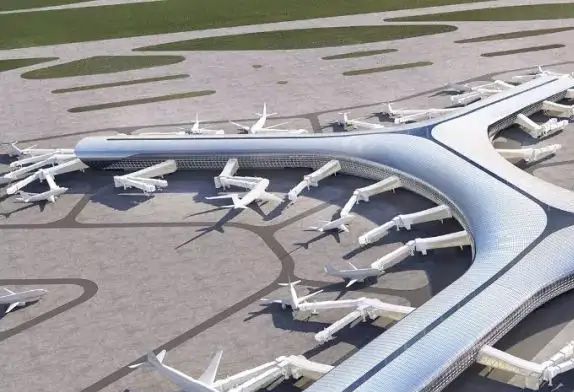

With the slow lifting and precise splicing of the last truss steel beam, the steel structure of the satellite hall of Shenzhen Bao’an International Airport has been fully capped, laying a solid foundation for the smooth completion of the satellite hall and its supporting projects. The satellite hall of Shenzhen Baoan International Airport has a total construction area of about 239,000 square meters and is composed of the central, southeast, northeast, southwest, and northwest corridors. The plane projection is in an “X” shape. The satellite hall is divided into four floors above ground and one underground floor, with 42 fixed-end boarding bridges. According to the plan, the satellite hall will be completed and put into use in 2021. It will be connected to the current T3 terminal through the MRT system, which will help further release the air and land resources of Shenzhen Baoan International Airport and better support the construction of a high-quality and innovative international aviation hub.

The steel structure of the satellite hall consists of lower rigid steel columns, roofs, and boarding bridges. The total steel consumption is about 23,000 tons, which is equivalent to half the steel consumption of the T3 terminal building. Among them, the maximum span of the roof is 90 meters, the roof steel structure is about 11,000 tons, and the projection area is about 76,000 square meters, which is equivalent to the size of 10 standard football fields. The steel roof structure of the satellite hall is an inverted triangular cross steel truss + a triangular cone welded spherical space frame structure. There are particularly many limbs in the assembly of rods and aerial unit assembly, and the structural deformation is large during installation and unloading. Through BIM technology, the whole process of steel roof installation is simulated, which solves the difficult problem of steel structure installation accuracy and deformation control.

About Us

About Us 2022-05-27

2022-05-27