1. Skylight Glass Roof Dome Project Overview

Figure.1 Skylight roof glass

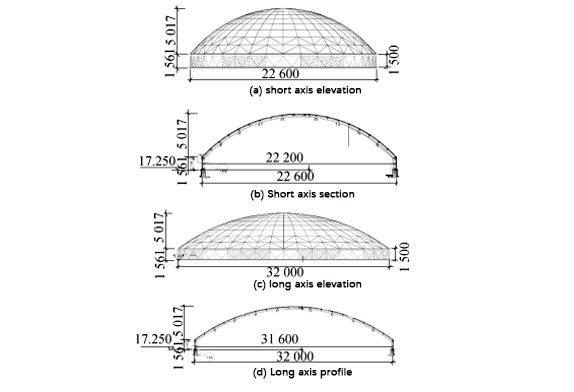

A shopping center has 2 skylight roof glass domes, one is a dome skylight with a span of 30.8m, the other is an oval skylight, its long axis is 32m, and its short axis is 22.6m. The glass dome roof construction is located on the roof of the third floor and the installation height is 15.3m. Because the skylight roof glass domes are inside the building, there is no installation space and no transportation road, which brings great difficulties to the installation; due to the large area, high height, and heavy steel structure of the glass dome building, the single-piece hoisting and installation time is long. The quality is difficult to guarantee; the size and shape of the skylight dome roof vary greatly, so it is not suitable to set up scaffolding as an auxiliary tool for skylight installation.

Focus on the key issues in the glass dome roof construction installation process, such as installation method, installation sequence, etc., and adopt the center operation platform + high-altitude section hoisting + mid-unit unit hoisting and installation method for construction to improve construction production efficiency, ensure construction quality and safety, shorten the construction period, reduce material waste and save glass dome construction costs.

2. Steel Structure Skylight Glass Roof Dome Without Tire frame installation

2.1 Installation principle

BIM technology is used for construction simulation, and finite element software is used to decompose the steel frame of the dome-type steel structure daylighting skylight, and the center of gravity, quality, external dimensions, splicing position, and installation position of the decomposed components are analyzed. Carry out hoisting condition analysis and structural floor bearing capacity analysis based on factors, determine the technical parameters of hoisting equipment and the position of the hoisting point, and set up an operation platform at the center of the circle (the main accessories are standard sections of tower cranes), and add the rest of the outer ring at the lower part of the elliptical arc main beam after the truss, the scaffolding board is laid on the truss as the operation frame, and it is removed after the construction is completed in the later stage. The lifting sequence is to install the cross-shaped main keel supporting members first, then the middle ring members, and finally the symmetrical installation of the remaining keel arc members, which effectively ensures the installation accuracy of the dome-type steel structure skylight roof.

During the skylight dome installation process, the installed and currently installed components are connected by temporary top braces to form a stable triangular self-balancing system. The components are hoisted in place, and the measurement and positioning meet the requirements. After the welding is completed and the acceptance is passed, the hooks are decoupled, and then the next component is installed.

After the installation of the components in the middle ring is completed, the components connected to the middle ring of the dome are symmetrically installed by the tower crane, and then the tireless construction of the steel structure of the daylighting dome is completed.

2.2 Glass Dome Construction technology

Before the installation of the lighting dome, the steel structure should be in-depth designed, so that the steel structure can withstand the load of the construction operation. with this as the background, and then the subsequent construction. Before setting up the center operating platform, make the lighting dome accessories that need to be installed. After erection, firstly hoist the cross-shaped main keel to support members, and then hoist the rest of the support members and arc-shaped members. After welding, check and complete the steel frame, and finish the construction of the steel frame finish paint, and dismantle the platform after installing lighting glass.

2.3 Operation points

2.3.1 Deeping design of steel structure dome roof

The basic design of the steel structure lighting dome is shown in Figure 1. In order to facilitate construction and reduce the amount of work for erecting scaffolding, an operating platform is set up at the center of the circle (the main accessories are standard sections of tower cranes). the rest of the outer ring in the lower part of the elliptic arc main beam truss, laying foot plate on the truss as the operation frame, demolition after the completion of construction.

Figure.2 Skylight roof glass dome building

Before hoisting, it is necessary to deepen the design of the main beam of the steel structure. By adding the lower diagonal support to install the transverse belly rod and tie rod, the working surface is provided for laying the footboard and hanging the visual network in the later period. The additional members are removed after the installation.

2.3.2 Set up the center of the circle operation platform

A steel structure platform is set in the center of the glass dome building, which is used as an operating platform and positioning and fixing the central ring member of the dome. The steel structure platform is erected by standard sections of tower cranes, with an installation height of 22m (10 standard sections and the height of the lighting roof is 23.75m). mainly used for installation of tempered glass, shading curtain, and electrical parts, itself does not bear the load of lighting top.

The entire steel structure truss itself is fixed on the embedded part of the floor, find the control point, level it with a level, and control the placement point after review and confirmation. The foundation of the central lifting support is made of rolled wide-flange H-beam (200mm×200mm×8mm×12mm), which is diamond-shaped, and its ends are connected with the reinforced concrete main beam or column through the embedded parts (the reinforced concrete main beam or column should be Pre-embedded steel plates are reserved). Stiffeners are added to the base nodes connected to the tower crane standard, and the tower crane standard node positioning and base connection.

2.3.3 Fabrication of truss beams

1) Oval dome skylight roof

The use of truss beam construction, and a ϕ100×5 transverse web member is installed at the lower part of each elliptical spherical steel beam, and the main beam and the web member are connected by ϕ80×4 tie rods. The maximum penetration of the truss beam is 1.9t. After all truss beams are hoisted and adjusted and fixed, hang a safety net under the truss beams.

2)Truss beam processing

In order to minimize the high-altitude operation and satisfy the self-stability of the hoisting components, the whole section of the steel beam is hoisted as a whole. It is assembled into a whole section of steel beam at the construction site, which is a hoisting unit. At the same time, in order to facilitate the installation of the top steel structure and the later ring beam, aluminum plate, and glass, the welding part of the truss beam vertical rod and the diagonal stay rod are staggered from the ring beam part. The bottom chord and web of the truss girder are spliced by butt welds. Considering that the span of the truss in the middle of the elliptical atrium is 15m, the arching of the middle part is 20mm. When the deformation of the steel structure exceeds the allowable deviation range after welding, it should be corrected. such as the use of mechanical method to correct the deformation of members, environmental temperature ≥0℃; When using heating windproof for correction, heating should be slow and ≤900° to prevent material from overburning.

2.3.4 Fragmented hoisting of steel structural members

1) Selection of hoisting equipment according to the quality and distance of the processing components, the tower crane installed on site is selected as the main hoisting equipment. Frame installation process size review before hoisting Before the deepened truss is installed, the size should be reviewed before installation to further repair the deformation and defects of the components, and the deformation and defects of the components should be further repaired. In this scheme, a tower crane is used to install the truss. The main structure of the truss is assembled on the ground, so the total mass of the entire structure is calculated during hoisting, and a 2% difficulty coefficient (weld seam) is added to ensure that the mass calculation is not less than the actual value and the safety of selecting tower cranes.

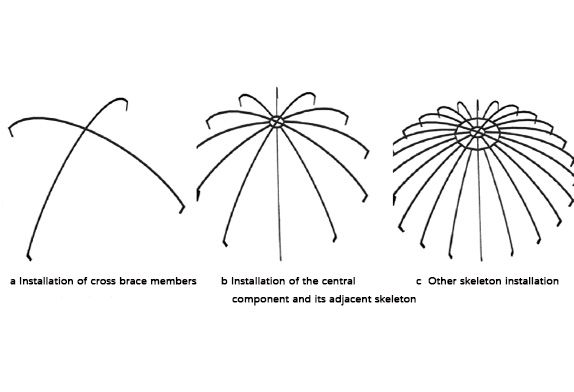

2) the safety of the hoisting order considering the dome structure, the whole arc lighting of the roof truss hoisting elliptic half shaft steel gl11 integral hoisting (2), and then respectively lifting two long axes of the ellipse steel gl1, make the dome to cross, recycling circle welding operation platform, will be central components in place to form a stable system, then, in turn, hoisting gl2 ~ gl10, Until the entire steel beam is lifted. When the steel truss is hoisted, the weight of the short-axle steel beam (full-span lifting) is about 1.4t, the weight of the long-axle steel beam (half-span lifting) is about 1.0t, and only the elliptic short-axle steel beam is full-span lifting, and the rest of the steel beam is half-span lifting. The short-axle steel beam is installed first, and then the long-axle steel beam is installed, and it is used as the support of the rest of the steel beam after installation. The steel beam number is shown in Figure 3,

FIG.3 Skeleton installation process

3) Hoisting in place and fixed-point control before hoisting, the control line during installation should be marked on the surface of the component as the basis for correction. When hoisting, first lift the truss beam about 50cm off the ground, so that the center of the truss beam is aligned with the center of the installation position, and then slowly lift the hook, reoccupy the slip rope rotating roof on the top of embedded parts, to make the hook in place, should be slow to fall hook, And in the roof frame just contact embedded parts of the top brake alignment embedded parts reserved positioning line, and the embedded plate and steel beam head welding temporary fixed, at the same time the verticality correction and the final fixed, roof frame verticality with hanging hammer inspection, at the same time each correction of a steel beam should be connected with the front root beam with the keel and fixed.

About Us

About Us 2022-07-29

2022-07-29