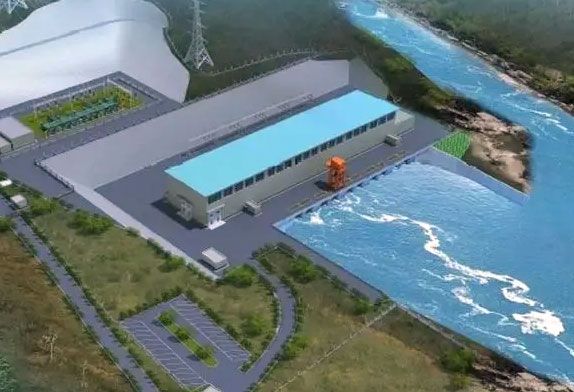

The supporting span of the main powerhouse of the Hydropower Station is 21.85m and the length is 132.65m. The steel consumption per unit area of the space frame structure is 29.5 kg/m². If steel roof trusses are used, it needs 55 kg/m2. The total steel consumption is saved by about 70 t. At the same time, the space frame structure rods and ball joints are convenient for mass production in the factory. The roof panel of the workshop adopts a double-layer sandwich composite steel plate, which greatly reduces the self-weight of the roof system of the factory. , which is more conducive to the lower load-bearing structure of the workshop. The main powerhouse of the hydropower station is one of the key structures of the water conservancy project, so the safety and reliability of the space frame structure of the powerhouse must be ensured first.

Steel space frame design

The mechanical characteristics of the space frame of the powerhouse of Wangfuzhou Hydropower Station is that it is supported on the upstream and downstream column space frame of the powerhouse, the powerhouse is long along the length direction, and the length-span ratio is about 6:1. Compared with the traditional steel roof truss, the space frame structure has a good overall spatial rigidity.

According to the layout of the column space frame of the workshop, the rationality of the internal force distribution of the space frame structure, the peak internal force of the members and their deflection values are analyzed and compared, and the structural form is selected as a positive square pyramid. Roof leakage will have serious consequences for the main powerhouse of the hydropower station. Therefore, a 5% double-sided slope is considered for the roof of the Wangfuzhou Plant to ensure smooth roof drainage.

There are generally two ways to lift the roof of the space frame structure: one is to start the slope from the top chord; The two methods have their own advantages and disadvantages. There are many specifications of the top chord and slope rod, and the angle between the inclined web rod and the chord plane changes is complicated, which increases the difficulty of manufacturing and installation of the rod and ball joint, but the internal force distribution of the rod is more reasonable. ; The main disadvantage of column sloping is that the structure of the upper chord node is complex, and the stability of the column itself is also a problem for the space frame with a large span and steep slope. Therefore, the sloping type of the space frame structure roof should be determined through a comprehensive comparison of economics and technology. Wang Fuzhou The main building of the hydropower station adopts the column-slope type, which is determined in order to facilitate the manufacture and installation of the space frame to meet the requirements of the construction period, considering that the span of the workshop is not too large.

The space frame size and height of the space frame should consider factors such as space frame type, span, column space frame arrangement, roof material, and structural requirements. JGJ7-91) The number of space frames and the height of the space frame are initially selected for the support of the top of the column, and the optimization is carried out by computer calculation. During this period, the relationship between the space frame size and the height of the space frame should be considered to meet the structural requirements of the ball joint.

Steel space frame installation

The installation of the space frame is closely related to the interference situation on the construction site, the hoisting ability of the installation unit, and the engineering experience and habits, and it needs to be determined after comprehensive analysis and comparison. space frame installation mainly includes high-altitude bulk scaffolding, strip or block installation, high-altitude sliding, overall hoisting, and other methods. The high-altitude bulk and strip or block installation method of full scaffolding requires a large amount of scaffolding to be erected in the factory building. The construction efficiency is low and when the space frame is installed, other constructions cannot be carried out at the lower part of the factory building; the high-altitude sliding method only needs to set up scaffolding in the inner zone of the factory building. , assemble part of the space frame in the scaffolding area, and remove it by using the sliding rails and hoisting equipment laid at high altitudes. Repeat this, and finally complete the installation of all the space frames. This installation method has less impact on the construction of the lower part of the workshop. It is suitable for the installation of the space frame of the workshop with connecting beams between the column space frames; the overall hoisting method is to use the lifting equipment to lift the assembled space frame to a high altitude after assembling the space frame with a larger area on the floor. This method can reduce the labor intensity of workers, and the installation efficiency and quality are high, but it requires a larger capacity of lifting equipment and interferes with the construction of the lower part of the workshop. The construction of the powerhouse of the hydropower station is characterized in that the upper and lower parts are carried out at the same time, that is, during the construction of the upper roof system, the installation of the lower mechanical and electrical equipment or other construction still needs to be carried out. Therefore, the installation method of the full scaffolding and the overall hoisting space frame installation method is difficult to meet the above requirements. The space frame of the Wangfuzhou workshop is supported by the top of the column, which is not conducive to the laying of sliding rails, so it is difficult to install by the high-altitude sliding method. For high-altitude platforms, scaffolding is set up on the bridge machine frame and reliable safety protection measures are taken for high-altitude bulk installation, which can not only meet the installation period of the space frame but also will not interfere with the installation of the lower mechanical and electrical equipment. After a comprehensive comparison, the high-altitude scaffolding method is selected for bulk installation.

About Us

About Us 2023-03-06

2023-03-06