1、Main features of dome coal storage shed:

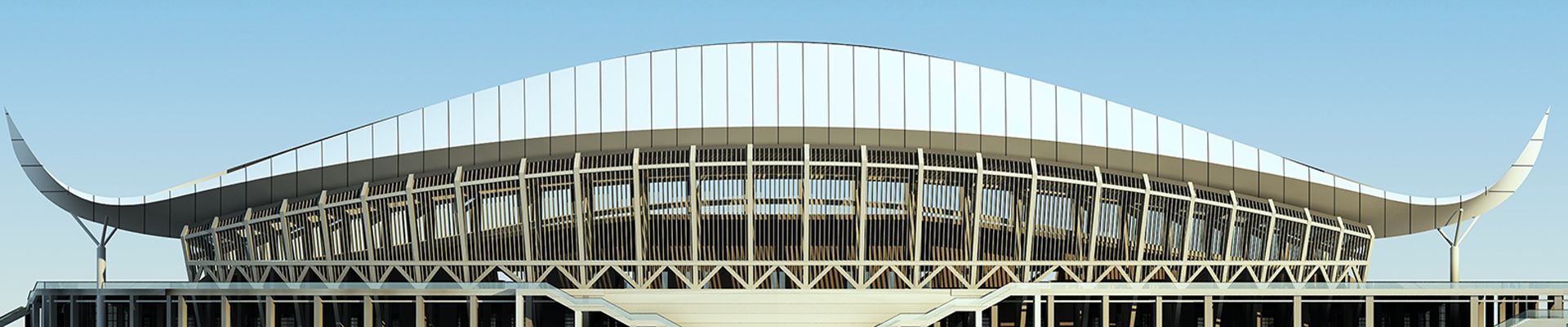

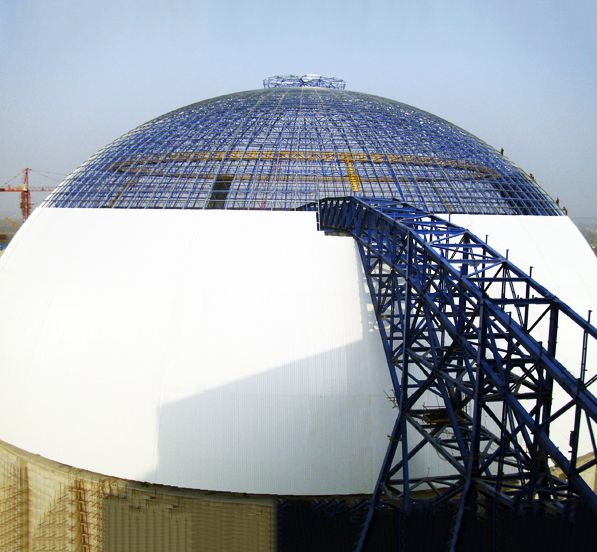

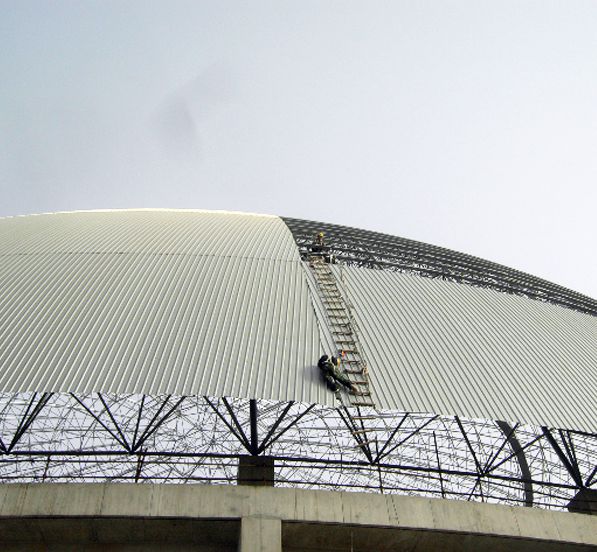

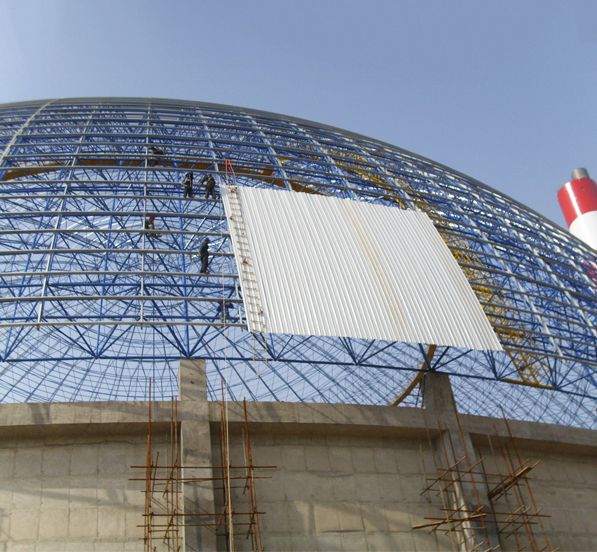

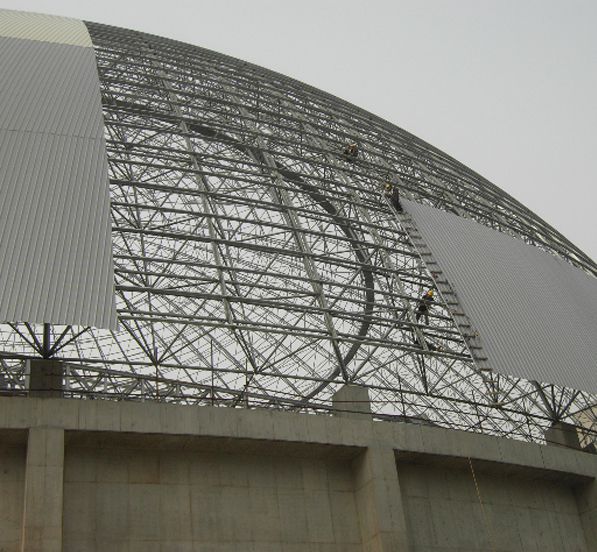

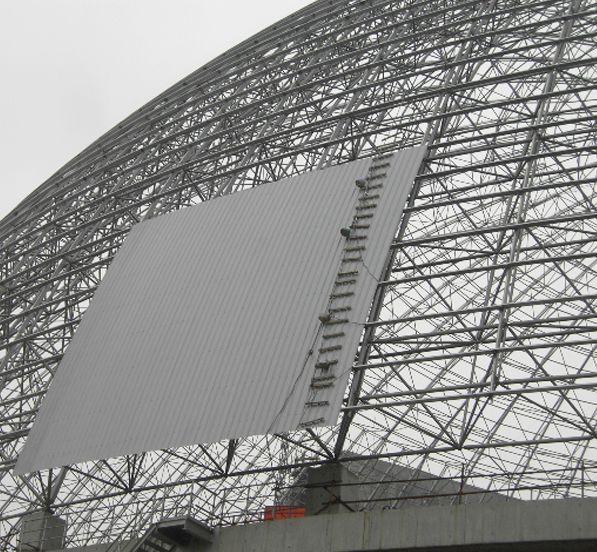

Dome bulk storage is a kind of storehouse that is used for storing coal in thermal power plants. Dome coal storage yard is an environment-friendly coal storage mode, which is characterized by full closure, beautiful appearance, no pollution, and is not affected by weather conditions. It is adopted in power plants built around the city.The closed circular coal yard and equipment, with advanced technology, a high level of program control, and outstanding environmental protection performance, are commonly used in the world and have been operating for decades. Therefore, the safety and reliability of circular coal yards have been fully verified.

(1). The environmental protection performance of the circular stockyard is outstanding, which better solves the problem of pollution of the storage yard to its surrounding environment.

(2). The dome stockyard has advanced technology and a high level of program control. The highly automated operation of the circular stockyard greatly improves the production efficiency and reliability of the entire coal handling system and improves the automation level of the large stockyard.

(3). The construction area of the circular stockyard is small and the utilization rate of the site is high. The amount of earth and stone is much lower than that of the long stockyard, especially for the civil construction that needs to be reclaimed.

(4). Avoid the impact of bad weather on the safe operation of the coal storage plant. Generally, wind and rain in the stockyard have a great impact on the material, which further affects the material conveying system, and the circular stockyard with a fully enclosed structure has a great protective effect on the material. Engineering, civil engineering advantages are more obvious.

(5). The coal yard operation can realize the “first-in, first-out” stacking operation principle, which is updated according to the spontaneous combustion cycle of coal, which can effectively prevent the spontaneous combustion of coal piles in the coal yard. The reclaimer removes the coal in the coal yard, and the remaining coal in the dead corner is very small, and the workload of auxiliary operations in the coal yard is small.

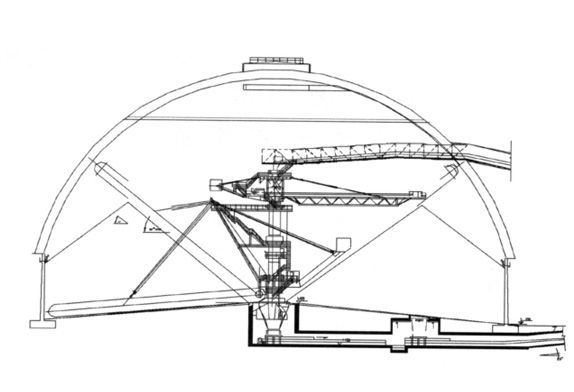

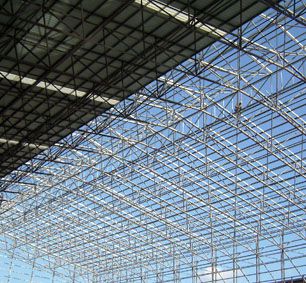

2、There are many coal storage methods. The space frame structure of the coal storage shed requires a large span with flexible height, to meet the storage and working space requirements. Due to the special requirements, the space frame structure is almost the only choice of coal storage, especially with large span and free height, we can realize and improve its looks grand, magnificent, and aesthetic. Meanwhile, there are multiple structural forms of space frame coal storage shed, the building subject is made up of arched space frame, the length and width are determined by the internal installed capacity, and the width is determined by the operational requirements of the bucket wheel machine working for coal pile.

3、The space frame structure can also be used for the building roof system of gymnasiums, theaters, exhibition halls, waiting halls, bleachers of the stadium, hangars, two-way large column space workshop, etc.

4、Compared to the node structure, the construction process of the space frame is more complicated, which requires a more professional team to supervise.

Product Category

Product Category

Chat with us

Chat with us

Leave a message

Leave a message

Download

Download