1 Glass Dome Building Project Overview

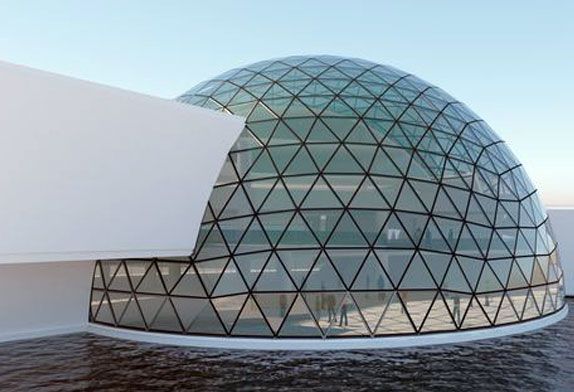

A museum project refers to the form of the Louvre in Paris. A hemispherical entrance is set in the sunken square. There are 4 floors underground, with a total construction area of 17,874m². The architectural effect is shown in Figure 1.

Figure 1 museum dome structure

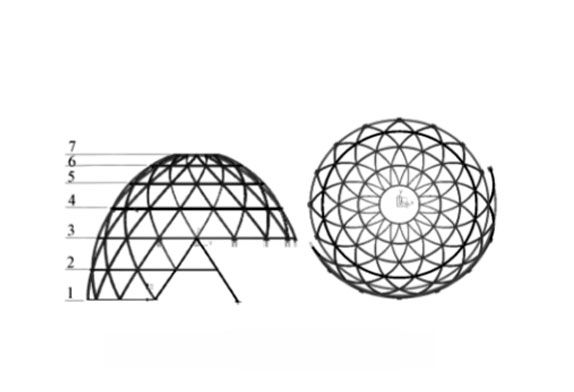

The glass roof dome structure of this project is hemispherical (see Figure 2), and it is composed of hot-rolled arc-shaped square tubes, the material is Q235B, and the main specifications are: RHS184 x84 x 8/RHS200 x 100 x 8/RHS250 x 150 x 101RHS200 x 100 x 12mm, maximum length 3 880mm, minimum length 780mm, maximum arc 25.07°, minimum arc 3.18°. The height of the dome structure is 13077mm, the ground elevation is -5.000m, the top surface elevation is 8.077m, there are 7 horizontal circles in the horizontal direction, the outer diameter of the bottom circle is 19500mm, the outer diameter of the top circle is 4135mm, and the net weight of the overall structure is 25.657t.

Figure 2 side view and top view of the dome structure

2 Analysis of characteristics and difficulties

According to the structural form of the glass dome roof, the technical difficulties of its pre-assembly can be summarized as follows.

1) The height of the dome structure is 13.077m, the outer diameter of the bottom ring is 19.5m, the outer diameter of the top ring is 4.135m, and there are more than 100 special-shaped components. How to formulate such a large-volume structure with a large number of special-shaped parts in an efficient pre-assembly process.

2) The dome structure adopts small-section arc-shaped hot-rolled square tubes with different lengths and radians. How to set a feasible and effective tire frame and control and adjust the precision of the tire frame to meet the precision requirements of the dome structure pre-assembly is a key issue. Pre-assembly is difficult.

3) The hot-rolled square tubes of the dome structure are all thin-walled components (8/10/12mm), and the auxiliary connectors are all thick plates (18-25mm). How to take effective measures to ensure the appearance quality of the weld and control the component’s Welding deformation.

3 Key points of pre-assembly technology

3.1 General idea of pre-assembly

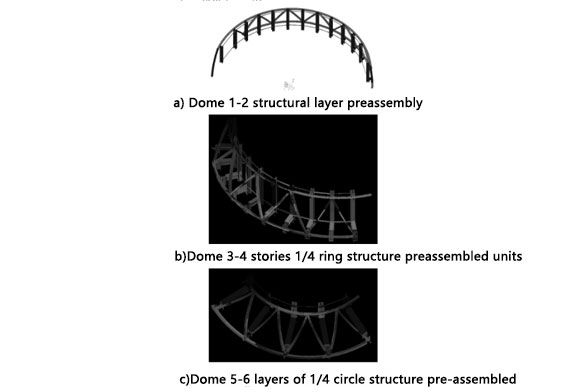

If the dome structure is pre-assembled as a whole, it will require a lot of space, and the amount of tire frame will be high, which is time-consuming and labor-intensive. In order to reduce the assembly strength and cost and improve the assembly efficiency, it is necessary to combine the symmetry and layering characteristics of the dome structure, and adopt layered pre-assembly, that is, 1~2 layers (horizontal circle), 3~4 layers (water, flat circle) And 5-6 layers (horizontal circle) a total of 3 tire frames are pre-assembled at the same time. The assembly sequence adopts the second pre-assembly: ① First, 1-2 layers, 3-4 layers, and 5-6 layers are pre-assembled at the same time, of which 1-2 layers are pre-assembled as a whole, and welded into 2 single pieces; 3~ The 4th and 5th to 6th layers are pre-assembled into 1/4 circles, and welded into 4 single pieces; ②Then, the 3rd to 4th layers of 4 single pieces are generally reborn to test the overall assembly effect of every single piece, and the specific assembly ideas As shown in Figure 3.

Figure 3 dome construction

About Us

About Us 2023-02-17

2023-02-17