Clinker is a crucial raw material in the production of cement. It is produced by heating limestone and other materials to high temperatures in a kiln, resulting in small, hard nodules known as clinker. The storage of clinker is an essential part of cement production, and an effective clinker storage shed design is essential to protecting the product from the elements.

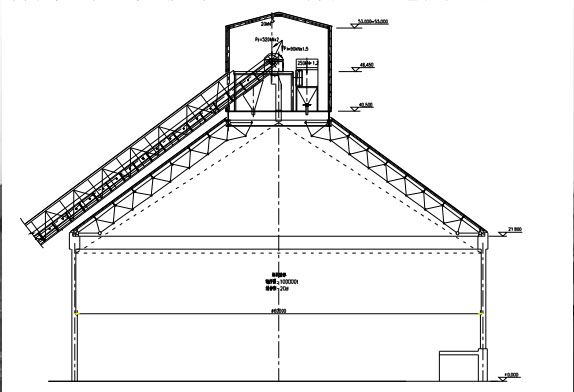

The clinker storage dome shed is a large-diameter warehouse system for storing cement clinker in the new dry process cement production line, A dome-Shaped Design is very popular for clinker storage sheds, this design offers many advantages over traditional flat storage and silos because the dome’s double-curved shape makes it incredibly robust and versatile. This design also allows for more vertical storage space and provides an excellent foundation for heavy loads. as shown in Figure 1. The bottom is a concrete silo structure, and the top of the silo is a steel structure roof and a silo roof. The cement clinker dome shed is transported from the kiln head to the top of the clinker silo through the zipper machine in the steel corridor and then unloaded from the top of the silo. Drop into the library for storage. There are two common structural forms for the roof steel structure: steel truss structure and steel space frame structure. Due to a large amount of steel used in the steel truss scheme, the difficulty in installation and construction, and the large load on the reservoir wall, it has rarely been used in practical projects at present.

Figure 1 Clinker warehouse

1. Selection of steel space frame structure

The process conditions of the steel structure space frame on the top of the clinker dome storage shed system are shown in Figure 2. According to the technological conditions, the roof space frame of the clinker storage shed adopts the shape of a round table and is placed on the ring beam of the concrete silo wall, with an elevation of about 26m. The space frame on the top of the warehouse adopts a double-layer favorable quadrangular pyramid structure with bolt ball joints. There are 48 supports in the lower part of the space frame, the diameter of the center of the supports is 60m, the diameter of the upper platform is 15m, the height of the whole space frame is 17.0m, the thickness is 2.0m, the upper part of the space frame is equipped with a steel platform, which is composed of H-shaped steel beams, and the top elevation is 44.70m, supported by 16 fulcrums on the roof space frame.

Fig.2 Condition diagram of a clinker storage shed

The spatial structure design software 3D3S is used for static analysis and dynamic analysis of the design.

2. Static analysis results

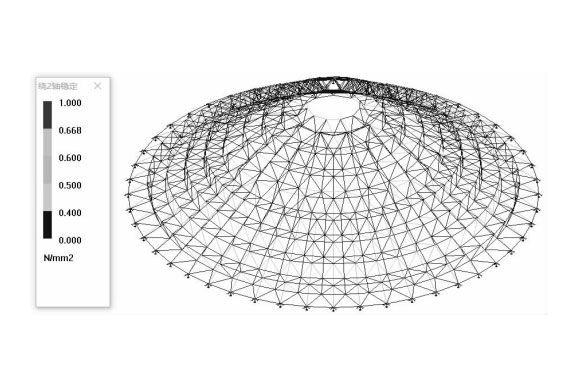

The minimum rod section of the space frame is 75.5×3.75, and the maximum area is 245×16. The stress cloud diagram of the rod is shown in Figure 3, and the total steel consumption is about 240t. The maximum vertical displacement position of the model is the action point of the zipper machine, and the value is 44mm (1/1364<1/400), which meets the specifications and usage requirements. The maximum design value of the support reaction force is 370kN vertically and 130kN radially horizontally.

Fig.3 Space frame dynamic analysis results

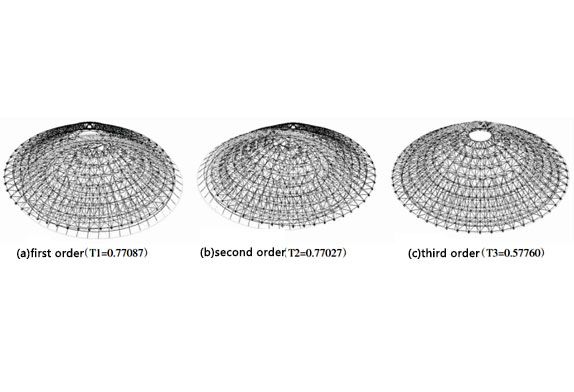

The modal analysis of the space frame is carried out, and the first 30 vibration modes of the structure are extracted to ensure that the mass participation coefficients in both horizontal directions are greater than 90%. The period and mode shapes of the first three orders are shown in Figure 4. The frequency of the structure is relatively dense. The first two order modes are dominated by horizontal translation, and the third order mode is dominated by torsion, and the structural stiffness is relatively large.

Fig.4 The first 3 vibration modes of the space frame

The space structure has been widely used in industrial and civil buildings. Compared with the ordinary roof space frame structure, the roof space frame structure of the clinker silo has a larger vertical load and temperature load, and the influence of equipment vibration load needs to be considered. Design is difficult.

In conclusion, clinker storage shed design is essential to the production of high-quality cement. The choice of a dome-shaped structure, implementation of dust suppression systems, and customized conversions and refurbishments ensure that clinker is well-protected and that the storage operation runs with maximum efficiency. With the right design, clinker storage sheds can provide a long-lasting and reliable solution for cement production.

About Us

About Us 2022-10-08

2022-10-08