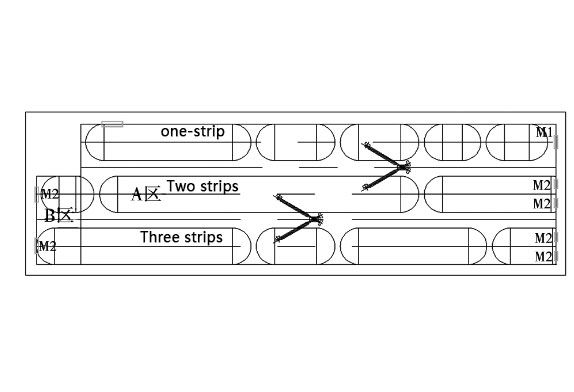

The total closed area of a material warehouse stockyard storage shed is 58240m², and the material warehouse stockyard storage shed area covers a total of 3 original material strips, including two stacker and reclaimer tracks and 3 stacker and reclaimers. The new closed material shed is divided into two areas. The main material steel structure shed (area A) has a length of 430m and a span of 119.8m. The auxiliary material shed (area B) has a length of 40m and a span of 80m. Areas A and B can communicate with each other at the junction. The roofs are all steel pipe three-dimensional structural steel roof truss designs. The structural line model is established based on tangent three-centered circles. The maximum span of the structural support is 119.8m, and the building plane is approximately rectangular, as shown in Figure 1.

Figure 1 Building floor plan

The stockyard warehouse storage shed design service life of the project is 50 years, the safety level is Class II, and the seismic fortification category is the standard fortification category. The permanent load directly borne by the upper chord of the structure is considered to be 0.25kN/m2, the roof live load is 0.50KN/m2, the wind load is 0.40KN/m2, and the snow load is 0.4KN/m2. +26°C~-26°C. The seismic fortification intensity is 7 degrees (0.10g), and the designed earthquakes are grouped into the second group.

Shed Structural features

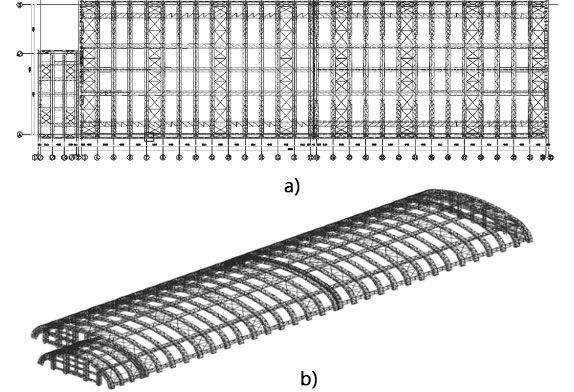

Considering that the maximum span of the structure is 119.8m, which belongs to a large-span truss roof structure, the use of effective means to calculate the overall stability of the structure to check the static analysis results has become an important part of the structural design of the project. According to the static calculation and comparison, it is finally determined that the longitudinal spacing of the three-dimensional trusses in areas A and B is divided into 11m and 15m, which is more economical and reasonable in terms of steel consumption. In order to reduce the adverse effect of temperature on the structure and consider the favorable layout of the structure for earthquake resistance, two structural joints were set up to divide the entire roof into three units. Secondary trusses and tie rods, cross bracing, stay cables and other components are arranged longitudinally to support the stability of the main truss out of the plane. The main chord and its web material are Q345B, and the three-dimensional main truss and sub-truss sections of the standard product are all inverted triangles, that is, two upper chords and one lower chord. The three-dimensional main truss section of the gable side is rectangular, that is, two chords for the upper and lower chords. The nodes all adopt intersecting welding nodes, and local welding ball nodes are used. The bearing node adopts a fixed spherical hinge bearing. The plan layout of the structure is shown in Figure 2-a, and the schematic diagram of the axial side of the structure is shown in Figure 2-b.

Figure 2 a (Structural Plan Layout )and b (Schematic diagram of the shaft side of the structure)

About Us

About Us 2022-08-22

2022-08-22