In order to further improve the construction quality of the steel structure with bolt ball space frame structure, while strengthening the monitoring of the quality of the members, it is also necessary to strengthen the monitoring of the construction process, to avoid error accumulation, to enhance the stability and reliability of the steel structure, to ensure the overall safety of the building.

1. Preparation before installation

1.1 Material Management

After the steel structure material of the bolted ball space frame is processed, in order to improve the convenience of subsequent construction, the relevant staff need to classify and stack the components according to the model, type, and other factors according to the needs of the project construction.

Specifically, before the components are stacked, the relevant staff needs to place sleepers in the corresponding positions to avoid the corrosion of the components due to excessive moisture on the ground. Cover with plastic film and waterproof cloth, and make a mark to provide convenience for the access of components in the subsequent construction process.

1.2 Component Inspection

Before the components are used, the relevant staff needs to submit the bolt balls, rods, bolts, nuts, and other components for inspection in batches to avoid hidden dangers in the construction of the construction project due to the substandard quality of the components.

1.3 Trial assembly

Before the formal installation of the steel structure of the bolted ball space frame, the relevant staff also needs to check whether there are problems with the components by means of trial assembly. If there are problems, solve them in advance to ensure the convenience and reliability of subsequent engineering construction.

2. Installation steps

2.1 (1) Re-measure the axis and install the bracket; (2) Position the lower chord ball, lower chord, abdominal rod, Connect the chord joint and chord rod, and correct them; (3) Tighten all the bolts and Carry out self-inspection on it; (4) hoist the space frame and side space frame, adjust the axis of the space frame and Carry out self-inspection; (5) Weld the space frame support.

2.2 Measurement positioning and support installation

(1) Before installing the steel structure of the bolted ball space frame, the staff must first measure and locate the center point of each support; (2) After ensuring that the center point meets the construction requirements, draw the position of the center axis; (3) ) Referring to the positioning axis, use a crane to place the support on the embedded part at the top of the column; (4) Use the theodolite to measure the position of the support, and fix the support in the corresponding position after ensuring the correct position.

2.3 Space frame assembly

(1) The staff needs to be familiar with the types, sizes, and corresponding positions of all bolt balls and rods in the design drawing and check the rods. If the rods are found to be bent and deformed during transportation, storage, and hoisting, It needs to be corrected.

(2) The staff needs to check the markings of the rods and bolt balls against the design drawings and start the installation work after ensuring that the markings are correct.

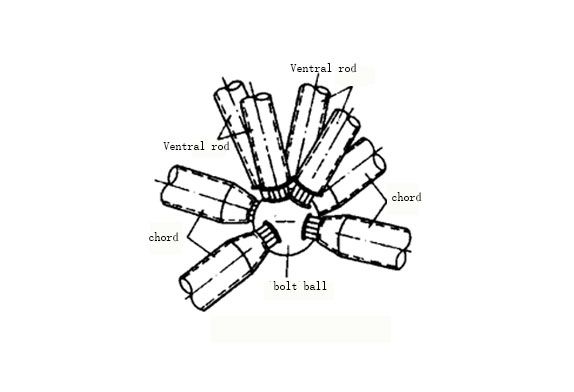

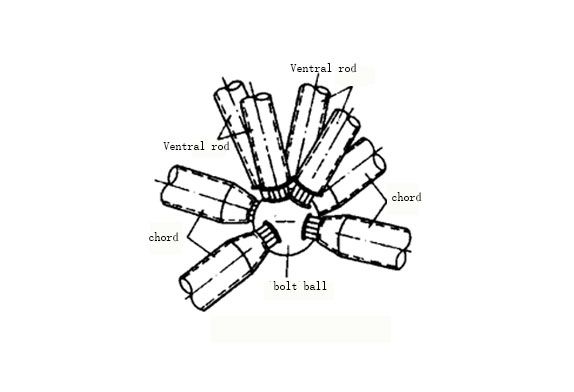

(3) The installation work of the steel structure of the bolted ball space frame is mainly the installation of bolts and balls (Figure 1). During the installation process, in order to ensure that the quality of the structure after installation meets the installation requirements, the staff must ensure that the friction surface of the connecting components is clean and dry. , and ensure that the high-strength bolts are in the same direction when they smoothly penetrate the ball holes.

Figure 1 bolt ball

(4) In order to improve the connection tightness of the bolts, the staff needs to tighten the bolts two times, and each group of high-strength bolts must be tightened on the same day, and it is strictly forbidden to leak. Specifically, the steel structure of the bolted ball space frame mainly includes two types of space frames: plane and curved, and its support methods include multi-point support, two-sided support, and peripheral support.

Among them, the upper chord of the flat space frame is generally a pressure rod, and the lower chord is generally a tie rod. On the whole, the combined scale of the upper chord is larger than that of the lower chord. During the installation process of the space frame, the self-weight deformation of the rod may occur, which is unfavorable to the subsequent construction. influence. In order to solve this problem, during the construction of the steel structure of the bolted ball plane space frame, the staff can replace the sliding construction with full-scale scaffolding. While ensuring the personal safety of the construction personnel, it can avoid the support and pre-buried caused by the subsidence and deformation of the space frame. deviations between parts. For the curved space frame, because the radial rods of the space frame is mostly pressure rods, and the construction difficulty of the pressure rods is much greater than that of the tie rods, the staff must avoid stress on the tie rods before the overall installation is completed.

Product Category

Product Category

Chat with us

Chat with us

Leave a message

Leave a message