The architectural image of the civic center is like a Dapeng spreading its wings (see Figure 1), with a grand spirit. The total construction area of the steel structure project is about 210,000 m², the steel roof structure has an area of 91,000 m², and has a total height of about 80m. 12 and 15 layers. The 12th floor is a circular tower with a diameter of 36m, and the 15th floor is a rectangular tower with a diameter of 36X45m.

Figure 1 steel roof structure design of the civic center

The large span steel roof structure of the civic center is supported by tree-shaped steel columns and two towers and spreads its wings over the comprehensive building complex of the civic center. The prefab steel roof is 486m long, the width is reduced from 154m at both ends to 120m in the middle, and the thickness between the centerlines of the upper and lower curved surfaces is changed from 2.25m to 9.00m. The steel structure roof is divided into three independent parts, two symmetrical wings, and a middle.

The two symmetrical wings in the east and west are double-bolt ball space frame structures, which are respectively supported on 17 tree-like supports on the roofs of the buildings in the east and west areas. The horizontal space frame spacing is 3m, and the rods are made of round steel pipes. The central part of the roof consists of the round tower, the main truss around the square tower and the space frame between the main trusses and the main truss and the tree-like supports at both ends to form a spatial structure system. The main truss adopts a welded box section, the space frame adopts three-layer welded hollow spherical nodes, the horizontal spacing of the space frame is 6m, and the rods are made of round steel pipes. The connection between the space frame and the main truss adopts the connection of ribbed hemispherical nodes.

2. Steel roof structure installation plan

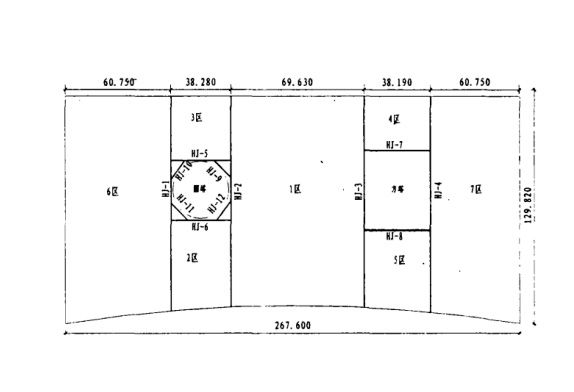

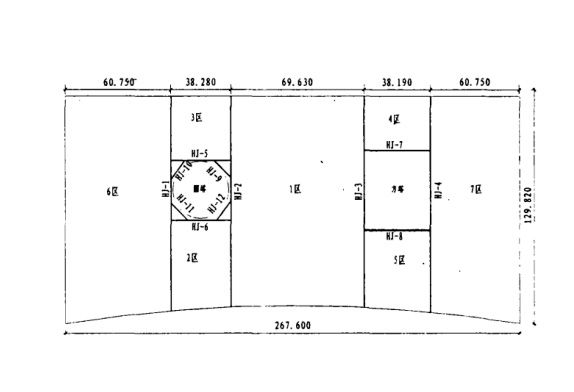

Due to the large steel roof structure being divided into three independent parts, the east, and west wings are bolted ball space frames, which are respectively supported on 17 sets of tree-like supports on the roof of the east and west buildings. The height of the space frames is about 10m from the roof. Although the space frame roof is complex in shape and difficult to process It is large, but the traditional full-house scaffolding method can be used for installation to meet the requirements. The central area of the big roof is about 270m long from east to west and 120m wide from north to south, and is composed of 12 giant trusses and space frames. The giant truss forms a whole around the round tower and the square tower and is suspended on the simple walls of the round tower and the square tower through 12 corbels. The space frame is divided into 7 districts by 12 large trusses (see Figure 2 for the distribution of trusses and space frames in the central area of the large roof), the space frames in zones 1 to 5 are connected to the truss through a hemisphere with a diameter of D600×20, and zones 6 and 7 are connected to the truss. One side of the space frame is connected to the truss, and the other side is transmitted to the lower concrete floor through 4 groups of tree supports. The maximum height difference of the lower chord of the curved beam truss HJ-2 of the round tower is 7.970m, and the elevation difference of the upper and lower chords is 15.96m; the maximum height difference of the lower chord of the curved beam truss HJ-3 of the square tower is 7.945m, and the elevation difference of the upper and lower chords is 15.96m. Among the 12 large trusses in the central area of the large roof, HJ1~HJ4 have a single weight of 290t and are three-layer curved beams with box-shaped sections, which are very difficult to process and install. The three-layer welded ball quadrangular pyramid space frame in the central area of the large steel structure roof is rare in China in terms of scale, processing, and installation difficulty. The maximum installation height of the space frame is 72.57m, the minimum installation height is 36,302m, the space frame size is 6000mm X 6000mm, the sag height is 4.355~8.490m, the welding ball specification is D280X10-D900X32, a total of 16 types, 2524 pieces, the rod is Φ114×4-Φ1000 ×20mm, there are 35 kinds of nearly 14,000 pieces and more than 6,000 serial numbers of different lengths.

The welding ball space frame in the central area has the following installation difficulties:

1. There are many kinds of balls and rods, and it is difficult to process and manage semicolons.

2. There are many super-large solder balls, which are difficult to process.

3. Because of the thick rod and small angle, there are more than 250 intersecting nodes, which brings great difficulty to the installation.

4. The space frame is tall, the scaffolding and space frame installation are carried out alternately, and the construction period is long.

5. The space frame is a three-dimensional curved surface, with multiple slopes, and each node has a different height, making it difficult to locate in three-dimensional space.

6. The space frame area is large and the installation height is large, which is difficult for lifting machinery to solve. If the method of high-altitude assembly is directly adopted, a 30,000-meter-long assembly tire frame needs to be erected, which is very expensive. On the one hand, high-altitude assembly increases vertical transportation, and on the other hand, the high-altitude operation has many potential safety hazards. The computer-controlled synchronous overall lifting and climbing technology of hydraulic jacks is a new technology developed in recent years. This new technology is widely used in the installation of large-scale steel structures and bridges. This technology reduces the assembly height, reduces high-altitude operations, and reduces deformation. quality. The computer can accurately control the stroke of each lifting point to achieve accuracy and stability.

Figure 2 Steel roof design truss, space frame distribution

7. Welding of steel structures. The material of the space frame ball and tube is Q235B and the field is manual arc welding. The electrode is E40 type, specification 3.2, Φ4.0, Φ5.0. The welding volume of the ball and pipe space frame is large, which is equivalent to the standard welding seam of 22966m. Welders shall weld in strict accordance with the welding sequence and process parameters specified in the welding process card. In principle, the welding sequence extends symmetrically from the center to the outside, and the free deformation capacity of each member node is left during welding to reduce stress concentration. The material of the truss is Q345B, which is manually arc welded on site. The electrode is E56 type, the specification is Φ4.0, Φ5.0.

8. Dealing with complex joints due to the peculiar shape of the large steel structure roof, the design of space frame and trusses is very complicated, especially the design of connecting joints breaks some of the conventional joint forms. The main design includes the following types of nodes: the connection between the upper and lower chords of the space frame and the upper and lower chords of the main truss is connected by a ribbed hemispherical node; the middle chord of the space frame is directly welded to the middle chord of the truss; the vertical intersection of the space frame and the two-bar truss Connected by 1/4 ball; when the hemisphere cannot be placed, the space frame member can be directly welded with the truss; when the rod intersects, it is required to retain the thick tube and cut the thin tube. During the node construction process, the construction unit worked out a detailed installation process according to the complexity of each node, avoiding hidden welds and ensuring reasonable structural stress.

Shenzhen Civic Center’s large steel roof structure design welded ball space frame was installed on August 15, 2001, the first overall upgrade was successfully completed on November 9, 2001, and the second overall upgrade was successfully completed on February 6, 2002. The installation was completed on March 21. So far, the steel structure project of the big roof of Shenzhen Civic Center has been completed. The successful realization of the installation and overall improvement of the steel space frame of the roof of the Shenzhen Municipal People’s Congress has far-reaching significance. It has brought the domestic steel structure installation technology and overall technology to a new level.

First: There are more than 1,400 cones in this space frame welded ball space frame. During the construction process, due to the better control of each link of the assembly, the assembly error is reduced and the assembly quality is improved, which not only ensures the quality of high-altitude installation but also reduces In the process of construction, improving work efficiency and reducing construction period played a role that cannot be ignored.

Second: super-large trusses roof and space frames are assembled on the low-altitude full scaffolding in situ, reducing the large number of tire frames, which not only speeds up the progress of the project but also ensures the assembly accuracy.

Third: The space frame assembly adopts the method of accumulating from the center to the surrounding without a liner and plug rod, which can ensure the installation accuracy, and can protect the groove, and prevent the steel pipe from being knocked.

In view of the overall situation of the steel structure roof design, we adopted low-altitude assembly, and the overall lifting and climbing technology was divided into pieces. In order to reduce the amount of high-altitude operations and reduce installation errors, the roof in the entire middle part is installed from the central axis to both sides. The assembly height of HJ2 and HJ3 is determined according to the elevation of the roof of the civil structure in the central area, and the assembly height of the truss determines the assembly height of the space frame in the first area. The lifting machinery is shown in Figure 3.

Figure 3 The layout of the space frame-mounted tower crane

Welding of steel structures material of the space frame ball and tube is Q235B, and the field manual arc welding. The electrode is E40 type, specification 3.2, Φ4.0, Φ5.0. The welding volume of ball and pipe space frame is large, which is equivalent to the standard welding seam of 22966m. Welders shall weld in strict accordance with the welding sequence and process parameters specified in the welding process card. In principle, the welding sequence extends symmetrically from the center to the outside, and the free deformation capacity of each member node is left during welding to reduce stress concentration. The material of the truss is Q345B, which is manually arc welded on site. The electrode is E56 type, the specification is Φ4.0, Φ5.0.

Dealing with complex joints due to the peculiar shape of the large steel structure roof, the design of space frames and trusses is very complicated, especially the design of connecting joints breaks some of the conventional joint forms. The main design includes the following types of nodes: the connection between the upper and lower chords of the space frame and the upper and lower chords of the main truss is connected by a ribbed hemispherical node; the middle chord of the space frame is directly welded to the middle chord of the truss; the vertical intersection of the space frame and the two-bar truss Connected by 1/4 ball; when the hemisphere cannot be placed, the space frame member can be directly welded with the truss; when the rod intersects, it is required to retain the thick tube and cut the thin tube. During the node construction process, the construction unit worked out a detailed installation process according to the complexity of each node, avoiding hidden welds and ensuring reasonable structural stress.

Shenzhen Civic Center’s large steel roof structure design welded ball space frame was installed on August 15, 2001, the first overall upgrade was successfully completed on November 9, 2001, and the second overall upgrade was successfully completed on February 6, 2002. The installation was completed on March 21. So far, the steel structure project of the big roof of Shenzhen Civic Center has been completed. The successful realization of the installation and overall improvement of the steel space frame of the roof of the Shenzhen Municipal People’s Congress has far-reaching significance. It has brought the domestic steel structure installation technology and overall technology to a new level.

First: There are more than 1,400 cones in this space frame welded ball space frame. During the steel roof structure construction process, due to the better control of each link of the assembly, the assembly error is reduced and the assembly quality is improved, which not only ensures the quality of high-altitude installation but also reduces In the process of construction, improving work efficiency and reducing construction period played a role that cannot be ignored.

Second: super-large trusses and space frames are assembled on the low-altitude full scaffolding in situ, reducing the large number of tire frames, which not only speeds up the progress of the project but also ensures the assembly accuracy.

Third: The space frame assembly adopts the method of accumulating from the center to the surrounding without a liner and plug rod, which can ensure the installation accuracy, and can protect the groove, and prevent the steel pipe from being knocked.

Fourth: The full use of computer technology in the optimal design of the space frame, material procurement, calculation of the length of the rod blanking, on-site rod management, intersecting line processing, etc., has certain advantages for the installation of similarly large and complex welded ball space frames in the future. reference meaning.

Fifth: The large steel roof structure design covered by the first overall lifting covers an area of 8400 m2, the weight is 1140t, 7 lifting points are set, and 19 sets of 40t and 8 sets of 200t hydraulic jacks are arranged; 2430t, with 13 lifting points, 15 sets of 40t and 17 sets of 200t hydraulic jacks. The second largest lifting area is the first in China, with 32 hydraulic jacks lifting and climbing mixed operation, which is also the first time in the history of domestic overall lifting.

Sixth: The completion of the large roof of the Shenzhen Civic Center has set a new record for the reticulated shell structure covering the largest building areachina.

About Us

About Us 2022-08-01

2022-08-01