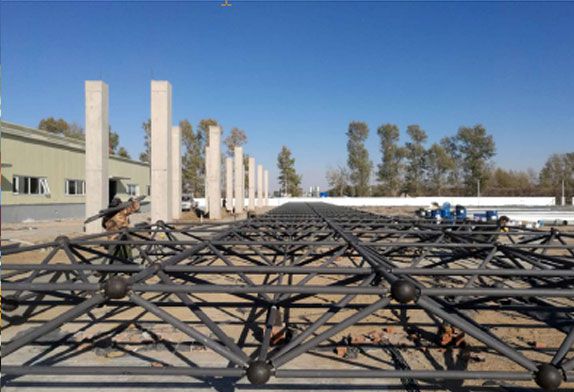

Gas station canopy design is generally flat type, the steel structure space frame canopy of the gas filling station and gas station has the characteristics of long span, many spatial nodes, poor stability, etc., and the construction efficiency is low and the construction difficulty is great, which seriously affects the construction progress. In this paper, the construction method of steel structure space frame canopy and integral lifting is adopted. The unit extension bulk method is used on the ground, extending along with the reference space frame to both sides, and extending in this installation sequence until the entire space frame is assembled. According to the shape, center of gravity, and technological requirements of the steel structure space frame canopy, 8 hoisting points are selected, the crane station is reasonably arranged, and the whole hoisting is in place at one time. The safety, efficiency, and accuracy of steel structure space frame canopy installation are realized.

1 The reference space frame unit is assembled on the ground

First of all, the reference space frame is installed. First, three upper-chord space frame units and two lower-chord space frame units are installed as the reference space frame. The lower string space frame and the ball assembly, according to the number of components, pad the plane of the lower string ball, the lower string rod and the ball are connected and tightened in place. The assembly of the belly rod and the bowstring ball, according to the belly rod and the bowstring ball should form a down four corner cone, the bowstring ball is installed in place first, and then connected to the belly rod; The connection between the belly rod and the upper chord ball must be tightened in place at one time, but the connection between the belly rod and the lower chord ball cannot be tightened in place at one time, mainly for the installation of the upper chord rod release service. The assembly of the upper chord space frame is transmitted from inside to outside according to the installation sequence of the upper chord rod. The upper chord rod and the ball should be tightened with the belly rod and the lower chord ball.

FIG. 1 Assembling and forming of steel space frame

FIG. 1 Assembling and forming of steel space frame

2 Install the space frame truss bolt-ball node

The installation workers sit on the node, and after the high-strength bolts are aligned with the screw holes on the steel, adjust the tightness of the bolts and then tighten them in groups to check the deflection of the bolt ball node of the space frame. Whether it meets the design and construction specifications of the space frame can be controlled by adjusting the size of the upper and lower strings. After assembling each unit node, check the tightness of the bolts with the afterburner. After the space frame is installed in a certain area, the position error of the space frame is detected by theodolite and level while it is installed, and the lower chord is supported by temporary support to correct the lower chord elevation. After the space frame inspection and adjustment, retighten the high-strength bolts of the space frame.

3. The overall assembly of the steel space frame adopts the unit extension bulk method, which expands to all sides along with the assembled benchmark space frame. The above method is used to conduct a comprehensive inspection after installing 2-3 space frame units, and the inspection should repeat the nut of each rod to see if it is loose. This method until the completion of all installation, the entire space frame installation, re-check the fastening bolts again, and after adjustment, remove the temporary support. In the whole process of space frame installation, special attention should be paid to the padding of the lower string ball, the accuracy of the axis, the control of the tightening degree, deflection, and geometric size of the high-strength bolt. The tightening degree of the high-strength bolt is generally based on the principle of no loose nut.

4 steel space frame hoisting and forming

The height of the aluminum-plastic plate at the edge of the space frame is 1.6m, and the lifting height of the bottom surface of the space frame is 6.5m. In order to prevent the boom from colliding with the edge of the space frame in the process of lifting, the safe distance between the space frame and the boom after lifting to a predetermined height is 1.5m. According to the size of the 50T truck crane, the distance between the edge lifting point and the wire rope lifting point is 7.5m, the length of the crane arm is 21.59m, and the included Angle is 64° and the operating radius is 9.5m. The working radius of the 50-ton truck crane is 10m and the length of the crane arm is 25.4m to meet the hoisting requirements. Choose 8 lifting points according to the shape, center of gravity, and process requirements of the steel space frame. The selection of lifting points must ensure that the steel space frame structure will not be deformed, so that the steel space frame structure is always stable in the process of lifting. During the lifting operation, check that the wire rope and the lifting point are firmly connected, then the crane will lift slowly. Be aware of the balance of the sling and component, and the lifting action of the four cranes will be consistent; When the space frame is lifted 50cm above the ground, stop lifting, observe the stress situation of ropes and other places, and continue to lift evenly and slowly after confirmation.

FIG. 2 Hoisting of steel space frame canopy

FIG. 2 Hoisting of steel space frame canopy

5 Hoisting in place

The four cranes rise evenly and slowly. Careful observation should be made in the process of lifting to prevent the space frame from colliding with the pillars, and the eight sliding ropes fixed on the four corners of the space frame are tightened in a symmetrical direction to prevent the collision between the steel plate net and the crane arm. When the lifting height exceeds the top of the column, the crane slowly shifts and adjusts to ensure accurate lifting in place; When lifting, attention should always be paid to the command of hoisting commanding personnel. Standing below the steel space frame is strictly prohibited, and non-construction personnel is strictly prohibited to enter the site. Lifting is commanded by one person.

6 the conclusion

Based on the ground in advance assembling steel structure rack tent, the integral lifting construction method of multimachine lift crane, multipoint stance and reliable construction technology, construction of high precision, safety and reliability, effectively completed the steel structure rack tent installation, reduced the overhead working time, greatly reduces the construction safety hidden trouble, shortening the time limit for a project, increase the economic benefit, It has accumulated valuable experience for the whole hoisting of large-area and large-span components.

About Us

About Us 2022-06-20

2022-06-20