The roof form of stadium building is usually closed structure. As the span of the gymnasium building is generally large, the use of steel space frame structure, not only with a small amount of steel, good integrity, rigidity, and can create a large structural span and depth, so as to meet the required building space of the gymnasium. Steel space frame project has the above advantages, but also to the production, processing, installation brings greater difficulty, and then create a greater safety risk to the construction. This paper combines a gymnasium steel space frame structure installation project to explain how to start the supervision of steel space frame structure installation project and reduce the corresponding quality and safety risks.

1、Project overview

This project is a multi-storey gymnasium building, with a total construction area of 19504m2; including 7339m2 underground and 12615m2 above ground. 1 layer underground and 3 layers above ground, with a building height of 23.9m and frame structure. The first floor is for general physical education rooms, including gymnasium, table tennis room, dance room, meeting room and press room and other functional rooms, with a floor height of 3.5m; the second floor is for indoor gymnasium rooms, with a floor height of 20.4m. The distance between the center of the lower chord of the space frame and the structural surface of the concrete floor on the first floor of the project is 15.85m.

2、Steel space frame structure installation project characteristics, risk analysis and supervision control objectives

2.1、Features of steel space frame structure installation project

The roof steel space frame structure project adopts the form of bolted ball node space frame, the space frame span is 67.2m×58.8m, and the space frame installation height is 21.57m (column top support surface). The main components of the bolted ball space frame are processed and produced in the factory, and then assembled directly at the construction site. This can ensure the construction accuracy and the consistency of the space frame structure. The roof of the project is sandwich composite panel with steel purlin. The space frame of the project is installed by overhead bulk method on full scaffolding.

2.2、Risk analysis of steel space frame structure installation project

The steel space frame structure of this project adopts the form of bolt ball node, and the main components of the space frame are processed and made in the factory. If the processing accuracy and quality of the main components do not meet the quality standards, the deflection value of the space frame project will not meet the provisions of the design and acceptance specifications after the completion of on-site assembly, and the mesh frame project will not meet the quality acceptance standards, and there is even a serious potential risk of collapse of the space frame structure. Steel space frame in the installation process, the temporary support points should be set to be treated seriously. If the temporary support points of the mesh frame are not properly arranged, it will lead to the uneven force of the mesh frame in the installation process and the inconsistent force of the bars, which will easily cause the temporary support points and the mesh frame structure to deform, sink and other problems, thus leading to the occurrence of safety and quality accidents. Temporary support of steel space frame structure installation project is set on the ground floor concrete slab, if the load on the upper part of the ground floor concrete slab is not checked, once the load of the temporary support structure exceeds the allowable load of the floor, it will inevitably cause damage to the structure.

2.3、Control objectives of steel space frame structure installation supervision work

2.3.1、Quality control

Based on the specific requirements of quality inspection of each subdivision project, combined with the specific requirements of supervision process control, the key processes of quality control and their quality control targets in the construction of each subdivision project of steel mesh frame engineering are clarified, and the control means or measures of key processes are further determined, so as to ensure that the construction quality of steel mesh frame engineering reaches the standard of once acceptance.

2.3.2、Progress control

In order to ensure the smooth progress of the steel space frame project, it is necessary to clarify the key processes of progress control in the construction of steel space frame project and the related control means or measures, so as to control the deviation of the actual construction progress of the steel space frame project from the planned total construction progress within the controllable range, and to pre-estimate other factors (such as climate, environment, etc.) that will have an impact on the construction progress and prevent them in advance, so as to reduce their impact to the minimum degree.

2.3.3、Safety control

The steel space frame installation project belongs to the construction of the more dangerous parts of the project, the safety supervision of the construction process throughout the steel space frame construction process, the supervisory body must require the construction unit to identify and evaluate the risks of the steel space frame installation project, and take appropriate measures to pre-develop the emergency plans for safety management, so as to reduce the probability of safety hazards and safety accidents in the steel space frame construction.

3、steel space frame structure installation project construction program review points

The special construction plan of the steel space frame project should be based on the characteristics of the structural engineering, combined with the surrounding environmental working conditions during the installation of the steel space frame project, the reasonable choice of installation construction process methods, and the reasonable choice of lifting machinery and working platform, so as to determine the installation plan. Supervisor shall review the construction plan on the following key matters.

3.1、The main points of the review of the construction method of the space frame project are as follows.

(1)Review the on-site installation method of the space frame project, which adopts the overhead bulk method on full scaffolding.

(2)review the space frame installation and construction of the flow operation method, etc.

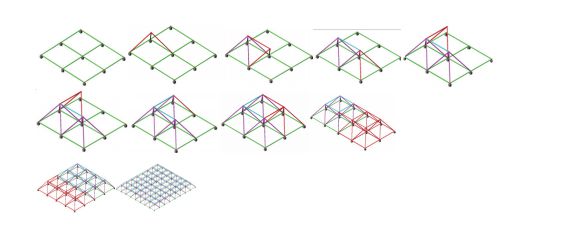

(3)Review the construction measures of the space frame project, such as scaffolding construction plan, temporary support construction plan, etc. The flowing demonstration of steel space frame project installation is shown in Figure 1.

Fig. 1 Flowing demonstration of space frame project installation

3.2、 Preparation work before the installation of the space frame and roofing

The review points are as follows.

(1) Preparation of technical documents for steel space frame and roofing installation construction.

(2) The strength values of all the pre-buried parts of the supporting surface when the steel space frame is installed in the field.

(3)The condition of temporary facilities such as construction roads and material storage sites around the site.

(4)The top elevation and longitudinal and transverse plane axis dimensions of the pre-buried parts are retested before the steel grid is installed and confirmed to be qualified before installation.

(5) Construction organization deployment. Including: construction force (technical management personnel qualification, special work personnel qualification, health condition of construction personnel, etc.), construction machinery, collection of technical conditions, adjustment and preparation, etc.

3.3、Preparation for the installation of the space frame

The review points are as follows.

(1)、After the material arrives at the site, the installation preparation work such as selecting the rod, bolt ball and upper sleeve is carried out according to the factory list of the processing plant, and the installation team should prepare for the installation by conducting axis positioning and elevation measurement of the pre-buried parts provided by the civil construction party according to the installation drawing.

(2)、Before the steel space frame installation, the fixed axis line and column top elevation of the steel space frame support reference surface (support surface) should be reviewed and accepted.

About Us

About Us 2023-08-28

2023-08-28