1、Coal storage dome shed project overview

The closed structure part of the large prefab metal shed mainly includes the space frames roof, the reinforced concrete coal retaining wall, the trestle entering the warehouse and the tunnel exiting the warehouse. The spherical reticulated shell and the top protruding part are closed with galvanized colored (double-sided) single laminated steel plate. The reticulated shell part adopts a space frame structure. The spherical reticulated shell on the upper part of the dome coal storage adopts a rib-ring type quadrangular pyramid spherical reticulated shell structure. The nodes are connected by bolt ball joints. The thickness of the reticulated shell depends on the strength, deflection, and drainage of the structure. Economic requirements Sure. The diameter of the circular coal yard is 127.394m, and the top elevation of the retaining wall is 22.00m. The support method of the reticulated shell adopts the point support method of the lower chord column, with 36 supports, each 10° corresponds to support, and the center of the support is arranged on a circle with a diameter of about 121.3m.

2、Features and difficulties of this steel structure project

The diameter of the sphere in this project is large, reaching more than 120m. The maximum outer diameter of the space frame rod material is 180mm, the wall thickness is 8mm, the minimum outer diameter is 75.5mm, and the wall thickness is 3.75mm. The maximum diameter of the bolt ball is 300mmmm. The space frame has a large amount of on-site assembly. The installation accuracy is high, and the installation radius is large. The construction of this metal shed workshop project is difficult. The height of the retaining wall reaches 22m, which increases the overall height of the space frame. Such height and diameter are rare in the whole country. It also includes the restrictions of the construction site and the sea breeze and rainwater. etc.

二、the main space frame dome bunker construction technology

1、The general idea of space frame installation is due to the novel structure of this project, which is a hemispherical dome shed. According to the characteristics of the special-shaped space frame in this project, it adopts the principle of “adopting small pre-assembled units on the ground and then using truck cranes and self-designed independent space frames. The bottom ring is hoisted by strips and blocks, and the bottom ring is hoisted in the air, and most of them are hoisted by cranes and small spreaders. The cone is installed and closed layer by layer. The space frame structure of this scheme is reasonably stressed during installation, and the construction is safe and reliable; the construction speed is fast and the construction period is short.

2、Space frame construction technology

First, re-test the embedded parts at the top of the silo wall of the dome coal bunker. The bottom ring frame is divided into 18 blocks according to the support, and each block is composed of 5 upper chords, 5 lower chords, and web bars. Then use a 50T truck hoist to hoist the block into place. Since the space fame is single-row support, the stability is poor before the bottom ring is closed. The space frame block reaches the design level and is stable. Then, the adjacent blocks are hoisted in sequence and docked in the air, and temporary supports are added at the same time. And so on, until the bottom ring space frame is closed. It is very important to pay attention to the space frame installation of the bottom ring, which is equivalent to the benchmark of the entire space frame. Precise installation is convenient for subsequent installation, otherwise, the error will become larger and larger. This requires strengthening the measurement and inspection during the installation of the bottom ring space frame, including the size of the assembled blocks, the degree of bolt tightening, and the elevation of the frame. After the bottom ring mesh frame is closed and checked to meet the requirements, the mesh frame support is segmented and fixed temporarily to form a whole, which is convenient for subsequent installation. The space frame installation is then closed layer by layer from bottom to top. This part of the installation adopts the hoisting cone high-altitude bulk method, which is convenient for workers to operate and install quality.

Dome steel building construction steps:

The space frame steel structure installation and construction scheme is the cantilever installation method of small splicing units, that is, the installation sequence of progressive bottom-up and closing from the outside to the inside, which belongs to the construction of the internal expansion method, and the installation sequence is as follows.

1) The installation step of the first circle of the reticulated shell structure is to firstly pre-assemble the pieces on the ground. Each piece includes all the components of the first circle of the lower chord and the first and second circles of the upper chord between the three columns; check the delivery list and installation The picture is to count the components that enter the site, and then organize the feeding according to the order of installation of the space frame, and put ingredients on the working platform, then assemble the tripod, and push the tripod to assemble the small units of the frame.

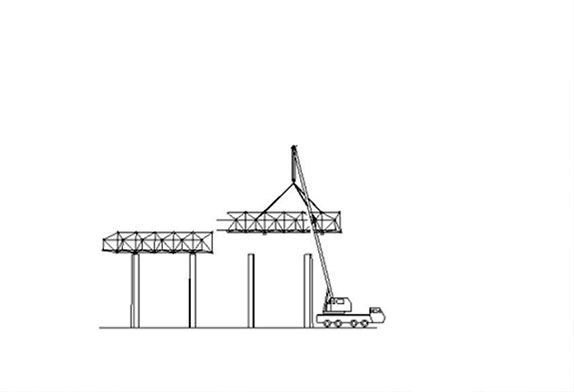

2) Hoist the pre-assembled sub-units into place with a truck crane, as shown in the figure below, and temporarily fix them with cables and wind ropes after they are in place. Due to site conditions, the crane can only hoist the pre-assembled three parts. Each small block unit is hoisted into place, under the unified command of the captain, the team members find the support, install the corresponding ball and rod to form a certain rigidity, and then use the scaffolding and the three already installed blocks units. Use independent pull rods and hoists to complete the rest of the bottom ring frame until the entire bottom ring is closed. During the construction process, self-test and self-inspection should be organized in time. The bolt connection parts should be tightened in place, and the position of the space frame should be adjusted strictly. The offset is strictly controlled within the allowable error.

3) The installation method of the second to eighth circles is the same as that of the first circle, as shown in Figure 1.

FIG.1 Schematic diagram of lifting starter unit

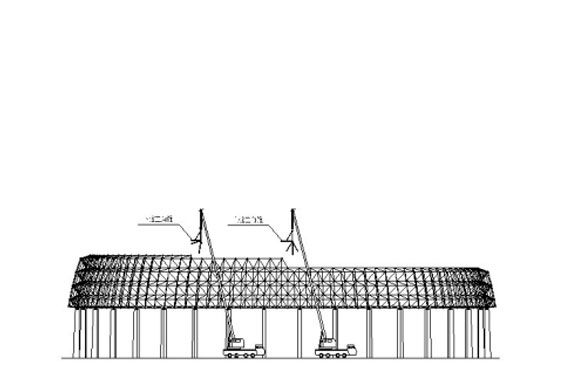

4) From the 9th circle to the 18th circle, since the installation height exceeds the allowable working height of the rated truck crane, at this time, it will be considered to use the triangular cone hoisting and cantilever installation with a single-leg pulling rod and a hoist (as shown in Figure 2).

FIG.1 Schematic diagram of triangular cone hoisting (applicable to elevation below 40M)

5) The top cover part of the dome steel structure building is a dome flat space frame. The installation method adopts the high-altitude bulk method. First, pull the steel cable on the installed open shell, lay the scaffolding board to form the working surface, and then put the top cover part. All components are hoisted to the working surface by a hoist and assembled by workers at high altitudes.

6) After the space frame steel structure is installed, a closed and complete spherical reticulated shell is formed. After the purlins and roof panels are transported in place by the high-altitude bulk method, workers will weld and install them at high altitudes.

About Us

About Us 2022-07-22

2022-07-22