The newly built coal storage shed in a thermal power plant is a double-layer space frame structure with a closed arch roof of color steel plate. This kind of large arch net structure has excellent rigidity and good integrity and can bear various loads due to the mutual support between the members, so it is suitable for the local windy climate conditions. As the steel structure of the arch space frame is larger, the installation height of the system is higher. Therefore, the installation of the arch space frame structure is the construction focus of this project.

1. Determination of construction content and technology

The main content of the coal shed construction is to install and place the arch steel frame of the new coal shed. The structural form of the steel frame construction is: a double-layer network frame, the node type is a welding ball, the space frame form is put in four Angle cones, and the support form is peripheral support. The span of the network frame is 69m, the length is 120m, the double layer half cylinder shell, the node adopts the welded ball node network frame, the winding; Lower chord, ventral rod; Ball joint, bearing vertical and side plate combination bearing, rod using Q235B and Q345B material, steel ball Q345B steel, the total weight of the arch frame is 240T (including rod, welding ball), the arch height of the space frame is 14.956m. According to the construction site is relatively wide, the ground assembly is easier to ensure the construction progress and safety quality and other factors, determine the installation of the arch space frame using two pieces of ground assembly, the use of hydraulic jacking equipment piecewise jacking, and then high altitude docking construction technology. Due to a long-span arch steel rack is higher, integrally jack-up in place risk is very big. Jack lifting equipment is more, so the arch rack can be divided into two half, south and north to assemble the welding east half dome rack, gradually by hydraulic jack-up in place, then assembling welding of the half part of the vault rack, gradually by hydraulic jack-up in place, Finally, the middle part of the joint welding. There are two steel space frames in total, each weighing about 120T. The jacking area is about 2100m2. It is necessary to calculate the layout of the jacking points and check the force of each jacking point to ensure the safety and reliability of the jacking process. See the diagram below for jacking points.

FIG. 1 Schematic diagram of space frame segment jacking and jacking point

2. Arch space frame construction technology

2.1 Overall construction technology

According to the situation of the site and the geometry of the space frame, the space frame adopts the installation method of assembling two sections on the ground and then docking at a high altitude to form a whole. First, the 9-16 axis space frame is assembled on the ground and jacked in place. Then, the 1-8 axis space frame is assembled on the ground and jacked in place. After the two frames are respectively in place, they are butt connected at high altitudes.

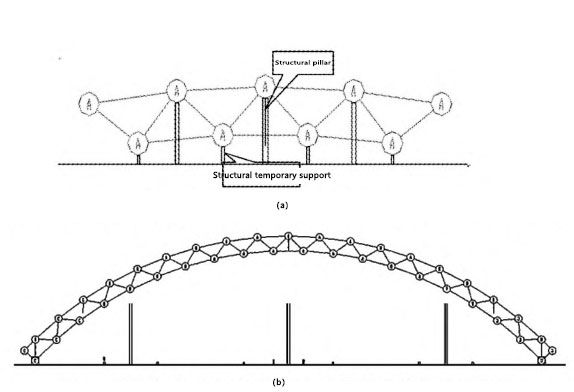

2.2 Assembly and jacking process of each piece

According to the span and camber of a single steel structure of the space frame, each steel structure on-site needs to be assembled four 4 times and jacked four 4 times. Due to the change of jacking point, during the jacking process of a single steel structure, the jacking strut will also change the position of the jacking point twice. Special attention should be paid to the movement of the jacking pillar. First, the assembled space frame should be placed on the floor brick support pier as a whole, and then the jack and jacking frame should be manually removed one by one and transported to the next jacking position for assembly. Specific steps are as follows: single common initial across the assembled – common rack first top up 2.4 m – 2 batch of assembled – 2 batches finished assemble the rack fell on the piers to jack-up pillar shift, the second top – third assembled – single common rack on both sides of the overall fall on the ground brick piers – jack-up pillar shift – the third top – fourth assembled – top liters pillar unloading, The space frame falls into the support. The schematic diagram of the installation process of a single truss is as follows:

FIG. 2 Schematic diagram of a single initial span assembly and supporting structure

3. Jacking process

Jacking process construction channel → removal of debris in and around the jacking range → installation of jacking support and equipment → reinforcement of steel frame → accurate understanding of local weather conditions during the jacking period → acceptance before jacking → beginning of jacking → stop after steel frame jacking to design elevation higher than 0.5m Set the cable wind rope and the original structure concrete column to pull together → install the steel frame support → the steel frame falls back → test, record, analyze and draw conclusions on the data of the steel frame installation → remove the jacking support after the steel frame installation is qualified.

About Us

About Us 2022-10-11

2022-10-11