The space frame structure has the characteristics of a large span and good integrity, so it has been widely used in large-span workshops, especially in airport hangars. During the construction of the large-span prefab hangar space frame, the speed and accuracy of the space frame installation have become an important part of restricting the construction progress. For a long time, the installation of the long-span hangar space frame is mostly high-altitude hoisting. How to install it in a convenient, fast, time-saving, and labor-saving way The space frame is particularly important in the current development of the construction industry. The overall lifting technology of the space frame is adopted, so that most of the space frame can be assembled on the ground, which reduces the workload of the space frame assembly, realizes the goal of high efficiency and high quality of space frame installation, and has great promotion prospects.

1 Airport construction process

Measuring and positioning → assembling the space frame on-site → assembling the jacking equipment → laying steel plates → checking the equipment → test jacking 20cm and standing for 12 hours → testing the foundation and main structure → officially lifting the space frame → extending and assembling the space frame → repeating jacking and extension assembly space frame → jack up the space frame to the design elevation of the support → connect with the space frame support → unload the jacking equipment.

2 Operation points

2.1 space frame measurement

(1) Before construction, carefully review the drawings, determine the relative positioning relationship between the plane and elevation of the building, and establish a plane and elevation control network. Before establishing a control network, the elevation provided by the project, the reference point of the control network, The embedded size, flatness, and elevation of the embedded parts shall be re-measured.

(2) According to the control point and the main axis point (the coordinates are known), use the method of point measurement and set up four control points to form a rectangle on the surrounding open space of the construction operation area, and then re-measure the control points to obtain four control points. Accurate coordinates of the points, establish an accurate space frame and use a steel ruler to measure the vertical distance along the concrete column or measuring platform (at least 3 points are guided upward at the same time). Because the roof is a space frame structure, three-dimensional space coordinates are used to determine The location of the node.

(3) Check the size measurement of the space frame assembly, the steps are as follows. Step 1: Bolt welding positioning line (after the temporary support is installed, the center line of the middle bolt ball and the upper ball is staked to the ground, as the control line for assembling the middle and upper bolt balls).

Step 2: Check the diagonal dimension of the bolted ball.

Step 3: Assemble the middle ball, use the ground control line to check the position of the middle ball, and use the steel ruler to check the height h of the middle ball.

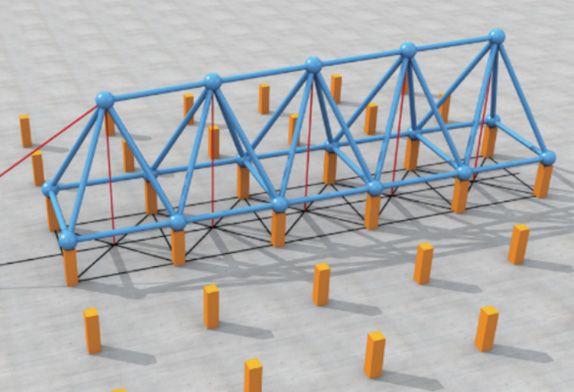

Step 4: Use the same method to assemble the bolt welding ball and use the ground control line to check the center line of the ball, and use the steel ruler to check the height of the bolt ball. As shown in Figure 1.

FIG. 1 Assembling bolt welding balls

2.2 Space frame assembly

(1) Strictly inspect the balls and rods, and check their processing dimensions if necessary; project the nodes of the steel space frame onto the site, and set up temporary supports according to the height difference of each node.

(2) Assemble the space frame on the site, the space frame extends from the middle to the two sides space frame by space frame, the first chord, then the chord, the lower chord ball must be on its projection line; install the lower chord plane space frame, use the theodolite and tape measure to coordinate the alignment. Make sure the axis and the center line of the top of the column, use a level to align the elevation, install the lower string ball and rod between the first spans to form a longitudinal plane space frame, arrange the leveling support points, and ensure the equality of the lower string ball. The bottom of the slope should be found on the temporary support point.

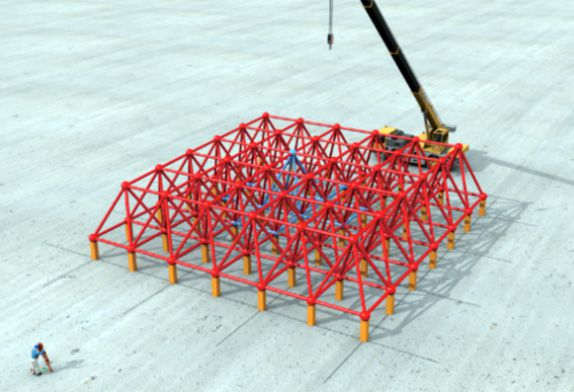

(3) Use a high-precision total station to accurately measure and position the nodes of the space frame. After the assembly in the central area is completed, the mutual positioning between the ball and the rod is used to gradually expand and assemble. Each unit space frame needs to be measured once. During the installation of the steel mesh frame, the assembly error of the steel mesh frame must be measured and controlled at all times. space frame assembling and laying out → Masonry positioning steel pipe → assembling the first layer of welding balls → assembling the first layer of chords → assembling the second layer of balls and the first layer of web rods → gradually expanding outward using the mutual positioning between the balls and the rods Assemble, assemble the two-layer ball, and the rod is connected to a fixed position, as shown in Figure 2.

FIG. 2 Space frame expansion splicing

2.3 Space frame jacking up

(1) Mark the jacking coordinates on the adjacent pillars for jacking measurement and control. Before the jacking frame is installed, the support foundation must be checked and accepted to ensure that the position and elevation deviation of each support point are within the allowable range. Inside.

(2) Start the pump station to make the jack piston rise one stroke synchronously. Each standard section is fixed with two pieces of jacking frame and angle iron connected with Φ16mm×45mm high-strength bolts to form a lattice, each lattice (length 1.3m, width 1.2m, height 1m), the top drag and bottom drag and the oil cylinder are connected by Φ20mm×150mm high-strength bolts.

(3) When the jacking height meets the next space frame assembly, the jacking is suspended, and the assembled grid is extended outward. When assembling the jacking frame, it must be ensured that the verticality error between the center and the jacking point of the grid frame is within 5mm.

(5) During the official jacking, each stage of the jacking process can be advanced synchronously. During the jacking process, the monitoring data such as the stress, deformation, and jack stroke of the building should be monitored throughout; When the rope clamp is tightened, the cable should be tightened until there is a certain depth of the groove; after the reinforcement work is completed, check each link part one by one; set the elevation reference point, and put the reference point on each concrete column. Welded balls and lower chord balls with larger deflection and deformation of the grid frame are used to set observation points. Measure the elevation of each observation point before the grid frame is jacked up, and make a record. When the grid frame is lifted, measure the elevation of each observation point again; The height difference between the bottom observation point and the elevation datum point.

2.4 Space frame welding

(1) According to the requirements of the design drawings, comprehensively check and check the welding groove size, the reserved gap at the root, the groove form, and the welding position, and check the wrong side and plate thickness.

(2) Before welding, the oil, moisture, and oxide scale in the welding groove and on both sides of the groove should be cleaned with wire brushes, grinding wheels and other tools.

(3) The welding materials used for tack welding must be the same as the formal welding materials. Tack welding must be started after preheating before welding, and the preheating temperature should be higher than the formal welding temperature. The thickness of the welding seam of the tack welding should not exceed 2/3 of the thickness of the design weld, the length of the tack welding should not be less than 40mm, the spacing should be 300-600mm, and the arc crater should be filled. Same production.

(4) For full penetration welds with double-sided grooves, the roots should be cleaned on the reverse side of the weldment after 2 to 3 welding passes.

2.5 Space frame unloading and lifting removal

(1) Before unloading the grid, check the axis deviation of the space frame and the installation and discharge of the support.

(2) The unloading of the space frame in place adopts the synchronous descending method, according to the principle of “the overall synchronous descending in the same proportion”. That is, all the jacks fall synchronously, and each synchronous fall is set to 10mm until the lower string ball of the space frame is in full contact with the spherical fixed hinge support.

3 Benefit Analysis

The overall jacking method has a fast construction period, and the ground space frame installation improves the space frame installation construction efficiency and saves construction costs. The traditional crane installation method requires 5 days to install the 1000m² space frame, but using the innovative construction method of ground assembly and jacking into place, the 1000m² space frame installation only takes 3 days, so the 1000m2 grid frame installation construction period is shortened by 2d, and the overall construction period of the project is expected to be Can shorten 26d. Compared with the traditional crane installation, the large-span hangar space frame jacking method of the general airport requires fewer measures and reduces the construction cost due to the ground assembly method. According to the on-site statistics, each completed hangar saves about 5,000 yuan in facility costs. There are 4 hangars in this project, so it is expected to save 5,000 yuan × 4 = 20,000 yuan in loss costs. Since the installation of the hangar space frame is done on the ground, the amount of labor input is reduced. Compared with the traditional crane installation, the labor input is reduced by 3 per square kilometer, the labor cost per labor is 300 yuan/day, and the installation requires 3 The total area of the space frame is 13,000m2. After statistics, the total labor cost can reduce by 3×0.03×3×13=35,100 yuan.

About Us

About Us 2022-11-02

2022-11-02