First, foreword

The coal conveyance belt spans a long route, and the amount of steel used in the trestle is large, so the amount of steel used in the trestle becomes the main index of steel used in the workshop. If the problems of modeling, calculation, and installation can be solved, the amount of steel used in the trestle of the coal conveyance belt can be decreased obviously, and the structural stiffness can be enhanced.

Second, replace the truss trestle with a space frame trestle

FIG. 1 Coal Handling Systems

1. The proposal for coal transport trestle

The steel truss trestle is a plane structure, which requires the horizontal support system and end door frame to form the overall stability and seismic capacity. The steel beams on the floor of the inclined trestle are bidirectional and uneconomical. How to optimize the design of the coal trestle has attracted the attention of designers. The engineering example shows that it is very advantageous to use the space frame structure instead of the large-span truss structure, and the exposed space frame structure of the trestle is used to support the pipeline and cable corridor, which eliminates the supporting structure of the pipeline and cable corridor along the line.

2. Form of space frame trestle

(1) The closed truss trestle structure applied to the closed coal transport trestle can be divided into box truss, floor flat truss, and light steel vault;

(2) Open-air network trestle For open-air coal transport trestle platform, because there is no side seal, the use of single layer flat network frame. The trestle column of the space frame trestle can be a steel column or reinforced concrete column.

Third the design of the trestle of the coal transport belt

3. The design of the box truss trestle bridge

(1)Calculation model of box space frame trestle bridge

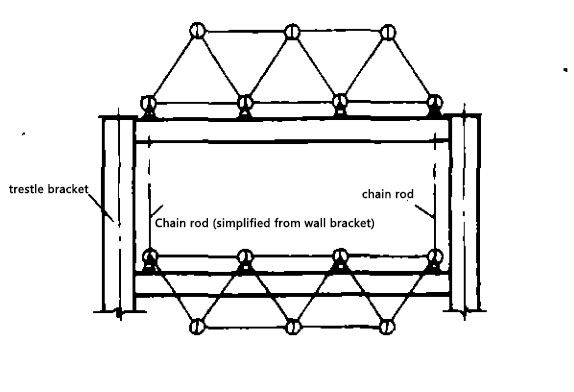

(2) Double deck space frame truss bearing force trestle: composed of floor network frame, roof network frame, both sides of the external hanging wall frame, in fact, two layers of coordinated force plate network frame. According to the floor space frame and roof space frame two independent flat space frames (multi-span according to the continuous space frame design), at the same time, it is necessary to simplify the stack hanging wall into a pull rod to coordinate the deformation of the two. This structural form is simple to calculate, but most of the floor and roof space frames are deformation control systems. See FIG. 2 for a section of the trestle bridge bearing double deck space frame.

FIG. 2 Trestle bridge with double deck space frame bearing capacity

(2) Container rack bearing force trestle: by floor space frame, roof space frame, and two side space frame together to form a closed overall box rack (multi-span according to the continuous space frame design). The overall stiffness of this network frame is large and the economy is good. The section of the load-bearing trestle is shown in Figure 2(a). According to the actual modeling needs, can consider the side and roof space frame arch or another cross-section form, and the floor space frame together to form the overall box space frame.

2. Floor structure form of box network trestle

The width of the trestle bridge is generally 6-9m, and the floor space frame is between 2.2mx2.2m and 3.0mx3.0m. The floor is generally as follows:1) the floor adopts small prefabricated plates of the same size as the space frame to be directly laid on the support of the space frame, and the rigid surface layer of 40mm thick steel wire mesh fine stone concrete is laid on it; 2) The floor is supported by the space frame and laid with steel beam – concrete slab.

3. Enclosure of the roof and side of the trestle, the roof and side of the trestle generally expose the network frame, and use the inner seal of the profiled steel plate. The outer surface of the space frame can achieve a better visual effect, and the inner sealing of the profited steel plate makes the bridge box neat and regular and can reduce the enclosure area.

Fourth the installation of the trestle of the coal transport belt

The installation of the space frame can generally use the following methods: (1) high-altitude bulk method; (2) strip or block installation method; (3) upper slip method; (4) overall lifting method; ⑤ Overall lifting method; ⑤ Integral jacking method. The route of the trestle is long and generally is high span. The installation of the space frame trestle is not recommended to adopt the high altitude bulk method, strip or block installation method, and high altitude slip method.

Fifth, the economic performance of the space frame coal transport trestle

The trestle materials mainly include steel for the main skeleton, steel for the roof beams, and materials for the floor panels. According to the statistical comparison of the amount of steel used in the steel truss trestle and the box space frame trestle of the 300MW generator set, it can be seen that:

1) Compared with the main stress truss system of steel truss trestle, the main stress truss system of box truss trestle can save about 18%~20%

2) The floor beam of steel truss trestle has a large span and biaxial stress, which accounts for a large proportion of steel used in the trestle, while the box space frame trestle does not need floor beam, which can save 27%~35% of the steel used only. The converted thickness and reinforcement of the prefabricated small ribs of the box and truss trestle are similar to that of the prefabricated small trough plates of the truss trestle, so the truss trestle saves the floor beam, but the cost of the floor slab does not increase.

3) Compared with the steel truss trestle, the span of the roof steel beam is reduced from 6~9m to about 2.5m, and the roof steel beam and purlin can be saved nearly half; 4) The network frame of the coal transport trestle is exposed, and the side and top surface are sealed inside, reducing the enclosure area by about 15%.

It can be seen that compared with steel truss trestle, the overall steel consumption per meter can be saved by about 37%. According to the total length of 550m, the width of 7.8m, and the span of 24~30m, the steel can be saved about 263~296t. A coal conveyance trestle is a common structure in coal-fired power plants and coal systems.

About Us

About Us 2022-10-21

2022-10-21