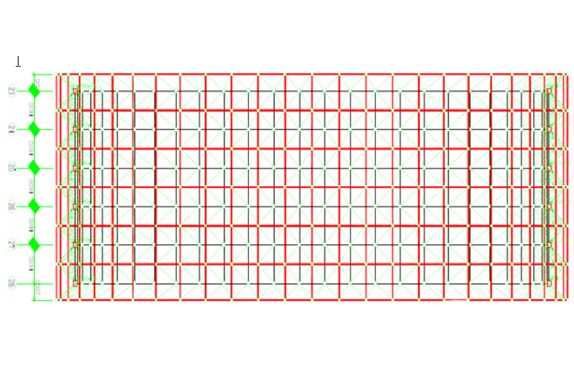

The project is the main structure space frame project of the dry coal shed of the power plant. The projected area of the space frame is about 18,000 square meters. The project structure adopts bolt ball joints, and high-strength bolts to connect rods, and is placed in a square pyramid. The space frame is supported by the concrete column. top. The vertical height is 40 meters and the span is 74 meters of the arched cylindrical shell space frame. The roof is made of 0.6mm thick aluminum-zinc color profiled steel plate, and a lighting belt is set in the middle. Its installation process is relatively difficult. The scope of this construction includes the production, transportation, and installation of the space frame, the anti-corrosion of the roof structure, and fire prevention.

The installation method of the space frame should be adjusted according to local conditions, that is, it is more characteristic of the force and structure of the space frame, and is comprehensively determined in combination with the conditions of the construction site under the requirements of quality, safety, progress, and economic benefits. The installation methods are as follows: 1. High-altitude bulk method 2. High-altitude bulk method – cantilever construction method 3. Sectional and block installation method 4. High-altitude sliding method 5. Overall hoisting method.

According to the span, supporting conditions, supporting elevation, construction period, installation cost, technical requirements and other factors of the space frame project, the column top elevation of the space frame of this project is about 8 meters, and the overall structure is a cylindrical shell space frame. It is suitable to adopt the installation scheme that combines strip hoisting, ground assembly, and high-altitude cantilever installation. Past engineering practice has proved that as long as the scheme is reasonable and careful planning and preparation beforehand, it is completely possible to achieve “safe, fast, efficient and civilized”. Require. The characteristics of choosing this scheme are 1. It can save the waste of manpower, material resources, and materials; 2. It can reduce the personal safety of construction workers working at heights; 3. The construction period is fast; 4. The ground assembly can effectively control the deflection of the space frame during installation, more conducive to controlling the quality of the project.

About Us

About Us 2022-05-18

2022-05-18