang University as an example to address the problems that designers often have, and put forward corresponding solutions.

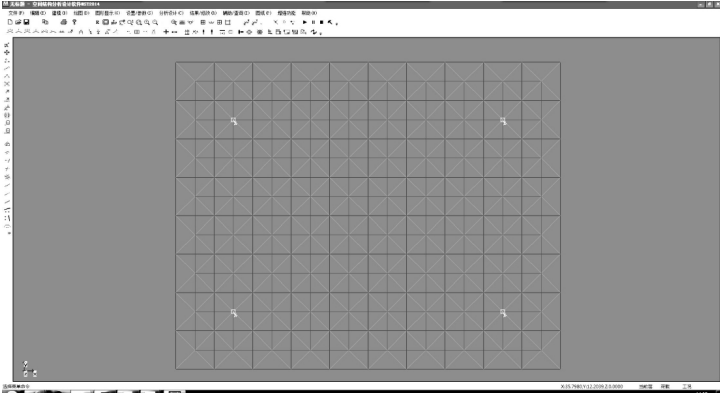

The MSTCAD software interface is shown in the figure below.

2 Analysis of common problems in several types of design

2.1 The specification of the space frame bar exceeds the aftermarket model

The diameter specifications of the space frame rods used in some bolt ball space frame construction drawings are Φ45, Φ50, Φ54, Φ63.5, Φ68, Φ102, Φ150 and other special specifications. Rods of these specifications are difficult to buy corresponding accessories such as cone heads and sealing plates in the current space frame market, and require special customization, which should be avoided as much as possible; rods with diameter specifications commonly used in the space frame market, such as Φ48, Φ60, Φ76, Φ89, Φ114, Φ140, Φ159, Φ180, Φ219 and other diameter specifications.

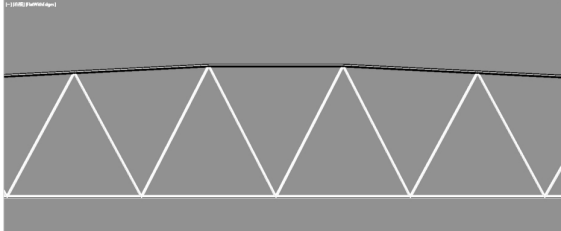

2.2 There is no ball node at the ridge of the double-slope space frame (it is easy to cause water accumulation). Some double-slope flat space frames may not have ball nodes at the ridge of the upper chord due to the difference in the upper chord division of the space frame, which makes the structure of the roof node at the ridge complex. The construction is cumbersome and it is easy to cause poor drainage of the roof ridge (as shown in the figure below).

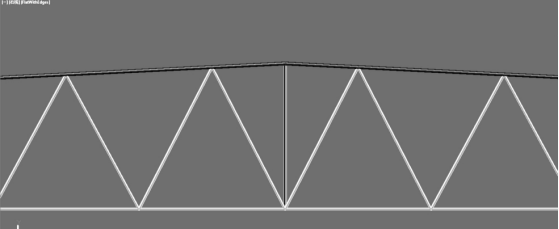

In this case, it is suggested to add a row of ridge top chord nodes and then connect with the bottom chord nodes to form a geometrically invariant system, and re-analyze and calculate; in this way, the method of ridge nodes on the roof is relatively simple and does not accumulate Water hazards (as shown in the diagram below).

2.3 Insufficient pressure of the sleeve when designing the space frame

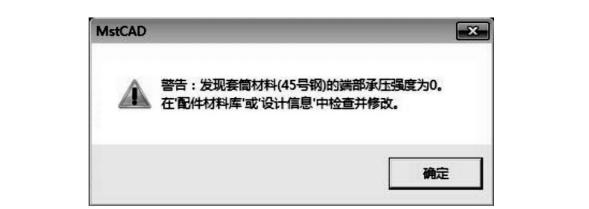

When using MSTCAD software to design the bolt ball, it often prompts that the sleeve is under-pressurized (as shown in the figure below).

Due to the material information of MSTCAD software, the material data of No. 45 steel needs to be filled in by the designer to calculate the bolt ball; The contact between the balls adopts the end face pressure (planing and top tightening), and the material of the large-diameter sleeve is No. 45 steel. However, there is no allowable stress data for the end face pressure of No. 45 steel in the current steel structure code. In the mechanical manual, there is only The yield strength of No. 45 steel has no section bearing allowable stress. The yield strength of No. 45 steel is similar to that of Q355 steel, so the design strength of Q355 steel’s end face pressure of 400N/mm2 can be applied; however, due to construction and installation errors, the sleeve and the ball may not be completely flat, and the end face pressure strength can also be applied. , it is recommended to reduce its strength, and a reduction factor of 0.9 can be taken. Only the necessary data of No. 45 steel is input, and after the model is analyzed, the software can design the bolt ball.

2.4 space frame sagittal height is too thick, the aesthetics is reduced

Some designers simply pay attention to the safety of space frame calculations. After the design is completed, the thickness of the space frame is too thick. Although the structural deflection meets the specifications and the safety requirements are met, the space frame is too thick. The small size also makes the amount of structural materials wasted, and those who need it should pay enough attention. An excellent design engineer usually needs to make multiple corrections and calculations on the thickness of the space frame structure to achieve safety, economy and beauty, and it is not suitable to do it in one step.

2.5 The space frame abdominal member of the support part touches the concrete column

This usually occurs when the space frame support is located at the top-chord ball node, and the designer tends to ignore the check calculation of the gap between the upper-chord ball node and the bottom-chord ball node at the support position and the concrete column. Show.

At this time, try to avoid blindly increasing the height of the support. You can move the lower string ball node connected to the end of the web bar of the support left or right or up and down to a suitable position, and perform physical observation in Autocad. When it is confirmed that there will be no interference, re-analyze the calculation Just pass it (as shown in the picture on the right).

2.6 Space frame structure high-strength bolts start with M12

Too many M12 high-strength bolts are used in the material table of the space frame structure, which often occurs in the 3D3S space frame design software. Some designers are new to space frame design, but do not understand the use of the space frame accessories market, so they start to configure the minimum bolt .M12 set by the program, which often leads to repeated designs later. Although there are M12 high-strength bolts in the current “Technical Regulations for Spatial Grid Structures” (JGJ7-2010), they are also the limit specifications for space frame bolts. If it is not a very small special project, high-strength bolts above M16 are generally used, otherwise the market Not to mention that it is difficult to buy in the market, such small bolts are easy to be brittle and broken when installed on site.

This paper analyzes several common problems in the space frame design of bolted ball joints, and proposes solutions for reference. Through the analysis and discussion of this article, the following conclusions and suggestions can be made for the reference of engineering and technical personnel.

① The interference review work between the abdominal members and the concrete columns should be strengthened. If there is interference, measures can be taken to increase the elevation of the lower string ball joints or change the horizontal position of the lower string ball joints. Try to avoid blindly raising the support.

② A volleyball node should be arranged structurally at the roof ridge of the double-slope space frame to facilitate the drainage node of the roof ridge.

③ The mechanical data of No. 45 steel should be used reasonably.

④Reasonably control the height of the space frame, and constantly correct the height of the space frame, so that the structure of the space frame is safe, economical and beautiful.

⑤ It is necessary to have a deep understanding of the specifications of the commonly used rods of the space frame and the commonly used accessories in the market, so as to avoid repeated designs in the later stage.

About Us

About Us 2023-05-11

2023-05-11