Integral Sliding Method: Intelligent Coordination for Efficient Installation

(1) Application Scope and Prerequisites

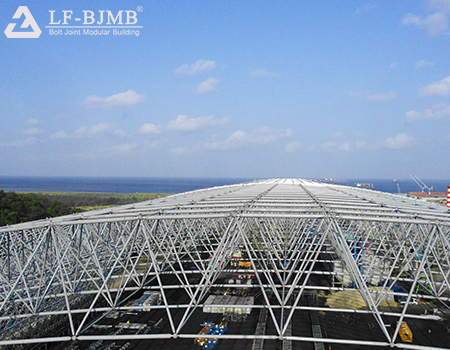

The integral sliding method is applicable to large-span, large-area space frame structures, such as large stadiums and exhibition centers. When the construction site conditions allow sufficient space for frame assembly and the setup of sliding tracks, and there is a tight construction schedule, this method is particularly suitable. Taking a large stadium as an example, it has a large-area space frame roof and an open surrounding site, which provides favorable conditions for the implementation of the integral sliding method.

(2) In-depth Analysis of Construction Steps

Space Frame Segmentation: Based on the characteristics of the space frame structure and on-site construction conditions, the frame is reasonably divided into several sliding units. Segmentation should consider structural forces, unit weight and size to ensure safety and stability during sliding. Reliable connections are used between units to facilitate later assembly.

Track Installation: Sliding tracks are laid below the installation position of the frame in the sliding direction. Tracks should have sufficient strength and rigidity to bear the load during sliding. Appropriate track materials, such as steel rails or I-beams, are selected to ensure a smooth surface and reduce resistance. Track installation accuracy must be precisely controlled to ensure alignment and elevation meet design requirements. Limiters are installed on both sides of the track to prevent deviation during sliding.

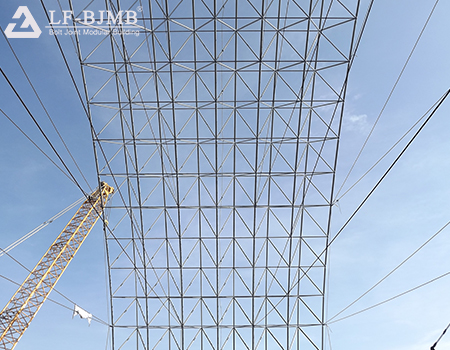

Synchronous Sliding: Sliding equipment such as trolleys or jacks is installed beneath each sliding unit. Using a computer-controlled synchronization system, the operating speed and stroke of each device are precisely controlled to ensure smooth and synchronized movement of all units. During the sliding process, real-time monitoring of displacement and deformation is conducted, and parameters are adjusted promptly to ensure construction safety and quality.

Positioning and Fixation: After the frame slides to the designed position, it is lifted to the design elevation using jacks or other lifting equipment for accurate adjustment and positioning. Welding, bolt connections, etc., are used to firmly connect the frame to the substructure, completing the fixation. All connection points are thoroughly inspected to ensure they meet design requirements.

(3) Highlighted Advantages

Fast Construction Speed: Frame assembly can be carried out on the ground simultaneously with other construction procedures, greatly shortening the construction period. For instance, in an exhibition center project, the integral sliding method reduced the construction period by several months compared to traditional installation methods.

Easier Quality Control: The ground environment facilitates operations and inspections, effectively ensuring frame assembly quality. The synchronous sliding system precisely controls displacement and deformation, ensuring installation accuracy.

High Safety Performance: Reduces high-altitude operations, lowering risks for construction workers. Ground assembly and sliding allow for more comprehensive safety measures.

(4) Potential Issues and Solutions

High Precision Requirements for Track Installation: Track installation accuracy directly affects smooth frame sliding. Strengthen measurement and monitoring during installation using high-precision instruments to ensure accuracy. Conduct comprehensive inspections and acceptance after installation.

Significant Impact on Surrounding Environment: Sliding may generate considerable noise and vibration, affecting nearby environments and buildings. Schedule construction reasonably to avoid disturbing residents during rest hours. Take effective noise and vibration reduction measures, such as placing rubber pads under the tracks.

Comparison Between the Two Methods: A Choice Based on Advantages and Disadvantages

(1) Economic Cost Comparison

In terms of material cost, the high-altitude assembly method involves more transportation of rods and nodes, and requires the purchase of large quantities of temporary support materials like scaffolding pipes and fasteners, leading to higher material costs. In contrast, the integral sliding method allows for centralized material transport and ground assembly, avoiding the need for extensive temporary supports and thus lowering material costs.

Regarding equipment cost, the high-altitude method generally requires only small lifting equipment such as winches and hoists, resulting in low rental costs. The integral sliding method, however, needs large lifting equipment for hoisting the frame segments, as well as sliding tracks and devices, leading to high equipment purchase and rental costs.

As for labor costs, the high-altitude method is slower and requires more workers over a longer period, thus incurring higher labor costs. The integral sliding method is faster, needs fewer workers, and has a shorter timeline, resulting in lower labor costs.

In conclusion, the integral sliding method offers significant cost advantages for large-scale projects due to its shorter duration and efficient use of materials and equipment, despite the higher initial equipment investment. The high-altitude method is more suitable for small or space-limited projects with lower upfront costs but higher long-term expenses.

About Us

About Us 2025-06-20

2025-06-20