1. Prefab Stadium Project Overview

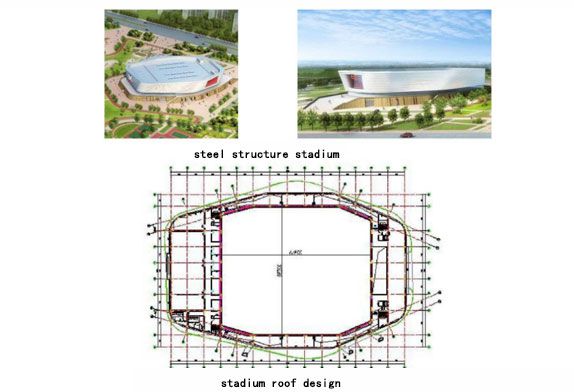

The National Fitness Activity Center mainly includes “two gymnasiums and two games” including gymnasiums, swimming pools, stadiums, and outdoor activity venues. Among them, the gymnasium is a Grade B gymnasium (as shown in Figure 1), with a construction area of 13550m², 3 floors above ground, and a building height of 19.95m. The main body of the gymnasium adopts a reinforced concrete frame structure, the large-span competition space in the middle adopts a spatial steel structure, and the projection is an irregular octagon with a long axis of 67.8m, a short axis of 58.2m (plan view shown in Figure 1).

FIG.1 prefab stadium construction

2. Comparison and selection of stadium roofing methods

According to the characteristics of this venue, combined with several commonly used roofing methods, this project proposes three roofing methods: light metal roof, steel frame light plate roof, and cast-in-place concrete roof.

Light metal roof: Light roof is generally used as the roof envelope for large-span steel structure roofs. The load is light, which can effectively save the amount of steel used, and the seismic effect is small, and the roof shape is beautiful. However, the cost of light roofing is high, there are wind and water leakage problems, and the later maintenance costs are high.

Steel frame light plate roof: In recent years, the steel frame light roof panel (sky base plate) has been widely promoted in China. The roof panel maintains the advantages of high safety and long service life of traditional reinforced concrete components, and the load is lighter than traditional reinforced concrete. High quality and fast construction speed.

Cast-in-place concrete roof: Reinforced concrete roof has mature construction technology, low cost, and easy maintenance in the later period. The three roofing methods have their own advantages and disadvantages. According to the characteristics of the venue, trusses were selected as the structural form of the steel roof..

Table 1 Economic comparison of different roofing practices

|

|

|

Scheme 1: |

Scheme 2 : Lightweight plate with steel frame |

Scheme 3 : Cast in place concrete plate

|

|

The roof dead load value |

0.8KN/M2 |

3.0KN/M2 |

5.3KN/M2 |

|

|

Roofing cost (Yuan/m2) |

Roofing method |

Molded steel plate |

Lightweight floor slab with steel frame |

Cast-in-place steel reinforced concrete floor slab |

|

Cost (Yuan/m2) |

776.6 |

569 |

608 |

|

|

Purlin/secondary beam cost (yuan /m2) |

The steel amount(kg/m2) |

14.8 |

16.3 |

18 |

|

Cost(元/m2) |

133 |

147 |

162 |

|

|

The steel structure cost (Yuan /m2) |

Steel amount(kg/m2) |

31 |

57 |

71 |

|

Cost (元/m2) |

294 |

536 |

674 |

|

|

Total cost (元/m2) |

|

1203 |

1252 |

1444 |

As can be seen from the above table, the total cost of a light metal roof is slightly lower than 5% of the cost of light steel skeleton plate when considering the change of steel volume brought by roof load on the roof structure. However, both the builder and the architect of this project consider that architects do not pursue the effect of the fifth facade, and consider the cost of later construction and maintenance. After a comprehensive comparison, they finally choose a light steel skeleton plate as the roofing method of this project. At the same time to achieve construction, convenient maintenance, and good economic effect.

3. The proposal for the stadium roof steel structure design scheme

Combined with the characteristics of this prefabricated stadium project, three structural schemes of string beam, one-way truss, and space frame are proposed for analysis and comparison.

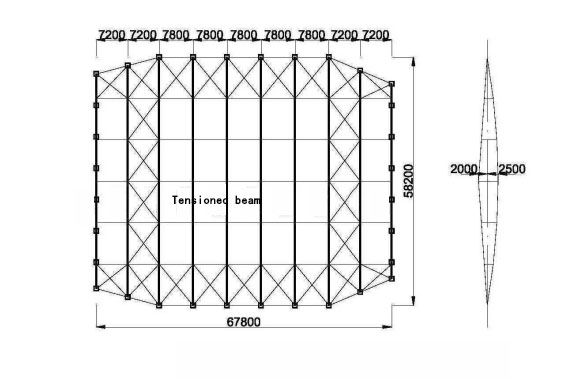

(1) Stranded beam scheme The stretched beam scheme is a plane-bearing structure composed of broken-line steel beams, lower chord cables, and struts. It exerts the characteristics of high tensile strength of steel cables and good compressive performance of upper chord broken-line structures. The force is reasonable and can reach a large span.

In this project, 8 string beams + 2 steel beams are set along the north-south direction. The span of the string beams is 58.2m, the spacing is 7.2m/7.8m, the height of the single string beam is 2m, and the sag is 2.5m. A total of 5 struts are set, and the upper string is supported on the concrete. top of the column. In the other direction, the roof structure is connected into a whole by connecting rods, see Figure 2 for details.

FIG.2 Tensioned beam

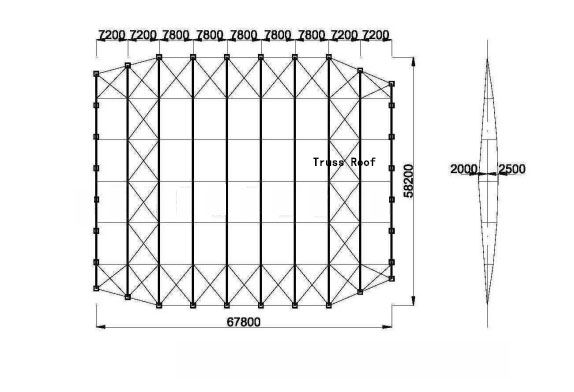

(2)The one-way truss scheme considers the long-span spatial scope of the project’s inner field. The column network takes the east-west (long) axis as the symmetric axis in one direction, and the roof is along the north-south (short) two-way slope of 5%. In the one-way truss scheme with the span direction as the direction, the force is mainly transmitted along the north-south direction, and the other direction passes through, and the connecting rods connect the roof structure into a whole. A total of 8 trusses + 2 steel beams are set up. The span of the truss is 58.2m, the spacing is 7.2m/7.8m, the height of the truss is 3.0 m~4, and the gradient is 455m. The upper chord is supported on the top of the concrete column.

FIG.3 steel truss roof

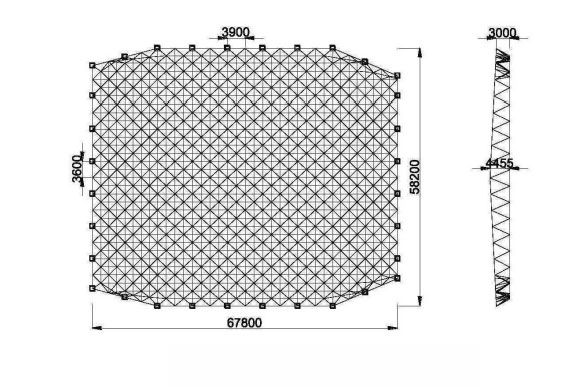

(3)space frame scheme The space frame is selected as a positive quadrangular pyramid space frame, the space frame size is 3.6×3.9m, the slope is found in one direction according to the 5% slope, the height of the space frame is 3.0m~4.455m, and the space frame as a whole is along the east-west direction ( The longitudinal axis is symmetrical, and the peripheral upper chord is supported on the surrounding concrete columns. The plan elevation of the space frame is shown in Figure 4.

MIDAS was used to establish the three scheme models respectively, and statically determinate constraints were adopted as the constraint conditions.

Table 2 Comparison of calculation results of three structural schemes

|

|

Scheme 1: : Beam String Structure Scheme |

Scheme 2: Truss Structure Scheme |

Scheme 3: Space Frame Structure Scheme |

|

Deflection( mm ) |

237.0 |

173.9 |

253.6 |

|

Force of reaction ( kN ) |

1179 |

1061 |

1791 |

|

The steel amount ( kg /m2 ) |

54.4 |

49.5 |

41.9 |

FIG.4 space frame structure

Through the comparison of the above table, it can be seen that the space frame plan and the truss plan have advantages in terms of steel consumption and deflection respectively. Considering that the roof is a light steel skeleton plate, it has stricter requirements on deflection, and the truss plan is selected as the project house. The cover scheme and the support of this scheme is evenly stressed and the amount of steel used is moderate, which has great comprehensive advantages.

Based on the project scale and construction conditions, this project conducts a selection analysis on the roofing method and roof structure form, and draws the following conclusions:

(1)Light roofing is a common form of large-span steel structure roofing, and the cost of simple roofing is relatively high, but comprehensive consideration Due to factors such as the amount of steel used, the force on the concrete column, and the design of the bearing, the light roof and long-span roof have high economical efficiency.

(2)The comprehensive cost of the long-span steel-framed light-span roof and the light-span long-span roof is 4% higher. Considering the construction and post-maintenance level of the project construction site, the steel-framed light-span roof is preferred for this project.

(3) The structural form of the roof has a great influence on the deflection, the amount of steel used, and the reaction force of the support: the amount of steel used for the space frame structure is the lowest, but for the span of this project and the selected roofing method, the deflection value is the largest The truss beam structure is light and simple, but the amount of steel used is high, and the construction process is complicated. The cost of structural components such as cables and struts is higher than that of ordinary steel, which is not suitable for this project. The truss structure can effectively control the structural deflection, and the amount of steel used is moderate. , and the reaction force is uniform, the support is easy to process, and it becomes the best choice for this project.

About Us

About Us 2023-02-10

2023-02-10