There are three types of Brittleness associated with hot plating, namely: Hydrogen Embrittlement (HE), Liquid Metal Embrittlement (LME), and Strain Age Embrittlement.

What does that have to do with our title? What’s it got to do with cracking after galvanizing?

It matters a great deal! Lets proceed.

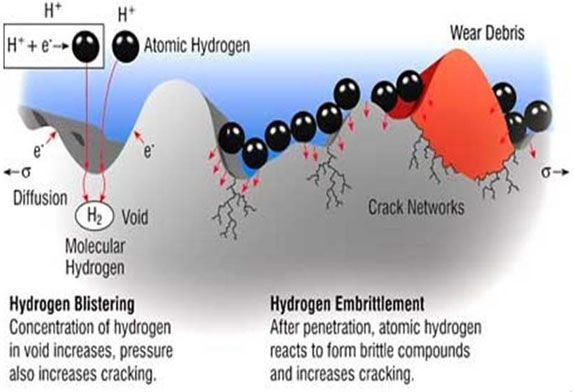

hydrogen embrittlement refers to a phenomenon where hydrogen atoms absorbed by the steel, accumulate between grains or in the location of defects, eventually cause the steel to crack.

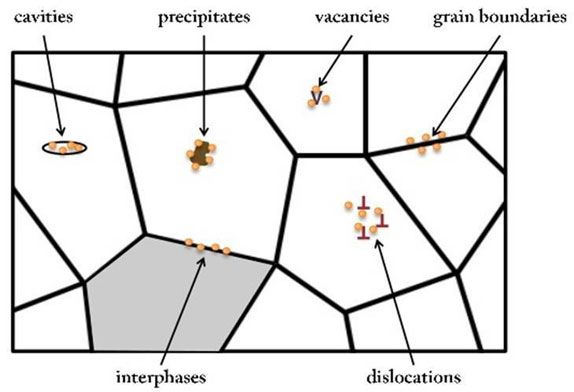

Figure 1: Hydrogen Atom Trapping Mechanism

Figure 2: Hydrogen Induced Brittleness and hydrogen bubble formation

Figure 2: Hydrogen Induced Brittleness and hydrogen bubble formation

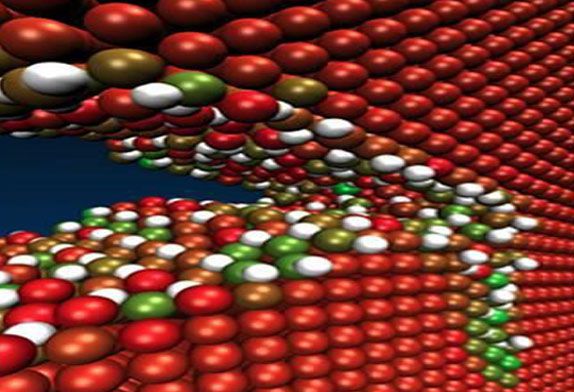

Figure 3: computer-simulated Cross sections of a metal micro-crack, white for hydrogen atoms (Photo:McGill University)

CRACKING CASE OF HOT DIP GALVANIZING

Although steel normally absorbs hydrogen during hot galvanizing, heated steel often loses hydrogen at high temperatures due to the high temperature of the zinc in the zinc pot.

However, under certain conditions such as, when the grain size of steel is too small, hydrogen atoms cannot escape even at the hot-dip temperature, which will lead to the accumulation of hydrogen atoms at the grain boundaries or defect locations. Local stresses at the grain boundary or at the location of the defect rise, and eventually cause the part to crack.

Figure 4: Hydrogen embrittlement in weld heat affected zone of high strength steel

Figure 4: Hydrogen embrittlement in weld heat affected zone of high strength steel

For steels with tensile strength less than 150KSI (1040MPA), the grain size is usually large enough to allow the escape of hydrogen atoms at high temperatures, but for steels with tensile strength greater than 150ksi (1040MPA), hydrogen atoms are likely to be locked between Grain Boundaries and not be able to escape, thus producing hydrogen embrittlement. Hydrogen embrittlement does not occur in a timely manner, and is observed only when the part is under load.

The strain-age embrittlement in hot-dip galvanizing occurs shortly after the hot-dip galvanizing is completed.

That is to say, strain-age Brittleness can be observed after hot plating, but hydrogen Brittleness cannot be observed after hot plating, but it can only be observed after the steel bears a certain load and lasts for a period of time.

Method of avoiding hydrogen embrittlement of Parts

- The simplest method is to select steels with tensile strengths below 150ksi (1040mpa), which as previously stated, have sufficiently large grain size to allow for the escape of absorbed hydrogen atoms at hot dip temperatures.

- When the HIGH STRENGTH STEEL PARTS HAVE TO BE HOT DIP, the hot dip process can be adjusted to reduce the probability of occurrence of hydrogen embrittlement. For example, shorten pickling time.

- In addition, an adjustable process includes mechanical cleaning of the parts (E. G. Shot peening) followed by rapid pickling (residence time in the pickling pit is not greater than 30s).

The goal of rapid pickling is to remove the residue from the shot-peening process, reduce the total amount of exposed hydrogen atoms in the steel parts, and reduce the chance of the hydrogen atoms being absorbed by the ultra-fine grains of high-strength steel.

About Us

About Us 2021-02-08

2021-02-08