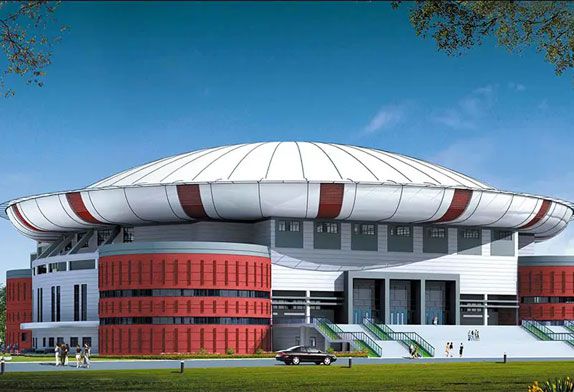

1. Project Overview

A gymnasium (main building) has a building area of 14813.75m², a building span of 81.8m, and a height of 26.1m. The roof structure adopts the form of a hyperboloid steel space frame, and the steel space frame adopts a quadrangular pyramid space frame structure with bolt balls placed upright, with peripheral support, and a total of 88 supports are set. The support of the space frame is selected from the tensile fixed spherical joint support. The perimeter of the space frame cantilever canopy is 14.95m, and there are 3 layers of space frame at the cantilever. The length of the net frame is 124.67m, the width is 111.70m, and the span is 81.80m. The projected area of the net frame structure is 10937.29m2. The structural design service life is 50 years, the durability of the main structure meets the requirements of 50 years, and the structural safety level is two. The plane shape is elliptical, the facade shape is a hyperboloid arc, and the overall shape is beautiful and generous.

2. Characteristics of segmented high-altitude bulk installation technology of steel space frame

2.1 Simple and practical operation

The stadium steel structure design adopts the segmented high-altitude bulk construction, which is the construction method of the steel space frame structure, which is assembled from the side of the space frame structure on the working platform by the external expansion method, and then the unit space frame is

assembled by lifting tools until it is installed to the support. Through the practical inspection of the project, it is proved that the steel space frame adopts the segmented high air bulk construction, which is beneficial to meet the requirements of the engineering quality and the construction period, simplifies the construction process, shorter the construction period, reduces the cost, and achieves a better economy. Technology has the significance of popularization.

2.2 Reduced probability of construction accidents

Compared with the hoisting method and high-altitude segmented splicing and sliding method, this method avoids safety accidents caused by falling heavy objects, and can also effectively prevent the deformation of the steel space frame and reduce the risk factor in the construction process.

2.3 Save costs and increase speed

When using the segmented high-altitude bulk method to install the steel space frame, there is no need for large construction equipment such as a crane, which saves a sum of construction and installation costs, and the installation speed is greatly improved compared with the hoisting method.

2.4 shortened construction time

When building a steel space frame at a high altitude, the construction site is relatively small, and the steel space frame is connected in sections first, which can save space, and then use the special cantilever picker transports the segmented connected steel space frame, saving again Manpower and material resources have accelerated the installation progress and shortened the construction time.

3. Key points of technical control during construction

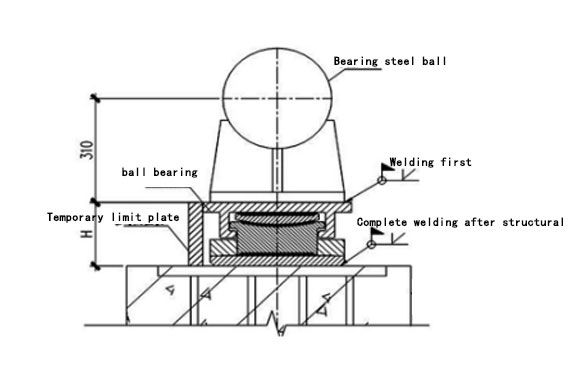

3.1 Installation of ball hinge support

One of the key points and difficulties in this project is the installation of the ball hinge support of the space frame. There are 88 spherical hinge supports in total, which are fixed hinge supports and can rotate in two directions. If the rotation angle is not well controlled, it will cause excessive deflection of the space frame or deformation of the rods. Therefore, during installation, the ball joint support must be installed first and temporarily fixed. The installation diagram is shown in Figure 1.

Figure 1 Installation diagram of ball joint support

The specific installation process is as follows:

1)When installing the space frame, first install the ball joint support, and after the positioning is correct, the ball joint support and the embedded parts are connected by electric welding.

2)The outer side of the spherical hinge support is limited by a temporary limit plate, and the limit plate is welded to the embedded part.

3)The space frame support is installed on the spherical joint support and welded according to the requirements of the drawings.

4)After the installation of the space frame structure is completed, and the inspection of various indicators meets the requirements of the design and specifications, the ball joint support can be welded. After the welding of the ball joint support is completed, the temporary limit plate can be removed or kept in place forever.

3.2 Steel space frame installation

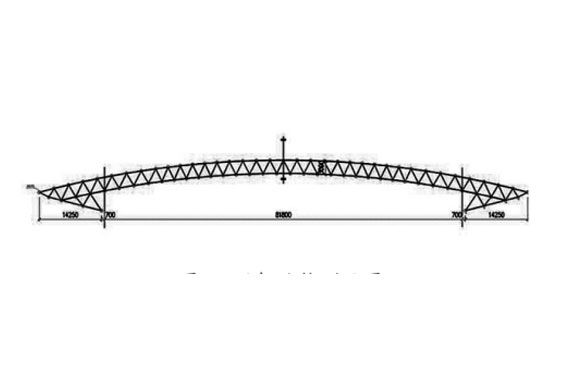

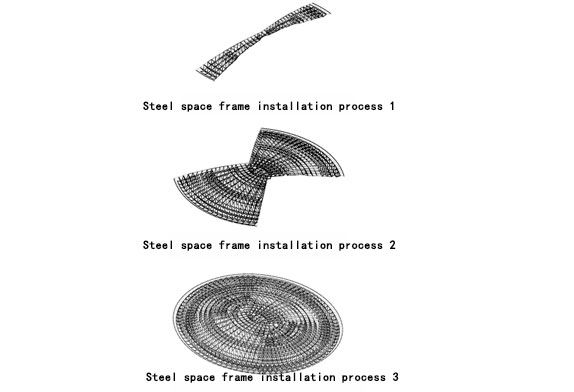

According to the characteristics of the project, the span is large and the construction period is tight, the project adopts cross-flow construction, the installation platform is set up by the full hall of high support mold scaffolding, and the high altitude bulk method is used for installation. Although the amount of steel used for the network frame of this project is not large, the form of the network frame is an elliptical shell hyperboloid structure. If the overall vertical lifting method of ground assembly is used for construction, not only a large number of synchronous lifting equipment and technologies are required, but also because the force of each lifting point is different from that of the original space frame during lifting, it is necessary to re-analyze the force of the space frame, which will cause the space frame to be damaged. The increased amount of steel. In addition, since it is difficult to avoid the deformation of the space frame structure due to the work of lifting, replacing, and filling vacancies, which has a certain impact on the quality, the overall lifting method of ground assembly cannot be used in this project; the advantage of the high-altitude assembly of the high-support formwork scaffolding is that there is no technical Difficulty, safe and reliable construction, small deformation of the space frame in place, easy to guarantee the quality, but the installation and dismantling of scaffolding requires a large amount of work and takes up the construction work area of other types of work, so the construction progress must be reasonably arranged to ensure that the construction period can be completed on time. Figure 2 shows a cross-sectional view of the space frame structure.

Figure 2 Cross-sectional view of the space frame structure

The installation of the steel space frame in this project adopts the installation method of high-altitude assembly of full-scale high-support formwork scaffolding. A full-scale high-support formwork scaffolding is set up in the area of the steel space frame indoor plane area of 4480m2. 4 installation groups, take the short axis of the elliptical shell as the axis of symmetry, and 2 installation groups on each side face the two directions of the long axis and bulk up at high altitude (see Figure 2 for the installation process of the steel space frame for details). During the installation process of the space frame, the spherical hinge support needs to be temporarily fixed. After the space frame is completely installed, the spherical hinge support of the space frame is fully welded, and the construction of the roof steel purlin and other parts is started.

About Us

About Us 2023-01-29

2023-01-29