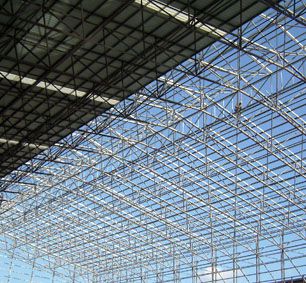

One of the defining features of flat space frames is their ability to span large distances without the need for intermediate supports or columns. This makes them an attractive option for architects and engineers who want to create open spaces with minimal obstruction.

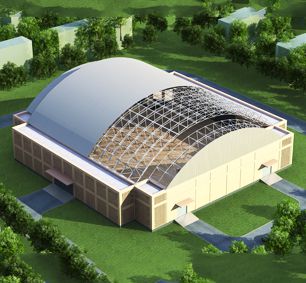

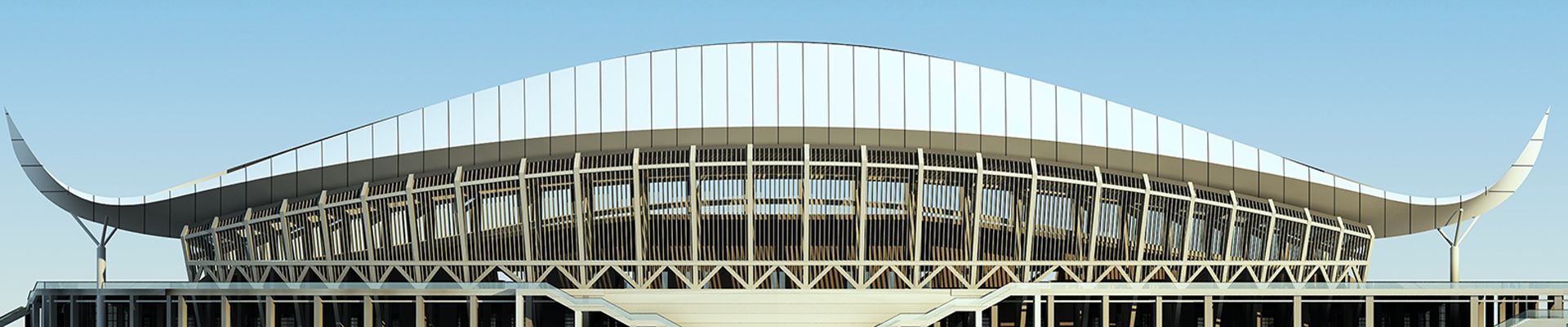

The flat space frame is very flexible, it can be used in rectangles, circles, ovals, sectors and polygons, and other shapes of construction, the appearance is modern, light, magnificent, and very expressive, it’s popular among designers and customers.

Design and Construction:

The design of a flat space frame begins with an analysis of the loads it will need to support. This includes not only the weight of the structure itself, but also any additional loads that will be placed on it during use, such as wind or seismic forces.

Once the loads have been calculated, the size and spacing of the frame members can be determined. Typically, flat space frames are constructed from steel or aluminum, although other materials may be used depending on the specific application.

The members are then connected using a variety of methods, including welding, bolting, and riveting. The connections between members are critical to the performance of the frame, as they must be able to transfer loads between elements and resist bending and twisting forces.

Applications:

Large retail spaces, such as malls and department stores

Exhibition halls and convention centers

Sports arenas and stadiums

Airport terminals and hangars

Industrial buildings, such as warehouses and manufacturing facilities

In addition to their structural benefits, flat space frames can also contribute to the aesthetic appeal of a building. The open, unobstructed spaces they create can be used to showcase artwork, provide natural light, or simply create a sense of grandeur.

Product Category

Product Category

Chat with us

Chat with us

Leave a message

Leave a message

Download

Download