1. Project overview

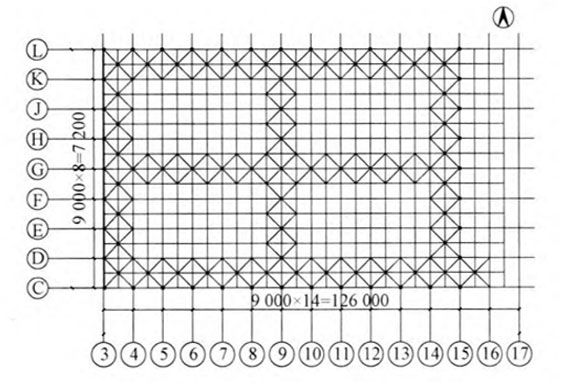

The upper space frame of Hebei Olympic Sports Center Gymnasium is a peripheral supporting plane space frame. The space frame span is 72.0 m, the length is 121.2 m, and the end cantilever is 13.5 m. , supported on the lower concrete column through the finished bearing, the layout of the space frame is shown in Figure 1. The space frame is an orthogonal upright space frame, with a thickness of 4.0 m and a grid size of 4.5 m x 4.5 m. The space frame members and joint welding balls are made of Q345B.

Figure 1 Gymnasium space frame layout

2. Construction features of the project

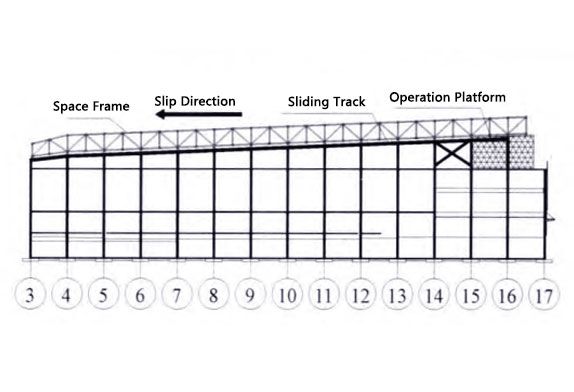

The space frame is a peripheral supporting plane grid with a span of 72.0m. Before the construction of the space frame, the lower concrete structure (including the stand) has been completed, and an open and flat ground space has not been formed. It is not feasible to lift the whole space frame after ground assembly and to use the sliding operating frame to carry out the in-situ sliding assembly construction at high altitudes, and the lower space of the space frame is larga e. If the scheme of installing the in-situ mounting network frame at high altitude with a full operating frame is adopted, the installation volume of the operating frame is large and the economy is not good. This project adopts the construction method of setting up an operation platform at one end of the space frame cumulative slip construction scheme, and arranging two slip tracks on the south and north sides of the space frame, assembling the space frame in blocks on the operating platform and accumulating sliding to the design position. The space frame sliding facade layout is shown in Figure 2. The sliding track is used for the cumulative sliding of the space frame; a hydraulic crawler is arranged as the sliding power equipment of the space frame; two tower cranes are arranged for the assembly and feeding of the space frame.

Figure 2 Space frame sliding facade layout

3.Slip construction technology

The sliding rail was arranged, the sliding unit network frame was assembled on the scaffold assembly platform, the sliding boots were installed on the welding ball of the support of the network frame, and the hydraulic tractor (pusher) was used to push the sliding unit of the network frame forward to slip 9m(i.e. the width of the sliding unit) and move out of the scope of the assembly platform. According to the above method, the assembly and sliding construction of the remaining space frame sliding units shall be continued. The slide rails shall be removed and the space frame shall be temporarily supported by jacks, the pedestals shall be jammed, and the space frame shall be positioned. The construction of space frame sliding shall be completed.Slide process is shown in Figure3.

|

Embedded bearing plate and sliding track embedded parts |

↓

|

Sliding assembling platform and sliding track layout |

↓

|

Sliding space frame unit assembly |

↓

|

Successive accumulative slip of space frame elements |

↓

| Removal of slippage track and slipper Jack back, finished support plug |

↓

|

The slip measures are removed and the slip construction is completed |

Figure 3 Sliding construction of space frame

“Hydraulic synchronous push-slip construction technology” is used for the construction of large-span space frames. The sliding process is controlled by computer synchronous control, with high synchronization of sliding, minimal acceleration of hydraulic system transmission, and safe and controllable sliding. Hydraulic synchronous pushing equipment and facilities have small volume and weight, strong maneuverability, convenient reverse transportation and installation, reasonable arrangement of sliding pushing point, track and other sliding facilities, a small amount of space frame installation measures, and economic and reasonable.

About Us

About Us 2022-06-24

2022-06-24