1、Basic situation of the cover structure of the cliny library steel space frame

The structure project of the steel space frame cover of a Cement Factory’s Steel Library, the main environmental load parameters: the earthquake -resistant defense intensity is 8 degrees, the design of the basic seismic acceleration is 0.20g,and the group is the third group; the basic wind pressure is 0.65kn/m2, the basic wind pressure There is no snow lotus. The cover of the Steel Steel Gallery of the Cliny Library is divided into two parts: the top of the top library top house and the lower edge of the edge (the stacking process line requirements). The top library on the upper part of the clinic library is 25.000m, the size of the embedded parts is 30mm × 700mm × 700mm, and the material is Q355B. The diameter D2 =15.000m of the dangling house is 59.500m. The height of the eaves is 59.500m. The diameter of the lower edge (shell) diameter is DI = 60.650m,and the space frame height of the space frame structure is 19.880m.The welding ball is used at the bearing connection to effectively control the maximum connection bolt diameter used by the main structure. The maximum bolt model used in the entire network is M56 (9.85). The steel platform is the combination of H -shaped steel beam truss and space frame. The top label height of the steel beam is 46.000m, and the H -shaped steel beam is 5mm thick. , The roof is paved with 4mm thin steel plate waterproof. The comprehensive steel volume of the clinic library and the top house of the library is approximately 65kg/m2 (excluding steel platform H -type steel beam system).

2、Design of clinker warehouse steel space frame roof structure

2.1、Necessity of improvement of clinker warehouse space frame roof structure design

The steel structure system of the cliny library edge has gone through the development process from the central cylinder to the free center of the art -bar, from the truss system to the space frame system. (Shell) The system has been applied in the construction of a cliny library. At present, the top house of the library library in the library house not only has a space frame system, but also a light steel system. Because the top house of the database is a secondary maintenance structure, its steel volume is small, the design is mature, the method is simple, and the space can be optimized. Essence the structure design of the routine cooked database ridge space frame structure is all bolted ball nodes. Due to the special working environment (high temperature, equipment vibration load) 5 in the cliny library, large diameter bolts (M60 ~ M85 are all all near the support. There are) resistance ring internal force. During the construction of large bolts, it is difficult to tighten, and the phenomenon of false tightening occurs. There are very large hidden safety hazards. From the perspective of security, it is necessary to reduce the diameter of the bolt and improve the design of the structure.

2.2、Thinking of the improvement of the cover structure of the clinker library steel space frame

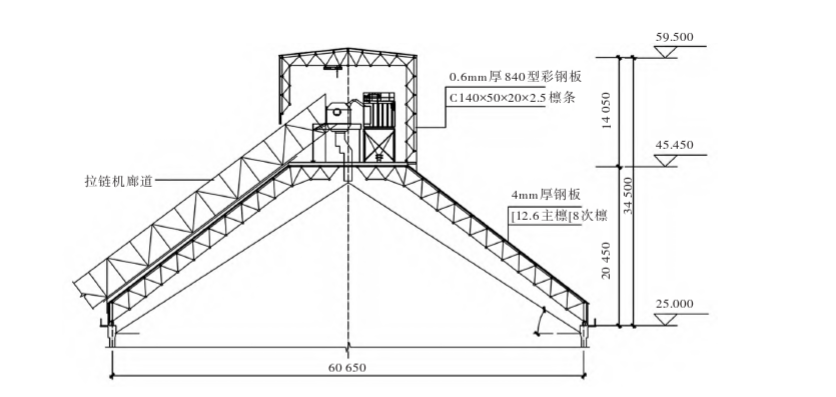

Large diameter clinker library top space frame (diameter D> 60M) must use finished sliding support support or spring support to reduce the radial branches, thereby reducing the impact on the structure of the concrete cylindrical warehouse, to control or reduce the total engineering total Cost. According to preliminary analysis of previous experience, the project of the unidirectional sliding support of the project is 6.0kn/mm, the radial support is required <260kn, the horizontal displacement limit allowed by the elastic sliding steel parts to support At about one thousandths, the steel platform in the limit use is small, and the steel platform is small in the limit state, providing good working conditions for equipment operation. The stand -up standing of the top network of the top of the luga, the ring rod is connected by welding the ball (its diameter is controlled as D <500mm, and a stretch rib that the ball is the same as the ball’s wall), the ball ball (pole and welding ball ) The weld quality control level at the connection is first level, and 100%ultrasonic detection must be performed; large bolt construction difficulties, low reliability, and the maximum bolt diameter of the entire space frame structure <M60. The welding ball is hollow and is sold by the two hemisphere docking group. The quality should meet the 5.2 regulations of JGJ7-2010 “Technical Regulations on Space Frame”. The design section of the hits of the hits steel space frame cover is shown in Figure 1.

Figure 1 Steel structure design profile of clinker depot

Figure 1 Steel structure design profile of clinker depot

2.3、Calculation of space frame structure calculation of bolt welding (bolt ball and welding ball)

(1) Use Zhejiang University MST Software to design the frame design and draw a detailed construction diagram; use Tongji University 3D3S software to establish an overall steel structure model for review analysis, and test the strength of the welding ball node. The basic control parameters of the edges are: 150 in length ratio of the stretch rod, the stress ratio of 0.90, the steel pipe is made of Q235B, the start section size is 476mm × 3.75mm, and the structural deflection is <65mm8. The basic control parameters of the Genfang House space frame are: the length ratio of the pressure rod is 180, the stress ratio is 0.93, the steel pipe is made of Q235B, the start section size is ф60mm × 3.50mm, and the structural deflection is <35mm.

(2) The local conditions of the project where the project is located is large, and the impact of wind loads on the structure must be fully considered. “After 3D3S software calculations, the wind load parameters of the storage steel space frame are analyzed.

(3) The location of the project is a high -intensity earthquake area. The vertical and horizontal seismic check calculation of the space frame (shell) is carried out according to the current space frame rules. The modal analysis is that the first four levels are flat vibration type, the main vibration cycle is 0.45s, and the vibration cycle is attenuation slow; When analyzing this grid (shell), take the previous 25 vibration type to perform effect combinations. The clinical library space frame 1 vibration type, second vibration type, and 5 vibration type diagram are shown in Figure 2 ~ Figure 4, respectively.

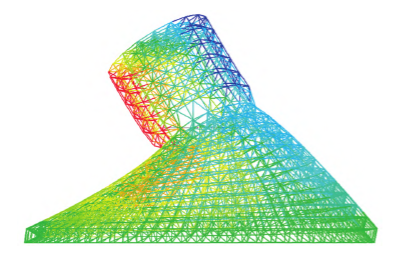

Figure 2 First vibration mode of clinker storage space frame (T=0.45s)

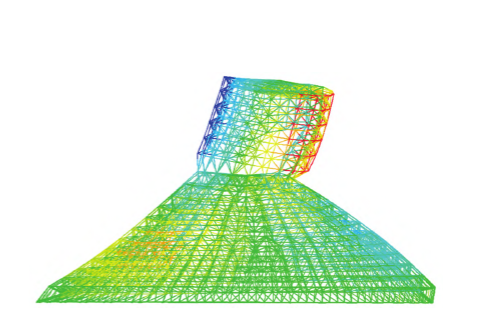

Figure 3 Second vibration mode of clinker storage space frame (T=0.41s)

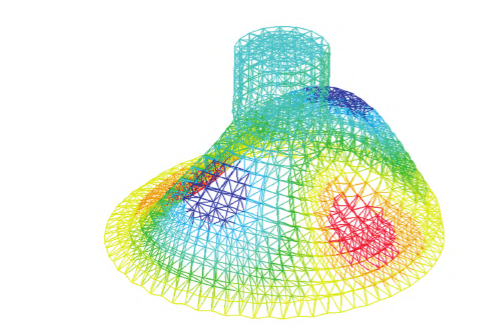

Figure 4 Fifth vibration mode of clinker storage space frame (T=0.31s)

About Us

About Us 2023-10-13

2023-10-13