4 Membrane Structure Canopy Design

The design of membrane structure mainly includes body shape design, initial equilibrium shape analysis, load analysis and shearing analysis. The body design is used to determine the building plane shape and size, three-dimensional shape, headroom volume, coordinates of each control point, structure type, and selection of suitable membrane materials and construction plan. Through initial equilibrium shape analysis (also known as shape finding analysis), it is determined that the shape of the membrane surface must ultimately meet certain boundary conditions and pre-stress conditions for mechanical equilibrium; through load analysis (mainly wind and snow loads), the deformation and stress of the structure are accurately calculated, and the initial pre-tension in the cables and membrane are determined; shear analysis is to consider how to cut the three-dimensional non-expandable spatial surface formed through shape finding analysis by cutting the two-dimensional material, and to tension it into the desired shape. This is the most critical technical problem in membrane structure engineering.

5 Problems to be noted in the design of canopy

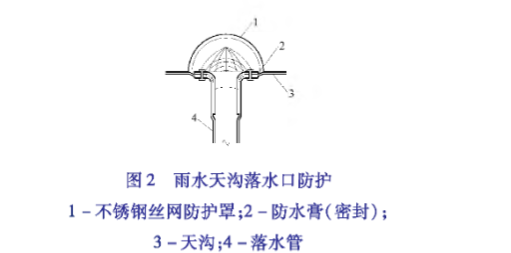

5.1 Roof drainage canopy rainwater gutter should be set up at both ends of the overflow, so that when the amount of rainwater or downpipe drainage is obstructed, it can drain through the overflow without rainwater roaming out of the gutter and disorderly flow on the roof. Canopy rain gutter easy to accumulate dust and leaves, with rainwater rushing around the water outlet, if the water outlet is not protected, leaves are easy to be brought into. When the rain is not large enough to wash away the amount of water necessary for leaves, leaves will be stuck in the downspout turning elbow and deposited with dust, which will form poor drainage or even serious blockage in the long run. Therefore, we should pay attention to the design of protective measures for the gutter downspout, such as the installation of stainless steel wire mesh cover for protection (see Figure 2). At present, the canopy water pipe is usually set in the reinforced concrete column or between the column and the decorative plate, which is conducive to the beauty of the image, but because the ground in the refueling operation area is not suitable for the installation of inspection wells, in later use once the water pipe is blocked, it is impossible to unblock. Therefore, when the canopy is close to the station house, as far as possible – the water collection cross pipe laid along the grid or steel beam is led to the station house surface for centralized drainage, so as to facilitate the later maintenance or replacement of drainage pipes.

5.2 Canopy ceiling

The space frame canopy also reveals many shortcomings after using for a period of time: one, more exposed rods appear intricate and dazzling, the visual effect is poor. Secondly, the net frame needs to be repainted to prevent corrosion after the accumulation of ash, discoloration and rust, and the efficiency of mechanical spraying is low; if painted by hand, the labor intensity is great.

Based on the overall image of the need, many gas stations on the space frame or light steel structure canopy ceiling decoration, to solve the above-mentioned problems. As the ceiling and the surrounding gable and roof constitute a space similar to a boring roof; although the canopy is usually higher than 4.5m and not in the fire and explosion hazard area of the fuel tank under the dispenser or travel lane, but in this space where it is thought that there will be no oil vapor accumulation in the boring roof, not only are the mesh frame rods or light steel structures hidden, but also have the drainage gutter of the canopy, many lighting lines and embedded lamps; when the metal roofing or guttering due to long-term use of rust and corrosion and the formation of rainwater leakage and poor ventilation due to space closure, will make the metal components of the canopy in the boring roof often in a damp state and accelerate its corrosion. And because of the shelter of the ceiling, it is not easy to check the corrosion of metal components, once the corrosion is difficult to be found in time, so it is recommended not to set up a ceiling as far as possible.

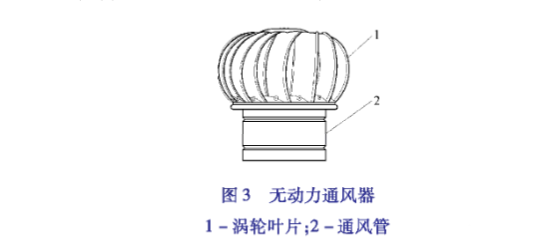

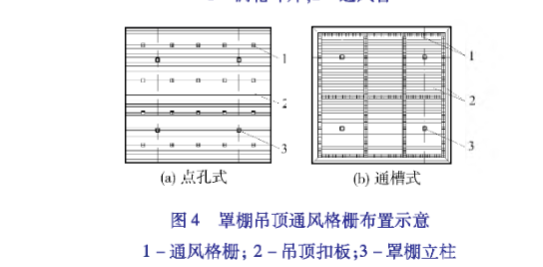

Due to special environmental requirements must be set up ceiling, can be installed in the shed roof a certain number of non-powered ventilator (see Figure 3) and in the ceiling set 5% ~ 10% area ratio of ventilation grille (see Figure 4), the use of air convection principle, the air flow in any parallel direction to accelerate and transform into vertical flow from the bottom up, strengthen the ventilation in the boring roof to avoid and reduce the corrosion of steel structures. When this method is adopted, the ventilation grille can be arranged as point-hole type or through-slot type depending on the ventilation intensity requirements, and the top and bottom positions of the powerless ventilator of the shed roof and the ventilation grille of the suspended ceiling are staggered to meet the performance requirements of the powerless ventilator and improve the ventilation efficiency. Such treatment method is especially suitable for gas stations in rainy environments and coastal areas with high air humidity, and its effect of reducing the corrosion of the steel structure inside the stifling roof of the canopy is also more obvious.

About Us

About Us 2023-06-19

2023-06-19