1 The toll station is no longer just a place for toll collectors to work

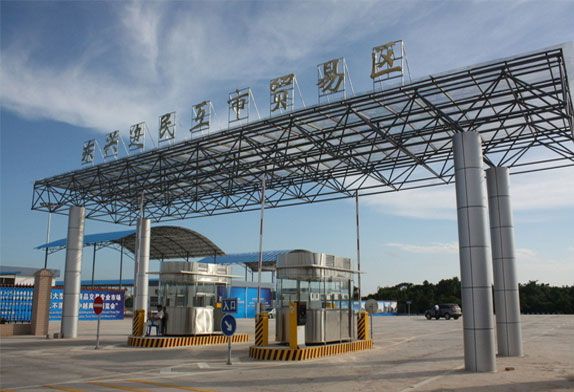

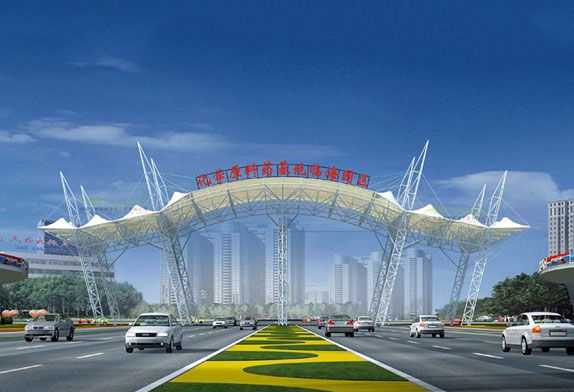

With the modernization of the expressway, the toll station has also been given more modern meanings and has become one of the architectural symbols of the city, so the earlier concrete structures have been replaced by large-span space steel structures. The main part of the toll station is a large canopy, so the quality of the structure selection of the large canopy is related to the use quality of the entire toll station. According to the use function of the toll station, the width of the vertical road surface of the canopy of the toll station should be larger than the width of the road surface where the canopy is set. At the same time, in order to ensure the smooth passage of vehicles, the clear height of the toll canopy should be more than 5.5m. In the structural form of the toll station, the plane projection shape is mostly rectangular, and the square plane form rarely appears. Secondly, the toll station generally no longer sets the support column within the width of the road surface but sets it outside the width range, which is to meet the needs of vehicle traffic.

2 Steel structure content and characteristics

The steel structure is a type of structure that uses steel as the main raw material for production and processing. It is a widely used building type in the construction field. This type of structure has the characteristics of lightness, high strength, and good seismic performance of steel material, and the basic cost is low. , Easy installation, fast construction, short construction period, fast return on investment, and less pollution caused by construction. The utilization rate of steel structure buildings has become one of the symbols to measure the level of national economic development, and steel structure facilities are even the embodiment of national economic and technological levels. At the same time, the steel itself has good ductility, so it can offset part of the seismic energy in the event of an earthquake, and the safety and stability of the structure are high. In addition, the steel structure can be prefabricated in the workshop, which reduces the workload on site and naturally reduces the pollution to the surrounding environment. However, steel structure construction is also more susceptible to corrosion due to the influence of the external environment, so maintenance work in the later stage is very important. The maintenance and construction cost of steel structure buildings is higher, and the overall cost is higher than that of concrete structures.

3 Common steel structure forms of expressway toll stations

The common long-span space steel structure forms of expressway toll stations include light steel structures, plate-like space frames, space-reticulated shell structures, prestressed cable-stayed space frame structures, and locking membrane structures. Among them, the light steel structure is a structure with rigid nodes, which has a large internal space and a small number of rods. Secondly, the steel structure of the flat space frame can be divided into a double-layer space frame structure and a three-layer or multi-layer space frame structure according to the number of layers. The three-layer or multi-layer space frame increases the height of the space frame and reduces the space frame size. The pressure and length of the rod are reduced, making it easy to manufacture and install. According to the support conditions, it can be divided into peripheral support, point support, and a combination of the two. Generally, the amount of steel used is small, and it is a structural form with a better economy. The space-reticulated shell structure has the advantages of beautiful shape, good mechanical performance and technical economy, and can adapt to the changing requirements of the toll station architectural shape. The prestressed cable-stayed space frame structure connects the space frame or reticulated shell with the tower column so that the stress of the space frame or reticulated shell structure is more reasonable. The cable-membrane structure is a brand-new structural form, with suspended and skeleton structures. It uses steel cables and steel components as the main load-bearing system to transmit the external load force. It has a high degree of plasticity, so it can adapt to the diversity of architectural shapes. It has the advantages of light weight, good light transmission and strong modernity.

4 Problems need to be paid attention to in the design and construction of the spatial steel structure of the expressway toll station

4.1 Structural selection and structural arrangement according to actual needs

In the design and construction of the steel structure of the toll station, the appropriate steel structure should be selected according to the specific layout of the toll station, the conditions of the construction site, the weight of the steel structure, etc., the hoisting equipment should be arranged in a reasonable and accurate position, and the length of the steel beam and steel column should be controlled at the same time. and width, so that the steel structure components can ensure the safety and reliability of installation and disassembly during hoisting.

4.2 Do well in the design of connection nodes

When designing the steel structure toll station, regarding the design of the welded joints of the steel column of the steel structure, a certain installation distance needs to be set aside for the convenience of installation and construction. As for the selection of gusset plates and the connection design of beams and columns, there are mainly three types of end plates: vertical end plate, horizontal end plate and oblique placement. Vertical placement is mainly used for the connection of cross-section columns, and when the vertical load can play a certain control role, the horizontal placement of the end plates can effectively control the force on the connecting nodes. When the bending moment of the node is large, the end plate is placed obliquely, which can properly extend the moment arm of the anti-bending connection, which is helpful for arranging the bolts. There are two types of end plate splicing: outrigger type and flush type. Compared with these two methods, the force of the former joint is more in line with the mechanical principle, and the bearing capacity is much higher than that of the flush joint. Therefore, in practice, the overhanging end plate connection is used more. When setting the overhanging part of the gusset plate, the stiffeners can make the bolts close to both sides of the tension flange become uniform, so that the shear resistance of the joint can be improved, and the deformation effect of the gusset plate can be effectively reduced.

4.3 Do well in the design of the support system

In order to ensure the space work of the steel structure building, improve the overall rigidity of the building steel structure, so that the steel structure can effectively withstand horizontal and longitudinal forces, and avoid the deformation and instability of the rods, it is necessary to combine the specific type, use, and specific form of the building structure. Support system, including column support and roof support system. Among them, in the design of the roof system, attention should be paid to the span, height and arrangement of the column network of the building structure and the form of the roof structure, and the horizontal and vertical supports and tie-rod structures should be set well.

4.4 Do well in design measurement control and calibration

In order to ensure the rationality of the selection and design of the steel structure of the expressway toll station, so as to ensure the quality of the later installation and construction, it is necessary to do a good job in the control of the design and measurement work during the design. It is required to control the verticality and elevation deviation, and a detailed and reasonable control management plan should be formulated in combination with the past design and construction experience and the actual project of this project when measuring and controlling. After the design is completed, measure the single steel column structure, and timely find the places with serious axis deviation, large verticality and elevation deviation, and make corresponding adjustments and modifications according to the design requirements.

4.5 Do well in quality inspection, including repeated calibration of reference points, elevations and control nets, etc.,

to ensure that every small bolt, the distance and height difference between each group of bolts, etc. meet the design requirements. In the design of the main body of the steel structure, attention should be paid to setting quality control points, and at the same time reasonably setting construction procedures and key projects, and finally to supervise and control common quality problems.

4.6 Use segmented installation of steel beams Because the overall weight of the steel beams is too heavy and the span is too large

The segmented construction method should be adopted in the actual construction and installation, and the steel beams are divided into three sections and installed in the way of aerial docking. Before hoisting, the steel beams are spliced into three sections on the ground, and then hoisted with a 50T truck. After the splicing of the steel beams QL-4 and QL-6, one end is connected to the steel column end with a temporary installation splint, and one end is temporarily fixed on the support frame. . After the steel beams QL-1 and QL-2 are spliced, they are hoisted by a 50T truck. One end is connected to the end of the steel column with a temporary installation splint, and one end is temporarily fixed on the support frame. The rest of the other steel beams are installed in a similar manner until the end of the assembly.

5 Conclusion

To sum up, the performance and structural characteristics of expressway toll stations determine the toll canopy of the main part of the toll station. Its plane form is rectangular, and its support method is point support. Through practical analysis and force analysis of different steel structure forms, and taking into account factors such as economy, technology, transportation, and installation convenience, etc., the steel structure forms that are more suitable for the design and construction of steel structures of toll stations include plane space frame structure and double cylindrical reticulated shell structure. Especially when the span of the steel structure is large, the positive placement quadrangular pyramid cylindrical reticulated shell is preferred, and when the bearing capacity requirement is high, the positive placement evacuated quadrangular pyramid space frame is preferred. The economic performance of this structure is It is better to use less steel and at the same time meet the usage demand of the toll station.

About Us

About Us 2022-12-26

2022-12-26