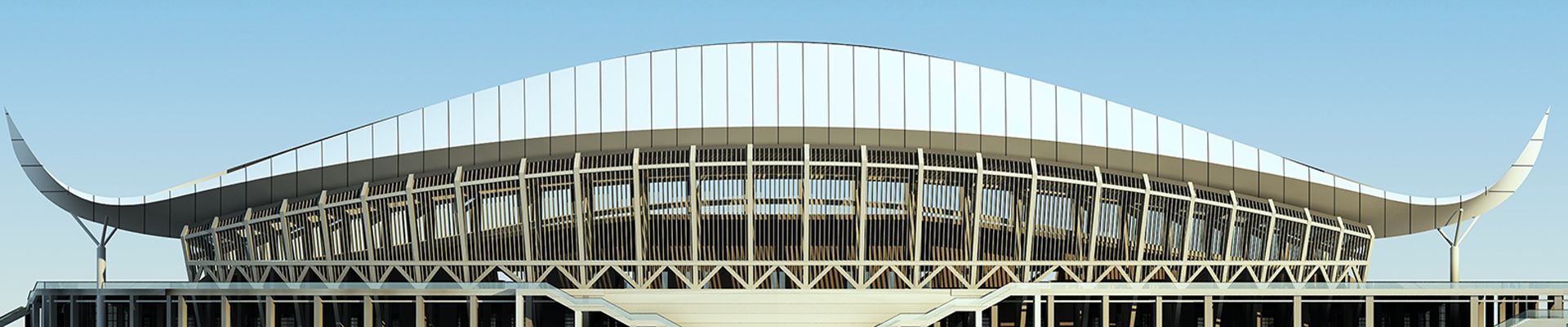

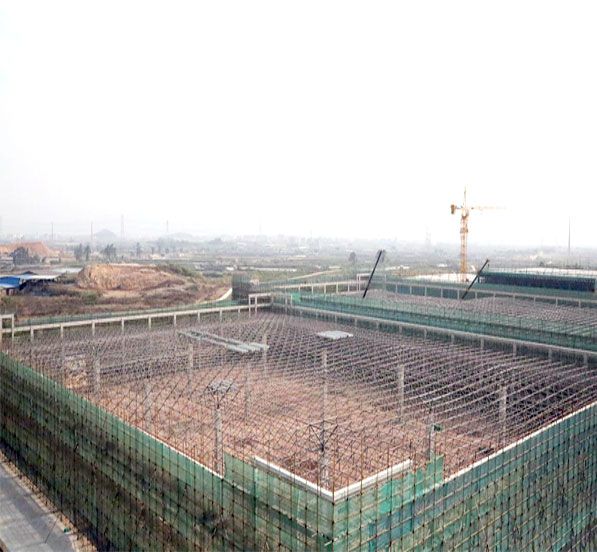

1. The total length of the steel warehouse from north to south is 432.48m, the total width from east to west is 144.48m, and the building area is 58777.19m². Mainly responsible for car interior, component assembly, chassis assembly, general assembly, vehicle performance testing, debugging, and repair work.

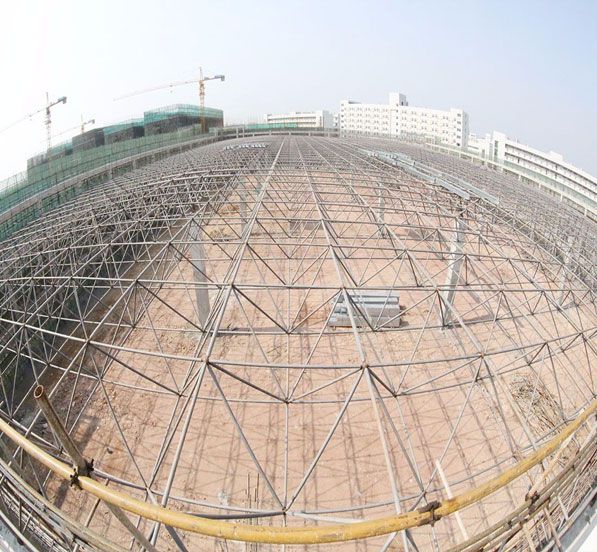

2. The roof of the steel warehouse building is a space frame structure, the plane axis is the 1~19 axis intersecting the A-G axis, the plane size is 432.48m x 144.48m, and the expansion joints are set at the 7th axis, and the 13th axis.

3. The warehouse steel structure design adopts the double-layer space frame structure of the square pyramid, and the joints are in the form of bolt balls (local welding balls). The maximum section of the welded hollow ball is WSR6022; the maximum section of the bolt ball is BS300. The support form is multi-point support on the lower chord layer, the maximum span of the support point is 32m, the support form is a flat plate pressure support, and the bottom elevation of the support is 9.600m.

Product Category

Product Category

Chat with us

Chat with us

Leave a message

Leave a message