4.9、Unloading

After the space frame support is installed, the overall structure is pre-unloaded (leave a 3~5mm gap between the bottom surface of the support and the embedded parts), and the unloading is completed after the space frame axis is adjusted to meet the design requirements. The unloading is controlled synchronously by the computer, and the unloading is 20mm each time.

After the adjustment of the space frame axis is completed, the bottom surface of the support is 3~5mm away from the embedded parts, and the unloading starts step by step, first unloading the small gap, and then unloading the large gap. During the unloading process, all jacking points should be unloaded synchronously and slowly, and strictly controlled according to the range of unloading deflection value given by the design. When an abnormality occurs, the oil cylinder should be locked immediately, and the unloading can only be continued after analyzing and eliminating hidden dangers. Walk through the lower part. After the unloading is completed, the space frame should be continuously and regularly monitored, mainly to monitor the deformation of the space frame in the area with a large span and to make statistics on the deformation development law of the monitoring points.

4.10、Removal of jacking device

When removing the jacking device, firstly the upper bracket is stressed, the cylinder piston rod is retracted until no force is applied, and the cross bar (forced rod) is moved down. out, and move the lower bracket to the next support frame, so that the lower bracket is stressed and the upper bracket is not stressed, and a section of the support frame is removed. Proceed in sequence, and remove the supporting equipment section by section until it is completely removed.

5、Safeguards

5.1、Reinforcement of rods

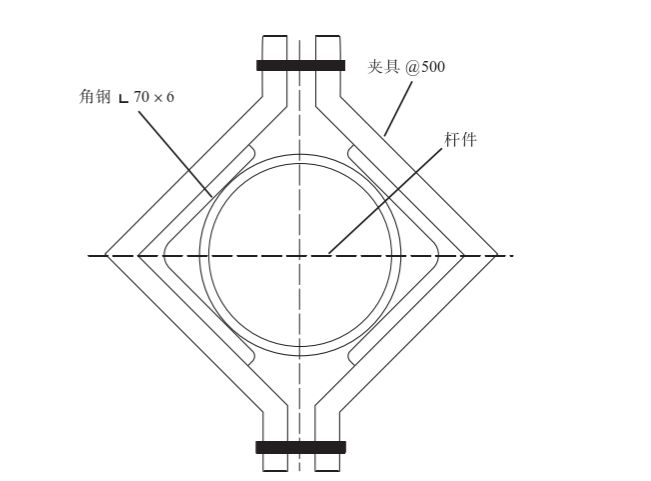

In view of the overstressed part of the space frame rods identified in the construction simulation, cloth strips are used to bind and mark the middle of the rods, and a wall-attached hugging type circular rod anti-compression reinforcement device is designed, and the angle steel is attached to the wall before the formal jacking Reinforced with hoops.

During the jacking process, continue to observe the deformation of this part of the rod, stop the jacking immediately if deformation occurs, lock the main jacking cylinder group through the jacking control program, analyze the cause of the deformation, and continue jacking after eliminating hidden dangers (Figure 4 ).

Figure 4 Schematic diagram of rod reinforcement device

5.2、Treatment measures that support falls on different types of foundations

(1) When the support falls on the ground where the bearing capacity of the foundation meets the requirements, place a steel plate subgrade box with a thickness of 120mm on the foundation, lay a stone cushion layer under the subgrade box, and vibrate the cushion layer with a flat vibrator to make it compact and smooth. Put the standard section of the support point on the subgrade box as the basic point for jacking and then carry out the jacking operation.

(2) When the support falls on the ground where the bearing capacity of the foundation does not meet the requirements, set up a concrete foundation at the position of the support point. After the strength of the concrete reaches more than 75%, place a steel plate on the top of the concrete foundation, and then carry out the layout and construction of the support point.

(3) When the support falls on the structural concrete column, no reinforcement measures are required, and the construction load can be transmitted downward from the structure to the foundation part.

(4) When the support falls on the structural concrete beam, use standard joints to set steel plates above and below the position of the ground beam on the first floor for backing up to ensure that the force is transmitted to the concrete ground beam on the first floor.

(5) When the support falls on the structural concrete slab, first carry out the lower foundation treatment, excavate the foundation groove on the indoor foundation, backfill the gravel in the groove, and vibrate it compactly, and use 4 square wooden bundles on the gravel Into a combined sleeper. Set steel plates on the combined sleepers to ensure uniform load transfer and prevent settlement. Place the difference-finding joints and jacking standard joints on the steel plates to return to the lower part of the corresponding concrete floor to complete the return.

5.3、Support frame stability control

The jacking construction technology described in this project needs to change the position of the supporting frame, and the frame is high, which is not suitable for the fixed foundation method and the balance counterweight method of the frame stability and reinforcement measures. The traditional ground anchor method is adopted, and the single-hole inclined web The rod is a bracket, which reinforces the stability of the supporting frame. Rigid diagonal braces are added around the frame body of the jacking frame exceeding 6m, and stay cables are added over 10m to achieve the effect of ensuring the safety and stability of the supporting frame.

5.4、space frame horizontal deformation control

In order to ensure that the space frame structure does not undergo horizontal deformation during the post-repairing process, the horizontal positioning of the space frame is precisely adjusted, and the steel strand cable wind rope and the structural ring beam are used as limit cable stays before the final top, and the fixed point is located on the plane space frame In addition, a total of 8 channels are symmetrically set. One end of the cable wind rope is tied to the support frame, and the other end is fixed on the ground anchor. The angle between the support and the ground should be 45°~60°. The horizontal deformation of the space frame can be controlled by adjusting the length of the steel strand wind rope. .

5.5、Construction quality control of rear embedded rods

During the connection of the post-insert rods, all jacking support hydraulic cylinders should be locked, and the stability of the space frame support body should be continuously observed, and the deviation of the support elevation that occurred during the connection of the post-insert rods should be adjusted in time to avoid construction stress solidification.

About Us

About Us 2023-09-18

2023-09-18