1. Project Overview

In order to meet the needs of the building space for a stadium roof project, the bottom of the prefabricated stadium project adopts a frame structure, and the roof truss adopts a space frame structure. The project has one basement floor and three floors above ground, with a total height of 24m, a total construction area of 10,600 square meters, and 3,460 fixed seats. The space frame is oval in shape, with a total coverage area of 8,380 square meters, with a long axis of 109.6 meters and a short axis of 67.8 meters. The roof system mainly adopts double-layer color steel composite panels, and partially adopts double-layer transparent laminated glass lighting belts. Using an aluminum plate.

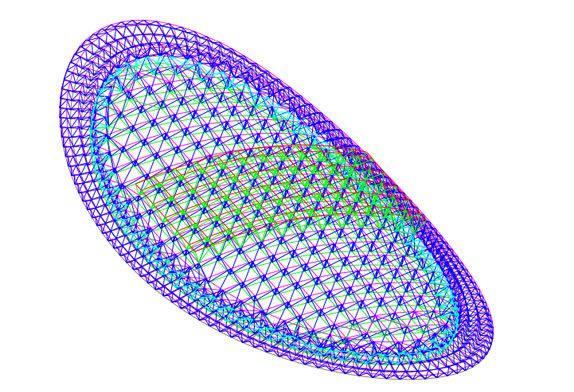

FIG. 1 3D view of the prefabricated stadium space frame structure

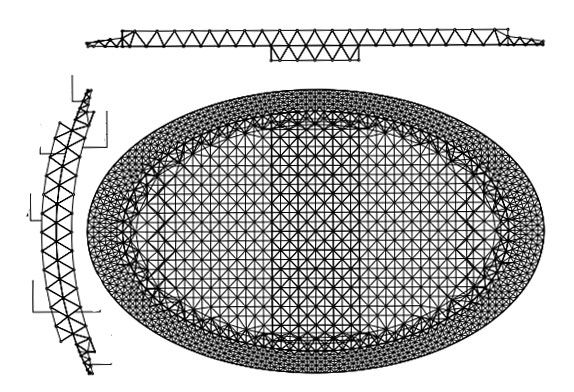

FIG. 2 Plane and elevation of prefabricated stadium space frame structure

2 Space frame selection

The plane shape of the prefabricated stadium is oval, and it is supported by the lower chord. According to the regulations of “Design and Construction Regulations for space frame Frame Structure” (JGJ7-91), when the side-to-length ratio (long side/short side) of the rectangular peripheral supporting space frame is greater than 1.5, it is advisable to use a two-way orthogonal placement. space frame, positive quadrangular pyramid space frame, or positive evacuated quadrangular pyramid space frame. Among them, the number of nodes and rods of the square pyramid space frame is the least, the steel consumption is the most, and the roof drainage treatment and skylight setting are also more convenient. From the perspective of stiffness characteristics and mechanical performance, the space stiffness of the positive square pyramid space frame Compared with other quadrangular pyramid space frames and two-way orthogonal positive space frames, the force is relatively uniform and the ductility is better.

The splicing and installation method of the space frame has a significant impact on the selection of the space frame and the cost and duration of the entire project. The construction requirements should be taken into account when selecting the type of space frame so that the space frame structure can be safe, economical, and reasonable. The construction site of the project is small and cannot be assembled on the ground. The construction plan can only use the high-altitude bulk method or the high-altitude sliding method. If the high-altitude bulk method is adopted, the construction needs to set up full-scale scaffolding, the period is long, and the construction cost is high. The high-altitude sliding method can avoid this problem. The upright quadrangular pyramid space frame to be used in this project can be constructed by the high-altitude sliding method. This method meets the requirements of the site conditions, the equipment is simple, and the construction is convenient.

In order to comprehensively compare the mechanical performance and economic performance of the positive-placed quadrangular pyramid space frame and the positive-placed evacuated quadrangular pyramid space frame, the model design and analysis of the two structures will be carried out at the same time, and the better one will be selected on the basis of comprehensive comparison. for actual engineering.

After a series of comparative analyses, it is concluded that the large-span space frame project of a gymnasium adopts the positive-placed quadrangular pyramid space frame structure and the positive-placed evacuated quadrangular pyramid space frame structure, and selects bolt ball joints and welded ball joints respectively:

①For the large-span complex space frame structure, the rigidity of the evacuated quadrangular pyramid space frame is low, the force is not uniform, and the overall force performance and deformation performance are worse than that of the positive quadrangular pyramid space frame. There is no saving of steel, so the long-span complex space frame structure is not suitable for the positive evacuated quadrangular pyramid space frame.

②The basic period of the two systems of the positive-placed quadrangular pyramid space frame and the positive-placed evacuated quadrangular pyramid space frame is relatively close. On the whole, all the natural vibration periods of the evacuated quadrangular pyramid space frame system are larger than those of the positive placement quadrangular pyramid space frame system, and the stiffness of the evacuated quadrangular pyramid space frame system is greatly reduced, which is not conducive to earthquake resistance.

③ The mode shapes of the two systems of the positive placement quadrangular pyramid space frame and the positive placement evacuated quadrangular pyramid space frame is mainly vertical modes, but the 3-9 mode shapes of the positive placement and evacuated quadrangular pyramid space frames all appear the local mode shapes of the rods, indicating that the positive-placed evacuated quadrangular pyramid space frame is prone to local damage under the condition of high vibration mode, causing the overall damage of the structure, which is not conducive to earthquake resistance.

④ The joint form has little effect on the mechanical performance and economy of the space frame structure, so only the construction factors can be considered when selecting the structural joints. Generally, bolt ball joints are used more because of their convenient construction and guaranteed quality.

About Us

About Us 2022-09-28

2022-09-28