1 Glass Roof Project Overview

The total construction area of the Galaxy SOHO project is about 219,387m; The main body of the building adopts a reinforced concrete frame structure, with a height of 67.5m, 15 floors above ground, and 3 floors underground. The building is a high-end commercial office complex building, and the building category is a high-rise building. The seismic design anti-intensity is 8 degrees, the fire resistance rating is level 1, the structural safety rating is level 1, and the designed service life is 50A, as shown in Figure 1.

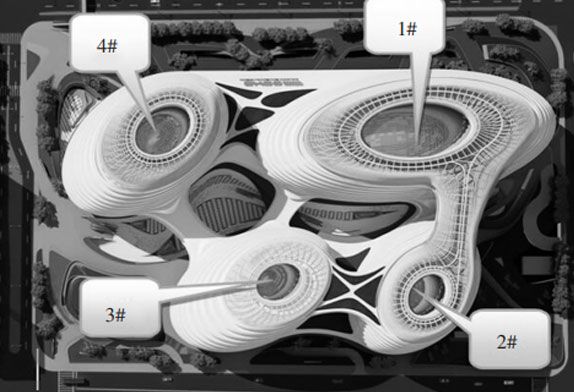

FIG.1 Skylight Glass Dome Roof

The decoration works of the project include glass curtain walls aluminum curtain wall stone curtain wall glass lighting roof and steel structure decoration louver maintenance safety rope guide outdoor glass railing and outdoor building enclosure and other glass roof and net shell support system design to ensure the realization of architects The design modeling determined by the curtain wall consultant is for the purpose of improving the advancement of each system of the project, especially the requirements of water tightness, air tightness, safety and stability of the appearance effect; At the same time, as far as possible to consider the rationality of its construction and installation components with the technology of the replaceable decorative plate.

3. Distribution and structure of skylight glass roof system

3.1 Distribution of Lighting Glass Roof The lighting roof system is located in the lighting part of the fourth tower atrium roof, with a total of 4 pieces.

FIG.2 Location distribution of skylight dome roof

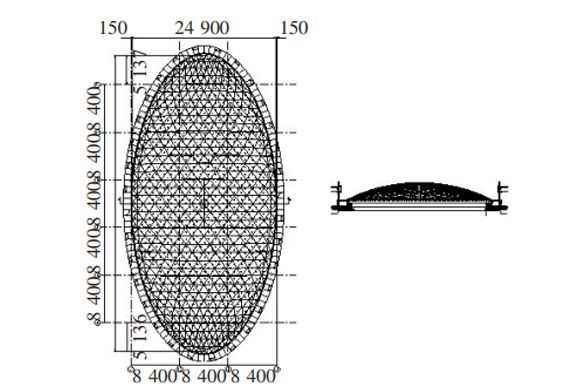

The skylight dome glass roof is a sunken ellipsoid shape (FIG. 3), which is assembled by triangular glass plates with side lengths of 1747mm and 2095mm and other sizes (FIG. 4).

FIG.3 Example of plane section of lighting roof (1# Lighting roof)

FIG. 4 Outdoor (left) and indoor (right) side view of the lighting skylight roof

3.2 Structure of skylight dome glass roof

The lighting top layer system is a small unit hidden frame structure, the surface layer glass is hollow laminated toughened glass, the main support system is single layer reticulated shell structure system; The aluminum alloy pad frame is fixed with the main support structure through screws, the surface layer glass is bonded with the aluminum alloy frame by structural glue, and then the surface layer system is pressed and fixed on the aluminum alloy pad frame by the aluminum alloy pressing block; The joints of the glass surface layer are made of weather-resistant sealant, and the connection part of the triangular glass tip is decorated with stainless steel gland, and the exterior decoration effect is excellent. The roof is equipped with a safety rope system to provide safety measures for cleaning and maintenance personnel.

A large amount of water is deposited on the surface and joint of the glass ceiling; Even if there is leakage of local glue joints or condensation water generated on the glass interior side of the lighting roof, it can be orderly discharged to the main body drain pipe through the aluminum alloy mat frame connected with the sink, and then centrally recycled or discharged to the outdoor.

This design is good for ensuring the water tightness and air tightness of the skylight roof Stainless steel gland is decorated on the outside of the triangular junction of the glass. The stainless steel gland is hexagonal. It is connected and fixed by stainless steel self-tapping nails and the transition support in the middle of the glass joint. Aluminum alloy inserts are used for continuous lap connection to ensure that a small amount of water can be drained in any direction in the aluminum alloy cushion frame connection tank; the Aluminum alloy gasket frame connection sink is fixed on the upper surface of the steel structure. An aluminum folding sheet is used to glue tight joints at the multi-direction junction. A continuous drainage ditch system is formed in the whole roof, and drainage pipes are set at the edge of the skylight.

The joint structure of the lighting apex Angle stainless steel drainage gutter is set around the skylight roof to seamlessly and reliably connect with the main drainage system; Stainless steel grating is arranged above the drainage ditch for convenient maintenance.

4 Precautions and important protective measures

1)The lighting roof of the project is a spatial shape, and rhino software is used to model the whole project in the design and construction process, so as to analyze and design the local structure in detail, so as to ensure the accuracy and efficiency of the engineering design, and provide reliable guarantee for the construction quality

2)The supporting system of the lighting roof adopts a single-layer reticular shell structure, which is composed of six steel beams connected by independent steel columns. Tower cranes are used for lifting to ensure that the center line of the load-bearing steel beams is consistent with the center line of the curtain wall, and the center of the elliptical screw hole is consistent with the position of the designed connecting bolts. Carefully check the deviation caused by the welding process to ensure the installation accuracy of the glass surface layer of the skylight roof; During the construction, the strength and detection frequency of steel structure installation measurement and monitoring is increased, and the firmness of embedded parts or anchoring steel plates is carefully checked. The installation position and height of each component are strictly in accordance with the requirements of wiring positioning and design drawings to ensure the accuracy of installation.

3) Must ensure that the joint between the glass plate is a flat transition, and can not appear stage difference and water storage, resulting in the existence of leakage hidden dangers.

5 conclusion

The design quality and construction precision of skylight roofs are the important guarantee conditions to realize their waterproof performance. The design and construction of the glass lighting roof system represent a high level of spherical lighting roof system at present. In the design, the influence of complex building shapes on the overall drainage is fully considered. Through the mature and reliable design scheme combined with excellent sealing materials and the application of 3D modeling technology, a better waterproof effect is achieved.

About Us

About Us 2022-10-24

2022-10-24