1. Metal Building For Exhibitions Project Overview

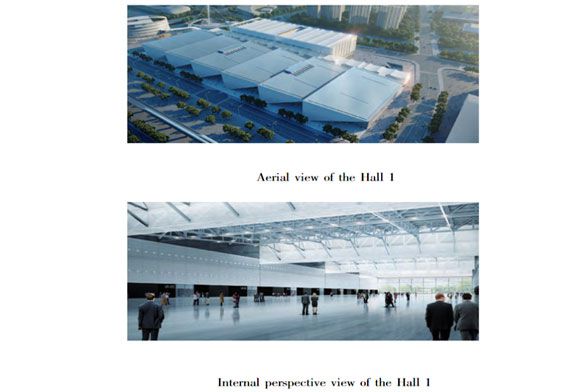

The first phase of an international convention and exhibition hall has a total construction area of about 173,500 square meters and a total of 2,500 booths, mainly composed of a No. 1 exhibition hall, a No. 2 multi-functional exhibition hall, and a conference center. The No. 1 exhibition hall does not have a basement, with a total construction area of 48,000 m² on the ground, a building height of 27m, and a plane projection size of 380m×112m. The super-large exhibition hall has a column-free span of 72m and a clear height of 16m, and three movable partitions are set at the 8-axis, 2-axis, and 3-axis to meet the flexible operation requirements of the super-large metal building exhibition hall that can be divided and combined. The architectural plan of the exhibition hall incorporates the continuous and scattered roof elements of the water town buildings. The roofs of 6 similar units are inclined from east to west and are rhythmically staggered, with a roof slope of 9.5% and a vertically staggered height of 6m

Prefabricated steel hall for displays

Prefabricated steel hall for displays

2 . Features of prefabricated steel hall for displays

1) The No. 1 exhibition hall has a rhythmic staggered roof shape. The super-large exhibition hall has a column-free span of 72m. The shape is irregular and the span is large. The design and construction of the main structure and roof system are difficult.

2) The No. 1 exhibition hall is required to start construction in February 2019, and it will be put into use in September of that year, and the construction period is extremely tight.

3) The project is constructed in the EPC mode and is implemented by a consortium composed of domestic leading design companies and general contractors of prefabricated steel structure buildings. Under the conditions of a tight construction period, how to use the advantages of EPC and give full play to the synergy between design and construction, as well as between professions and professions, is the key to the on-time delivery of the project.

3. The exhibition room’s main structure and roof system design

Under the EPC mode, the construction period becomes the same responsibility of the design and construction subjects, and the construction subjects can fully participate in the negotiation of the design plan. According to the actual situation of the project with a tight construction period, the general contracting department set up a design management team to fully participate in the design process, using the basic engineering experience that the completion of the main body is the premise of the development of the seven major divisions, and the water closure of the roof is the basis for the interior decoration. The research and comparison of the roof system design scheme is the focus of early design management.

According to the materials used for the exhibition room main structure, domestic large-scale exhibition buildings generally have two schemes: concrete main building + steel structure roof and all-steel structure. From the perspective of the construction period of the main structure, the latter is generally more than 50% shorter than the former, while the latter is conducive to The main body of the project taking advantage of its own resources to speed up the construction progress. Therefore, the main structure of this project adopts an all-steel structure scheme, and the roof is equipped with a thermoplastic polyolefin waterproofing membrane (TPO) + vertical seam aluminum-magnesium-manganese plate double-layer waterproof metal roofing system.

In large-scale public metal building construction projects, large-span steel structures and metal roofing systems are twin brothers. Because they belong to two sub-sectors, there is a general disconnect between professional design and sub-professional construction, and design and construction are out of touch. Conducive to construction period and cost control. This project takes advantage of the favorable conditions of the EPC model to implement in-depth collaboration between the design and construction entities, and adopts an integrated design for the large-span steel structure-metal roof system, which reduces the construction difficulty of the large-span steel structure-metal roof system, improves the construction work efficiency, and greatly shortens the time. construction period. This paper focuses on the two aspects of roof modeling and structure integration design, roof structure and structure integration design.

4 Integrated design of Steel-framed commercial showroom roof shape and structure

4.1 Comparison and selection of commercial showroom roof structure schemes

4.1.1

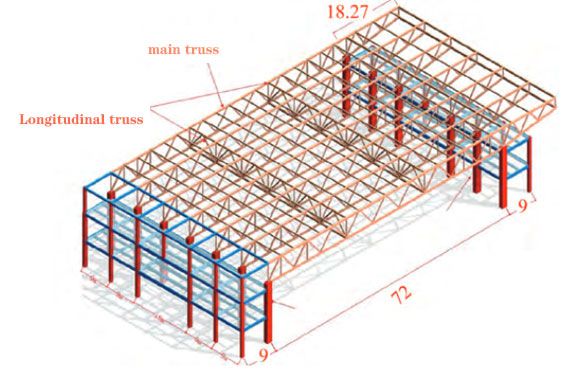

Option 1: Type finding of the commercial showroom roof secondary structure, the roof steel structure is in the shape of a flat plate, and a plane truss structure system is used. The main trusses are arranged along the span direction, and the truss spacing is 9m. towards stability. For the metal roof, a secondary structure is set on the upper part of the steel structure to find a slope, and the maximum overhead height is 5.45m. The roof system is laid on the upper surface of the overhead secondary structure.

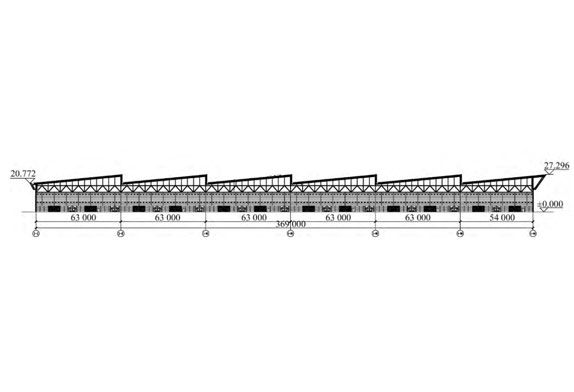

Vertical section of scheme 1

Local steel structure effect diagram of scheme 1

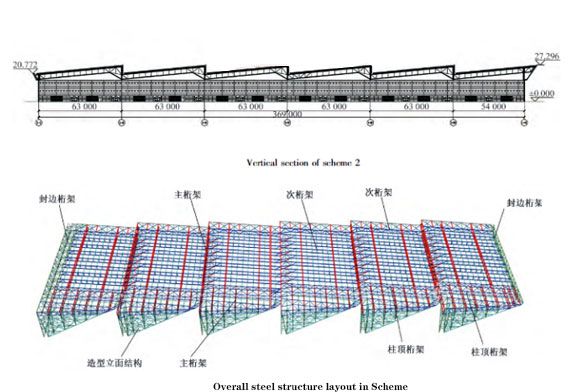

4.1.2 Scheme 2: Finding the shape of the commercial showroom main steel structure The roof shape of the roof steel structure is designed to fit the rhythmic undulation, and the metal roof is directly laid on the finished surface of the roof steel structure.

The roof steel structure adopts a plane truss structure system, which is divided into 6 units according to the undulation of the roof, and is connected with the inverted tapered grid structure of the streamers as a whole. The main trusses of the roof are arranged along the span direction and rigidly connected to the frame columns at both ends, with a span of 72m. Among them, 10m three-chord main trusses are arranged in the staggered parts of each unit, and two 4m-high two-chord plane trusses are arranged in each unit, and the distance between the main trusses is 18m. /21m. Vertically to the main truss, a 4m-high empty-web secondary truss is arranged, the interval between the secondary trusses is 9m, and the upper chord is arranged with dense secondary beams, and the roof is divided into 4.5m×9m space truss.

4.1.3 Scheme comparison See Table 1 for the comparison of the two schemes. From the comparison in Table 1, it can be seen that the construction of the foundation and steel structure in Scheme 1 is relatively convenient, but it greatly increases the workload of the substructure of the roof, and needs to be sheltered by the ceiling, so the economy and construction efficiency are not good; although the construction of foundation and steel structure in Scheme 2 The technical difficulty has increased slightly, but the high-altitude operation of the metal roof has been greatly reduced, which is conducive to the advance of the roof water closure time, and the need for no suspended ceiling reduces the workload of interior installation, which is beneficial to the overall construction period of the project, so the final choice 2.

|

Scheme |

Advantage |

Disadvantage |

|

1 |

1)The exhibition hall roof steel structure layout is regular, the truss height is small, the section type is few, and the processing and the field installation is relatively convenient; |

1)The secondary structure of the roof does not participate in the main structure work, component design is mainly controlled by stability, structural efficiency is low, self-heavy, the main and secondary structure combined with the amount of steel up to 168kg/m2, uneconomic; |

|

2 |

To improve the overall rigidity and structural efficiency of the roof, a huge main truss is arranged by using the staggered platform. |

1) The height of the three-string main truss is 10m, with a single mass of 160t, making it difficult to construct; |

4.2 Structural analysis Due to the large fluctuations of the structure in Scheme 2, the stiffness distribution of the truss is not uniform, and there is a sudden change in the force transmission path in the longitudinal direction. In order to verify the reliability of the structural scheme, the finite element method is used to calculate and analyze the performance indicators of the structural scheme.

5 Integrated design of exhibition building roof structure

For the main steel structure type finding scheme, in order to further improve the construction efficiency of the roof system, the straight-laid large-span bottom plate and the purlin system are used to separate the load-bearing structure. The advantages are as follows:

1) The bottom plate support cold-formed channel steel is easy to make, and can be directly integrated into the roof steel structure for integrated processing and integrated hoisting. After the steel structure construction is completed, the roof bottom plate can be directly laid, and the construction process of the roof system is further reduced. The TPO water closing time can be greatly advanced, which is very beneficial to the overall construction period control of the project; the large-span bottom plate is directly laid on the upper surface of the steel beam through the cold-formed channel steel, and the steel beam changes from bearing several concentrated loads to bear uniformly distributed loads, according to this force The model is analyzed and checked, and the specifications of the roof steel beam components have not changed.

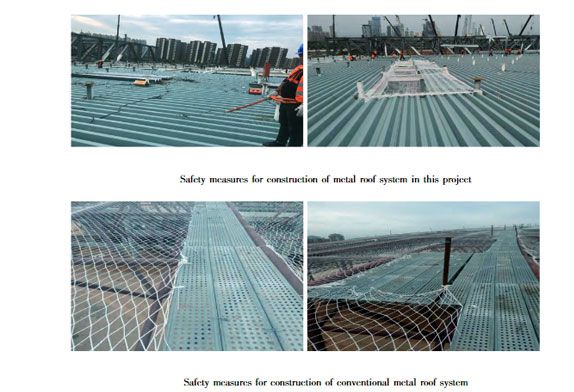

2) After the steel structure construction is completed, the roof bottom plate is directly laid to form a reliable construction platform. Compared with the full paved walkway and horizontal safety net after the construction of the conventional metal roof system, the construction safety is greatly improved, which is very beneficial to improve the construction efficiency. The investment in safety measures has been greatly reduced, which is beneficial to the control of construction costs.

3) Although the amount of steel used is slightly increased, the integration of the supporting components of the exhibition building roof system and the main steel components is realized, the construction process of the roof system is further reduced, and the construction safety is greatly improved, which is conducive to the improvement of the construction efficiency of the roof system and the early closure of the roof system. Water is beneficial to the overall construction period and cost control of the project.

About Us

About Us 2023-03-27

2023-03-27