The forklift workshop covers an area of 70,000 m 2 , with a length of 327m and a width of 278m. The roof is a 48m×12m steel welded space frame. The drainage method is organized internal drainage and part of the external gutter drainage. Due to the large single area and large span of the roof, and the steel space frame roof structure , there are many cranes running in the factory building , and the vibration is relatively large , so that the roof is in the process of elastic changes , and the design and construction of the roof waterproofing project are difficult. To this end, multiple lines of defense have been adopted , new waterproof materials have been selected , and a process design and strict construction plan have been formulated .Xuzhou LF Space Frame Manufacturing Co., Ltd. will introduce the waterproof design of the factory building in detail below.

1 waterproof process design

- Concrete roof slab seam treatment: Pour fine stone concrete → embedded PVC ointment → PVC modified coal tar sand surface membrane strip seam.

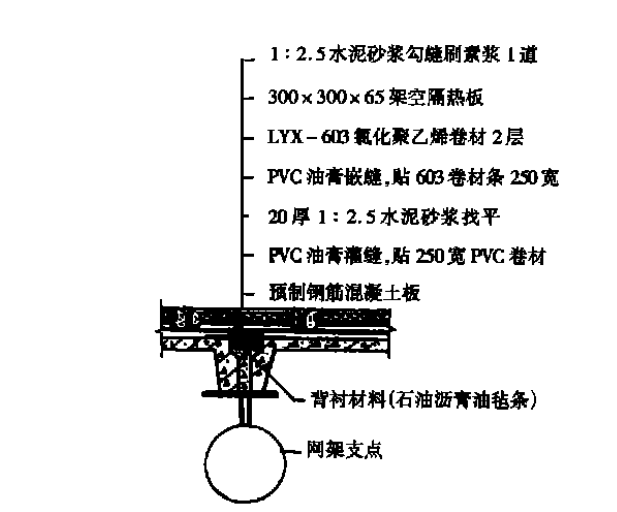

- Cement mortar leveling layer: cement perlite slope finding in the gutter → cement slurry brushing → 20mm thick cement mortar leveling layer → PVC ointment embedded in the joints of the warehouse → chlorinated polyethylene rubber waterproof membrane (603 membrane) strip seams (Figure 1).

Figure 1 schematic diagram of roof nodes

- Waterproof layer: 1.2mm thick 603 coil joint strengthening pretreatment → 1.2mm thick 603 coil paving → 1.5mm 603 coil paving.

- Insulation layer: Cement-wrapped perlite overhead insulation board paving.

- Protective layer (part without heat insulation layer): apply AAS reflective heat insulation paint.

2 Waterproof construction

2.1 Base construction

Pour and pound the fine stone concrete in the roof slab seam to a thickness of 6cm . After drying, use a wire brush to remove the floating dust on both sides of the slab seam , spread linoleum strips on the fine stone concrete , and fill 4cm thick PVC ointment in two times , and then place on both sides of the seam. Scrape PVC ointment on the board surface and lay PVC modified coal tar sand surface waterproof membrane strips with a width of 25cm , and use two oils and one cloth (PVC ointment, glass fiber cloth) to pre-strengthen the inner corner joints that are higher than the roof . The gutter in the roof is designed with 0.4% structural slope finding , and then cement perlite is used as 0.6% material slope finding. After brushing the cement paste mixed with 107 glue on the roof panel , a 2cm thick cement mortar leveling layer is applied , and the original Leave a sub-bin seam at the relative position of the board seam . After maintenance and drying, fill PVC ointment in the sub-bin seam , and paste a 20cm-wide 603 coil strip on one side of the seam . Uneven , no sand running phenomenon , calendering again , and timely maintenance.

2.2 Waterproof layer construction

First, do 1.2mm thick 603 coiled material strip pre-strengthening treatment on the gutter, parapet, inner corner of the root of the air inlet and exhaust, daylighting window, and inner corner of the side of the air building, and then use 1.2mm thick 603 coiled material Carry out strip sticking and paving , and then cover the surface layer with a layer of 1.5mm thick 603 coiled material. Coiled material paving requires that the base layer be dry and flat , without floating dust , and the paving should be smooth , without bubbling, wrinkling, warping and opening , and the sealing should be tight. The overlapping seams of the upper and lower layers of coils should be staggered by more than 1/3 , and the width of the overlapping edges is: the long side ≥ 8cm , and the short side ≥ 10cm. The coiled material is sealed with PVC ointment after being nailed with iron strips at the base without grooves.

2.3 Heat insulation layer and protective layer method

On the waterproof layer of the roof, use cement mortar to pave the prefabricated perlite prefabricated heat insulation board with cement . Apply a full layer of paint to close the pores on the surface of the insulation board and reduce water absorption. Apply a layer of AAS reflective and heat-insulating white paint as a protective layer on the waterproof surface of gutters, parapets, etc. that are not covered with heat insulation boards. It has been one year since the completion of this project , and the 80,000 m 2 roof waterproofing layer has no leakage point so far.

About Us

About Us 2023-06-09

2023-06-09