1. Project Overview

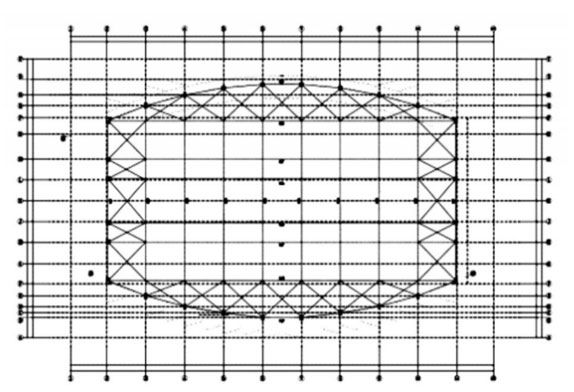

The total construction area of the stadium roof project is about 82353.3m². The stadium roof is a spatial steel tube truss structure with a maximum single span of about 50.7m(as shown in Figure 1). The top elevation of the truss is 22m, and the maximum weight of a single truss is 35T. The steel truss is made of Q355B steel.

FIG. 1 Structure diagram of the gymnasium roof

2 construction technical difficulties and countermeasures

Due to the large span (50.7m) and weight (about 35t) of the truss, the lifting capacity is larger than that of the tower crane within the coverage area of the site, and the tower crane laid on the site is difficult to meet the lifting requirements of the whole truss, which brings great difficulty to the installation.

2.1 Complex Structure

(1)Because the steel truss assembly needs to occupy two floors of the concrete construction site, and the construction period is long (it needs to assemble the truss on the second floor, other types of construction can not be carried out on the same working face).

(2)Steel truss roof assembly in the field needs to occupy two floors of the concrete construction site, and the weight of the truss is large, so it is not suitable for steel truss assembly and hoisting in the field. Therefore, the installation of the truss adopts the overall assembly of the off-site ground and adopts the overall lifting method of 2 300T automobile cranes.

(3)The length of truss members is too long (the longest member is 59m) to be transported as a whole, so the steel structure factory will process and manufacture the longest member in sections according to 25m and assemble it on the ground as a whole after assembling and hoisting it as a whole.

2.2 It is difficult to lift the steel truss

The roof long-span truss (43~59m) has 10 sections. Due to its location in the center of the structure, the truss has a large span and a weight of about 35t, so it is difficult for the onsite tower cranes to meet the lifting requirements of the whole section of the truss, which brings great difficulty to the installation. Therefore, the large-span trusses and some overweight trusses were assembled on the ground as a whole and then lifted by 300T truck cranes. The rest trusses were combined by 50T truck cranes and hoisted by tower cranes.

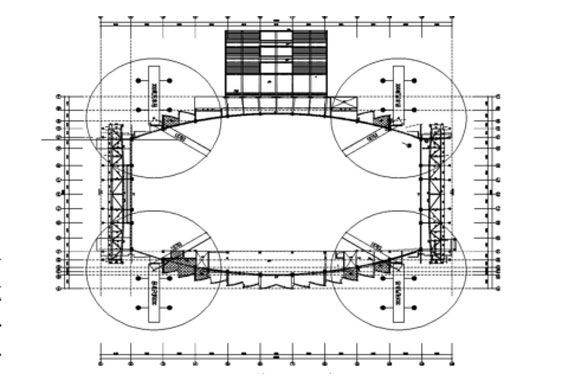

3. Steel truss installation

The columns corresponding to the large span truss of the roof are installed, and the large span trusses on both sides of the stadium are constructed in parallel. The construction sequence is to lift the middle part of the large span truss first and then lift the north and south sides successively. After the installation of the large-span truss is completed, the two sides are constructed in parallel to carry out the installation of the secondary truss. As the span is 34m(weight is 16T), two 300T cranes are used for hoisting, and the cranes stand between 3 and 4 axes (as shown in Figure 2). At this time, one crane can lift 23.8T weight, and fully meeting the lifting requirements. Because the truss has six concrete columns connected to it, there is no need to add a wind rope, and the second truss member can be lifted after the position of the truss is corrected. The hoisting point of the steel truss is selected at the position of the first and second straight belly rod at the upper chord of both ends, and the φ 30mm steel wire rope hoisting can meet the hoisting requirements.

FIG. 4 Schematic diagram of hoisting plane

4. Welding of steel truss

The main steel member material of the project is Q355B, and the maximum site butt plate thickness is 30mm. The welding method is manual arc welding and CO2 gas-shielded welding. The truss joints are relatively complex, and the welding workload is large. According to the type of welding interface, the performance of the base material, and technical requirements, the welding of the steel column on-site mainly adopts semi-automatic CO2 gas-shielded welding (GMAW). The steel beam adopts semi-automatic CO2 gas shielded welding (GMAW) and manual electric arc welding (SMAW); SMAW truss welding is used for the parts with a small amount of welding and relatively scattered position. When the whole truss is installed and calibrated, the principle of welding from bottom to top and from middle to sides is adopted. The overall sequence of steel beam welding is that the frame structure of this layer is installed from the middle to both sides in turn. For h-shaped beam welding, the lower wing plate should be welded first, and then the upper wing plate. Weld one end of the beam first, and then weld the other end after the weld is cooled to normal temperature. Both ends of the same steel beam shall not be welded simultaneously, and the welding sequence at both ends shall be the same. In order to make the heat source distribution around the weld bead uniform and reasonable, preheating measures must be taken before welding. The heating area of preheating is on both sides of the welding groove, and the height and width are more than 2 times of the thickness of the welding place, and >100mm. After welding, heat preservation, after welding, cover thick asbestos cloth for heat preservation, and seal the air circulation area. When welding thick plate, the interlayer temperature between welds should always be controlled above the lowest preheating temperature, below 250℃, and each welding joint should be welded at one time. 100% check the appearance quality of the weld, strictly control the quality defects of the weld according to the grade of the weld, and repair the weld slag, root shrinkage, arc abrasion, porosity, and other quality defects after finding out the cause, repair the same part shall not exceed 2 times.

About Us

About Us 2022-11-11

2022-11-11