High-performance materials expand the performance boundary of space frame structure.

High-strength steel: The application of high-strength steel enables the space frame structure to withstand greater loads, and at the same time reduces the cross-section size of the members, which improves the space utilization rate while increasing the span and height of the structure. For example, in the space frame structure of some large stadiums, the use of high-strength steel can realize a large span space with a single span of more than 100 meters, providing the audience with a broader view and a more comfortable spatial experience.

Aluminum alloy material: Aluminum alloy has the advantages of light weight, corrosion resistance, etc., which can significantly reduce the self-weight of the space frame structure. In some occasions with higher weight requirements, such as the maintenance hangar space frame structure in the aerospace field, the aluminum alloy space frame structure meets the requirements of structural strength, and facilitates the installation and maintenance, and at the same time, reduces the load bearing requirements of the foundation.

Carbon fiber composites: Carbon fiber composites have ultra-high strength and modulus, as well as good corrosion resistance and fatigue properties. Applied to the key parts of the space frame structure, such as node connections or tensile members, it can effectively improve the overall performance and reliability of the structure. Although its high cost limits its large-scale application, it has begun to make its mark in some special projects that require high structural performance, such as the reinforcement and repair of bridges or the local strengthening of high-end buildings.

Advanced manufacturing technology to improve the quality and efficiency of space frame structure.

3D printing technology: 3D printing technology can directly manufacture complex space frame structure components according to the design model, realizing the rapid transformation from digital model to solid components. This not only shortens the manufacturing cycle, but also creates complex shapes and structures that are difficult to realize with traditional processes, and improves the mechanical properties and aesthetics of the structure. For example, in some architectural vignettes or creative architectural space frame structure, 3D printing technology can create unique nodes and components, adding a unique artistic charm to the building.

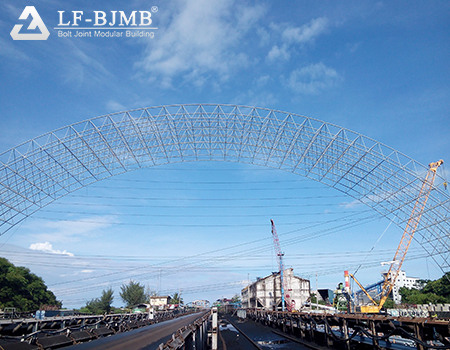

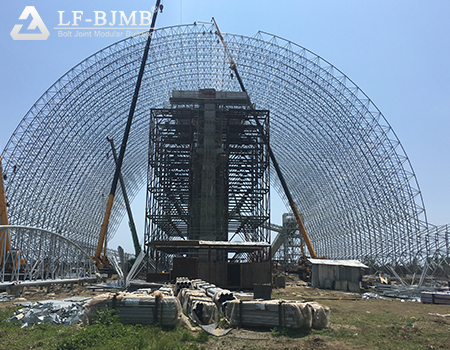

Prefabricated assembly technology: Prefabricated assembly space frame structure will most of the components in the factory prefabricated production, and then transported to the site for rapid assembly. This way greatly reduces the workload and time of on-site construction, improves the construction efficiency, and also ensures the quality and precision of the components. Like the space frame roofing system in some assembly buildings, through prefabricated assembly technology, it can be installed in a short time, reducing the impact on the surrounding environment of the construction site.

Digital technology optimizes the design and monitoring of space frame structure.

BIM technology: BIM technology provides a three-dimensional visualized information platform for the design, construction and operation management of space frame structure. In the design stage, designers can carry out virtual construction and collision checking through BIM models, timely discover and solve problems in the design, optimize the structural layout and connection methods, and improve the design quality. In the construction phase, construction personnel can carry out accurate construction simulation and progress control based on the BIM model to ensure the smooth progress of construction. In the operation phase, managers can use the information in the BIM model to conduct real-time monitoring and maintenance management of the space frame structure to extend the service life of the structure.

Interspace of Things and Sensor Technology: By installing various sensors, such as strain gauges, displacement sensors, temperature sensors, etc., on the space frame structure, and realizing real-time data collection and transmission with the help of Interspace of Things technology, the stress state, deformation and environmental factors of the space frame structure can be monitored for a long time. Based on these data, engineers can understand the health condition of the structure in time, predict potential safety hazards, and take corresponding measures for maintenance and repair to ensure the safe and reliable operation of the structure.

New connection technology to enhance the stability of the space frame structure.

High-strength bolt connection technology: High-strength bolt connection has the advantages of convenient construction, reliable connection, and can withstand large tensile force and shear force, etc., and has been widely used in the space frame structure. The new high-strength bolts are constantly improved in material properties and manufacturing process, which further improves the strength and reliability of the connection, and at the same time simplifies the construction process and speeds up the construction progress.

Prestressing connection technology: Prestressing connection technology can effectively improve the stiffness and bearing capacity of the node and reduce the deformation of the structure by applying prestressing in the connection part. In some large-scale space frame structures, such as exhibition halls, terminals, etc., pre-stressing connection technology can make the structure more stable, and at the same time, it can also reduce the amount of steel used in the structure and save costs.

Welding robot technology: the application of welding robots improves the quality and efficiency of the welding of space frame structures, and ensures the consistency and stability of the welded joints. Welding robots can accurately control the welding parameters, reduce the influence of human factors, improve the welding quality, and also can work under the harsh environmental conditions to improve the safety of construction.

Green energy-saving technology to promote the sustainable development of space frame structure.

Solar photovoltaic technology: Combining solar photovoltaic panels with the space frame structure can realize the energy self-sufficiency of the building. Installing solar photovoltaic panels on the roof of the space frame frame does not affect the normal use function of the structure, but also utilizes solar power generation to provide clean energy for the building, reduces dependence on traditional energy sources, and lowers carbon emissions.

Heat preservation and insulation technology: The use of highly efficient heat preservation and insulation materials, such as new types of heat preservation panels and heat insulation coatings, in the enclosure structure of the space frame structure can effectively reduce the energy consumption of the building and improve the efficiency of energy utilization. At the same time, these heat preservation and insulation materials also help to improve indoor thermal comfort, reduce the frequency of air conditioning and heating, and realize the goal of energy saving and emission reduction.

About Us

About Us 2025-04-28

2025-04-28