The space frame structure has the advantages of being lightweight, high rigidity, good seismic performance, flexible installation method, and ease to improve processing and installation quality of components. At present, thousands of space frame structures have been built in my country. In recent years, the roof structure of domestic hydropower plants has gradually begun to be used, and the use of space frame structures has been increasing day by day.

1.1 Power Plant Warehouse Project Overview

Space frame: positive quadrangular cone bolt ball joint space frame, space frame number = 6 × 21.

Support form: point support around the upper chord column (except for the wind-resistant column, all are flat-type rubber bearings).

Node form: Bolted ball joints and the rods are made of copper tubes.

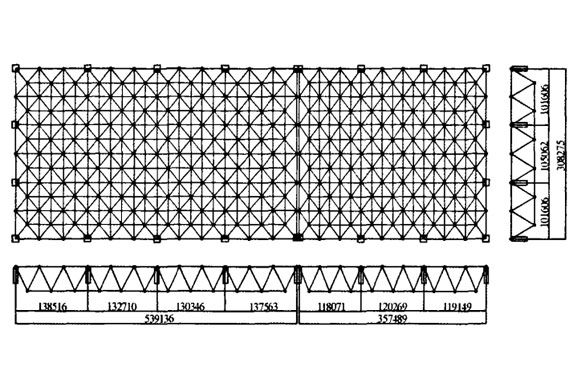

Geometric dimensions: span 22.3m, length 65.18m, height 1.9m, span-height ratio ≤12. Roof form: light roof, the slope is 3%, and the slope drainage structure form on both sides is shown in Figure 1.

Figure 1. Structure diagram of the space frame structure of the powerhouse of the pumped storage power station

Main lifting equipment: 25t, Tiantai gantry crane. Its main technical indicators are: the maximum lifting weight is 25t, the maximum lifting net height is 40m, the maximum amplitude is 42m, and the maximum lifting weight at the maximum amplitude is 10t.

1.2 Space frame installation construction scheme

The space frame installation schedule of this project is tight, the power plant warehouse construction site is narrow, the environment is complex, cross-operation is required, and the construction conditions are simple. It can cover part of the installation parts of the space frame, etc., there are certain difficulties in the installation of the space frame. For this reason, the method used in the construction of the space frame is that the weight of the ground assembly of the space frame should be less than or equal to 10t. The installation of the space frame is divided into the production and installation of pre-embedded parts, ground assembly of the space frame, overall hoisting of the sub-sections, in-position (sliding) ), air connection (bulk), support connection device welding, roof installation, etc.

1.3 Installation of space frame structure

1.3.1 Fabrication and installation of embedded parts of supports

The embedded parts of the support are generally produced and installed on-site by the civil construction unit, or they can also be produced by the space frame installation unit on-site and installed in conjunction with the civil work. The surface of the embedded parts is required to be flat.

1.3.2 space frame ground assembly

(1) The assembly site is required to be flat and barrier-free and can meet the requirements of the lifting equipment for the position of the lifting point and the requirements of the plane geometric size of the sub-assembly space frame.

(2) Classification of rods and bolt balls. Clean up, classify and stack the rods and bolt balls in sequence according to their specifications, models and numbers, take out or knock down all the screws at both ends of the rods, and pre-assemble the sleeve together with the anti-rotation screws (Note: the screws Do not screw it to death, it is advisable that the sleeve can slide slightly on the screw so that it is convenient, fast, time-saving and labor-saving when using. Although this is preparatory work, it is very important to improve the efficiency of subsequent rod installation and should be paid special attention.

(3) Assembly of the space frame. Assemble the rods and bolt balls into small units according to the design numbers, and then assemble them one by one in strips or blocks. It is also possible to assemble the bottom chord members of the sub-space frame at one time, and then assemble them unit by unit by strips or blocks. It should be specially pointed out that the connection between each rod and the bolt ball connection bolt should be tightened, and there is no gap at both ends of the sleeve; because the number of each rod and bolt ball of the space frame is unique, so each rod The assembly number of the bolt ball must not be misused or interchanged, otherwise, it will directly affect the overall quality of the space frame assembly and the stress of the space frame structure. According to the lifting capacity of the crane, the support on the floor can also be installed together with the roof purlin to reduce the amount of work at heights as much as possible.

The ground assembly weight of the space frame of this hydropower plant is less than 10t.

1.3.3 Lifting and sliding of the space frame roof

(1) The focus of the hoisting of the space frame is the selection of lifting equipment and the selection of lifting points. It requires safety, reliability and stability. The lifting weight must have a certain degree of safety. After the space frame is hoisted, it cannot produce permanent deformation and maintain a certain degree of safety. level.

(2) For the position that cannot be covered by the lifting equipment, the slideway made of profiled steel can be pre-laid on the top of the column or the ring beam. After placing the space frame on it, the two ends are pulled and slipped by hand hoists or hoists at the same time. And take care that both ends stay in sync. In order to reduce the friction of the slideway, an appropriate amount of calcium-based grease and other lubricants can be applied to the surface of the slideway.

1.3.4 Air connection of space frame

Due to the location of the civil works and the installation sequence, a small number of space frame members and bolt balls must be installed in the air. At this time, only the high-altitude bulk method can be used for installation and construction, but special attention should be paid to strengthening safety measures for high-altitude operations.

After the overall positioning of the space frame and the welding space frame are all installed, if any dislocation is found, the chain hoist can be used to adjust and position. After the acceptance is qualified, each support device can be welded with the embedded parts in sequence.

1.3.5 Space Frame Roof installation

Roof installation is relatively simple, and its installation procedures are generally: purlin installation, bottom profiled board installation, insulation layer (rock wool) laying, surface laminate profile installation, roof ridge installation, leak-proof treatment, etc.

1.3.6 Purlin system installation

The installation of the roof purlin system mainly depends on the lifting capacity of the lifting equipment. If the hoisting capacity permits, it can be installed and welded together (or part) with the space frame on the ground, and then hoisted at one time. This method is not only safe, efficient, but also easy to ensure quality. If the conditions do not allow, all (or part) of the installation and welding can be carried out in the air, but this method has high risks and low work efficiency.

1.3.7 Installation of profiled roof

The general installation procedure of the profiled roof: (1) Lay the bottom ridge first, then lay the bottom profiled boards on both sides, and fix them firmly with rivets; (2) Lay the insulation layer; (3) Lay the profiled boards on both sides of the top layer respectively, and use self-tapping screws to fasten the upper and lower laminates together with the insulation layer firmly without loosening. Finally, install the top ridge and fix it firmly with pull rivets.

1.3.8 Leak-proof treatment of the roof

The leak-proof treatment of the roof is mainly the leak-proof treatment of the gap between the ridge and the profiled plate and the gap between the tail of the self-tapping screw and the profiled plate, which is generally solved by applying or filling water-stop glue. In this example, the method of applying silicone glass glue is ideal.

The installation of the space frame structure of the hydropower station has both the general rules of the general space frame installation and the characteristics of the construction of the hydropower station. Giving full play to and utilizing the features and advantages of hydropower plant construction, and using existing technologies and equipment flexibly and comprehensively, can not only greatly improve work efficiency and reduce costs, but also more easily ensure the quality and safety of its installation.

About Us

About Us 2022-09-30

2022-09-30