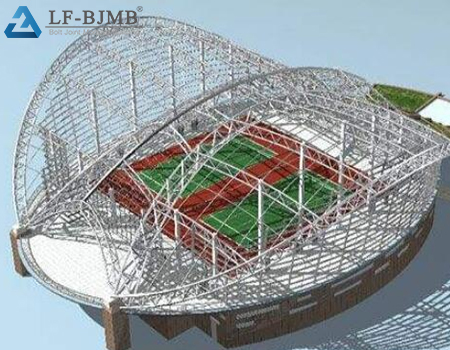

Stadiums are generally used for sports competitions, physical exercise, or for holding concerts and performances. Stadiums can typically be classified into three categories by scale: large, medium, and small. Inside stadiums, it is common to see that the roof or surrounding areas are supported by steel space frame structures. With the rapid development of China’s economy, large-span space frame structures have been increasingly applied in construction projects. As a new type of steel structure, the space frame features rational force distribution, light overall weight, low cost, and a lively, novel appearance. At the same time, it offers good stability and safety.

The emergence of space frame structure has attracted significant attention due to their unique and artistic appearance, highlighting the creative capabilities of human architectural design. Space frames meet people’s requirements for living and spatial environments by offering larger covered spaces. As a result, they are being adopted more widely in steel structure construction projects, especially in large cultural and sports centers. Representative buildings in China include the Shanghai Stadium, the Shanghai Swimming Center, and the Liaoning Stadium, all of which exhibit distinctive architectural character.

The installation method of space frame structures should be determined comprehensively according to the structural shape and load-bearing configuration of the frame, while also satisfying the requirements of quality, safety, progress, and economic efficiency. Local construction techniques and conditions should also be considered. The specific installation methods for space frames include: high-altitude assembly, strip or block installation, high-altitude sliding, overall hoisting, overall lifting, and overall jacking. Regardless of which installation method is selected, a trial assembly and test installation must be conducted before formal construction to ensure accuracy and compliance with design requirements before proceeding with full-scale execution.

1. High-Altitude Assembly Method

This refers to assembling small units or loose components (individual rods and nodes) directly at their designed positions in the air. It is suitable for various types of space frames with bolted joints, especially when lifting operations are difficult. The key aspects of this method are determining a reasonable assembly sequence and precisely controlling elevation and axis positioning.

2. Strip or Block Installation Method

This involves dividing the space frame into strip- or block-shaped units, which are hoisted to their designed positions in the air using lifting equipment and then assembled into a complete structure. It is suitable for space frames in which stiffness and load-bearing capacity do not change significantly after segmentation, such as double-directional orthogonal square pyramids and open square pyramids. This method is conducive to improving construction quality and can save a significant amount of assembly scaffolding.

3. High-Altitude Sliding Method

This method refers to sliding preassembled strip units of the space frame along tracks that are installed in advance, moving each unit into position where they are then connected to form the complete structure. It is suitable for space frames such as orthogonal square pyramids, open square pyramids, and double-directional orthogonal square pyramids. During the sliding process, each sliding unit must maintain geometric stability.

4. Overall Hoisting Method

This method involves assembling the entire space frame on the ground and then using lifting equipment to hoist it into place. Welding and other work are completed at ground level, which ensures better construction quality. This method is applicable to all types of space frames, and during hoisting, the frame can be moved horizontally or rotated into position in the air.

5. Overall Lifting Method

This method involves installing lifting equipment on the structural columns to raise the fully assembled space frame from the ground into its final position. The lifting operation can be performed either after the column construction or concurrently during column slip-form construction. It is suitable for space frames with peripheral or multi-point supports. Equipment such as lifting machines or hydraulic jacks can be used for construction.

6. Overall Jacking Method

This method involves assembling the entire space frame at ground level directly beneath its final design position and then using jacks to raise it to the designated height. It is suitable for space frames with fewer support points and multi-point support configurations.

About Us

About Us 2025-06-30

2025-06-30