The main part of the toll station is the toll station canopy, and the special function of the toll station determines some structural dimensions of the toll canopy. First, the width of the toll canopy perpendicular to the road surface should be greater than the width of the road surface where the canopy is installed; secondly, the width of the toll canopy parallel to the road surface should be greater than 14m; finally, in order to meet the smooth passage of vehicles under it, the clear height of the toll canopy should be greater than 5 m. .5m. Some of the above structural dimensions and use functions also determine some specific characteristics of the toll station structure.

The main part of the toll station is the toll station canopy, and the special function of the toll station determines some structural dimensions of the toll canopy. First, the width of the toll canopy perpendicular to the road surface should be greater than the width of the road surface where the canopy is installed; secondly, the width of the toll canopy parallel to the road surface should be greater than 14m; finally, in order to meet the smooth passage of vehicles under it, the clear height of the toll canopy should be greater than 5 m. .5m. Some of the above structural dimensions and use functions also determine some specific characteristics of the toll station structure.

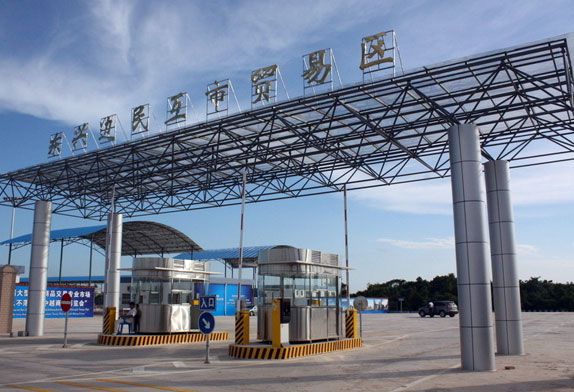

- Since the width of most toll stations perpendicular to the direction of the road is greater than the width of the direction parallel to the road, the plane projection shape of the toll stations is mostly rectangular. A square plan form is only possible unless the toll booths have fewer lanes and the road they span is not wide, but this is rare.

- In order to meet the needs of vehicle traffic, the support columns of the toll station perpendicular to the road surface cannot be arranged too densely. Generally, the support columns should not be set within the width of the road surface as much as possible, and the support columns should be set outside the width of the road surface. A completely open and unobstructed space is formed within the width.

The following types of large-span space steel structures are often used in toll stations.

1) Lightweight steel structure

The single-layer portal frame is generally a structure with rigid nodes composed of linear members (beams and columns). This type of structure has fewer rods, and the internal space of the structure is large. At the same time, the rigid frame is generally composed of linear rods, which is convenient to manufacture, and the amount of steel used is less (usually 30kg/m), and the cost of the structure is low, but The shape of such structures is relatively simple.

2) Flat space frame structure

The flat space frame structure is a network structure composed of many rods according to certain rules. The pipes are mostly made of round steel rods or angle steels, and the joints are mostly welded hollow ball joints, bolt ball joints and steel plate welded joints. The amount of steel used is small, the space frame with a small span can reach 6~7kg/m”, and the grid frame with larger span generally does not exceed 20kg/m”, which is a structural form with very good economic performance.

3) Space-reticulated shell structure

The reticulated shell structure is a net-shaped shell structure or a curved grid structure. The reticulated shell structure has a beautiful shape, good mechanical performance, and superior technical and economic indicators. The structure is applied to the structure of the toll station, which can meet the requirements of changing architectural shapes, and is a good structural form.

4) Prestressed cable-stayed space frame structure

Academiç Journal E prestressed cable-stayed grid structure is to connects the grid or lattice shell structure with the tower column through the stay cable. This type of structure is a structural system developed on the basis of space frame and reticulated shell structures. The existence of stay cables enables such structures to span larger spans, and also makes the grid or reticulated shell structure stressed. more reasonable.

5) Cable-membrane structure

The cable-membrane structure is a new structural system developed in recent years. Such structures are divided into two structural forms: one is a suspended membrane structure; the other is a space frame membrane structure. Both of them use steel cables and steel members as the main load-bearing structures to transmit external loads on the membrane surface. Due to the high plasticity and various shapes of the flexible cable and film, the prestressed structure has sufficient rigidity and can meet the load-bearing function, and has lightweight, good light transmission, and strong modernity. Therefore, the use of cable-membrane structures in toll booths The prospects are very broad.

About Us

About Us 2022-10-09

2022-10-09