Prefab airplane hangar steel structure arch truss roof.

On July 1, 1997, the prestressed steel arch structure project of the hangar built by Australian STARCH INTERNATIONAL at Macau International Airport was lifted. After the overall production and assembly of the steel structure roof, the prestressed tensioning technology is used to make the entire roof structure arched. Because of its lightweight and fast construction speed, it has attracted people’s attention and interest.

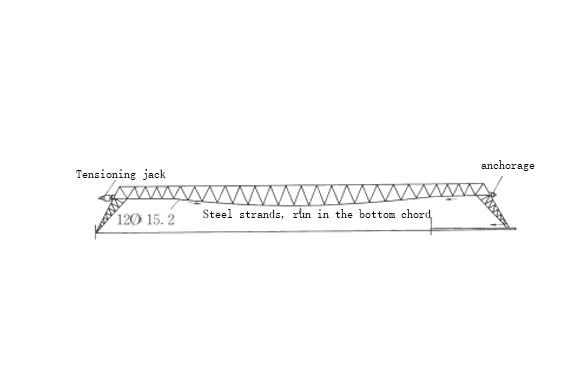

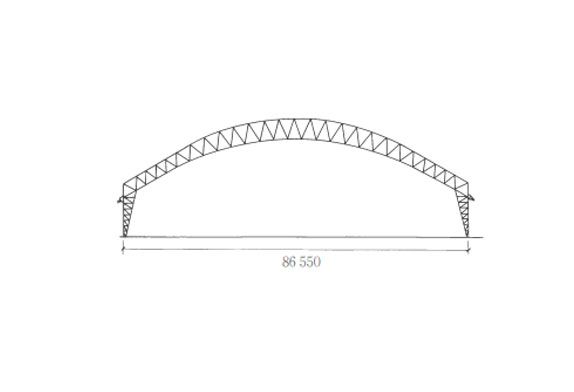

The steel arch truss aircraft hangar has a span of 86.55m, a column spacing of 8.00m and 6.18m, a total of 9 bays, a total length of 70.30m, and 10F. The roof panel is a lightweight pre-formed sheet metal roof. The upper chord of the arch is a square tube, the lower chord is formed by welding a combination of a square tube and a round tube, and the web bar and the supporting system are round tubes. The entire structure includes trusses, support systems, roof panels, plumbing, electrical lighting, etc. All of them can be assembled at one time, and then the steel strands are passed through the lower chord and the tensioning equipment is installed. Figure 1 shows the assembled steel arch airplane hangar roof before prestressing. Since a retractable steel sleeve is arranged in the middle of each lower chord, the lower chord is shortened during the tensioning process, and the web can be rotated at the connection between the web and the upper and lower chords. It is gradually formed into a steel structure arched roof. One end of the column foot is slid into place, the column foot is fixed, the anchorage is locked, the lower chord is pressure-filled with grout, and the arched roof is completed, as shown in Figure 2.

Fig. 1 The situation before prestressing after the steel arch hangar roof is assembled

Fig. 2 The situation after the steel arch truss hangar roof is prestressed

The characteristics of the prestressed steel arch structure are (1) it can be integrally stretched continuously and synchronously; (2) the lower chord of the arch frame is a retractable member; (3) the nodes of the web members of the arch frame are rotatable nodes. This new technology originated in Australia and has been extended to the United States, Canada, the United Kingdom, Japan, Taiwan and other places. In addition to hangars, there are construction examples in roofing projects such as large-span bulk warehouses, gymnasiums, commercial markets, and exhibition halls.

About Us

About Us 2022-04-01

2022-04-01