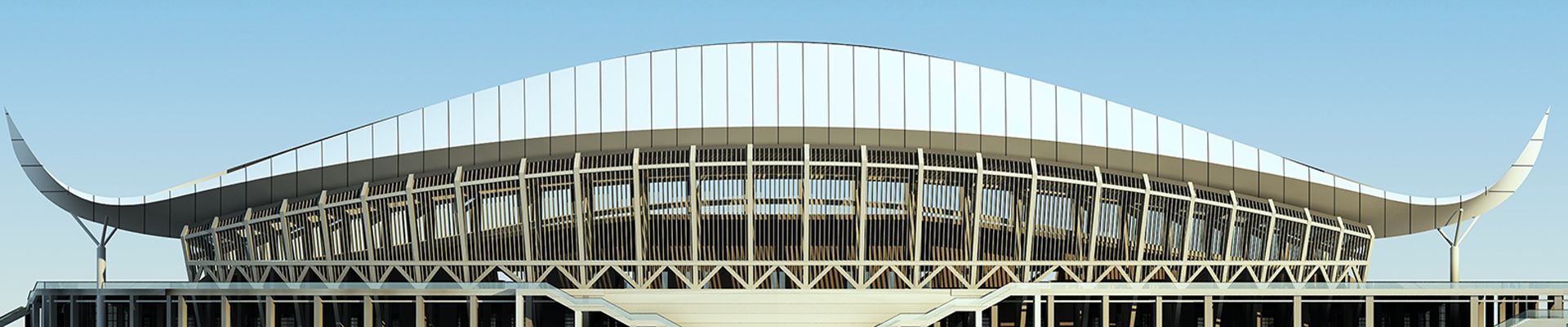

Guiyang Longdongbao Airport Terminal 2

The Guiyang Longdongbao International Airport Terminal project is a key project of the country’s western development, with a total construction area of 110,000 ㎡.

(1) The steel structure airport includes the main terminal building in Area B, the corridor in Area C, the corridor in Area D and the corridor in Area E.

(2) The main structure of the first underground floor and the first floor above ground is a cast-in-place concrete frame structure.

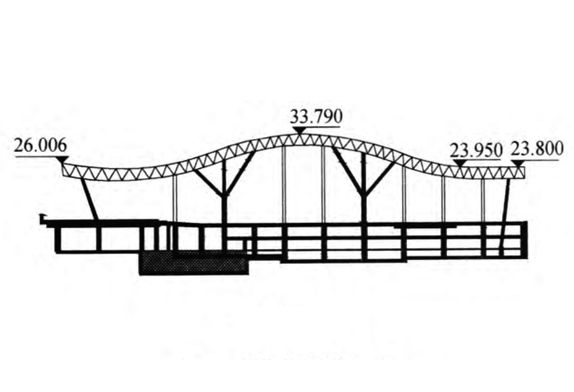

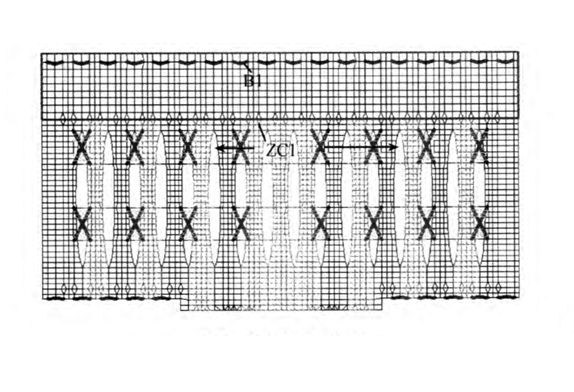

(3) The main structure of the main airport terminal building in Area B on the 2nd floor above ground is a steel structure quadtree-shaped column and a large-span curved space frame roof structure on top of the Y-shaped column;

(4) The main structure of the corridors in C, D, and E areas is a roof structure with a square pyramid double-layer plane space frame placed on top of conventional steel structure columns.(5)The space-frame roof of the terminal building adopts a high-altitude bulk method combining sliding scaffolding and partial full-room scaffolding.

Product Category

Product Category

Chat with us

Chat with us

Leave a message

Leave a message